Liquid methane filling-up system

A filling system, methane technology, applied in the field of filling systems, can solve the problems of high risk of testing and easy leakage of the testing system, and achieve the effect of improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The invention satisfies the safety requirements of the methane filling of the aerospace engine test bench and the discharge of residual methane during the test run and after the test run by establishing a whole set of liquid methane filling system.

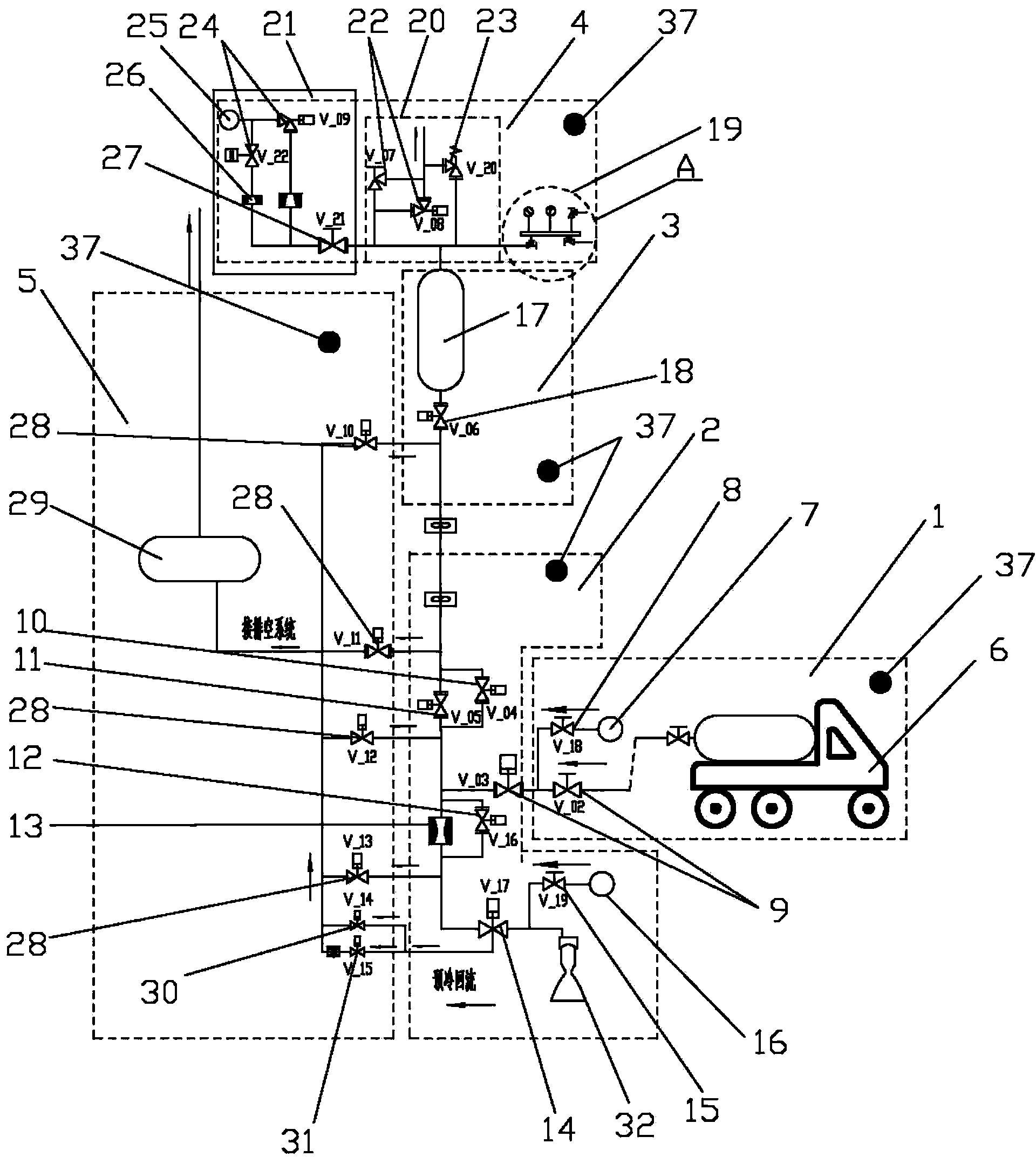

[0031] combined with figure 1 To describe the system:

[0032] A liquid methane filling system is divided into five parts, namely: filling unit 1, pre-testing unit 2, container unit 3, pressurization and exhaust unit 4, and recovery and discharge unit 5;

[0033] Among them, the filling unit 1 includes a methane transport tank car 6, a first nitrogen gas source 7, a system filling blow valve (V18) 8, and a system filling valve 9 (V02 or V03); the outlet of the methane transport tank car 6 is connected to the system filling Injection valve 9 (V02 or V03) inlet; one end of the system filling blow valve (V18) 8 is connected to the first nitrogen gas source 7, and the other end is connected to the outlet of the system filling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com