Recovery of hydrogen from refinery and petrochemical light ends streams

a technology of light end streams and hydrogen, which is applied in the direction of cold treatment separation, liquefaction, lighting and heating apparatus, etc., can solve the problems of releasing carbon dioxide into the atmosphere, the byproduct hydrogen is not enough to meet the demand, and the cost of hydrogen is about three times as much, so as to achieve high yield and purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

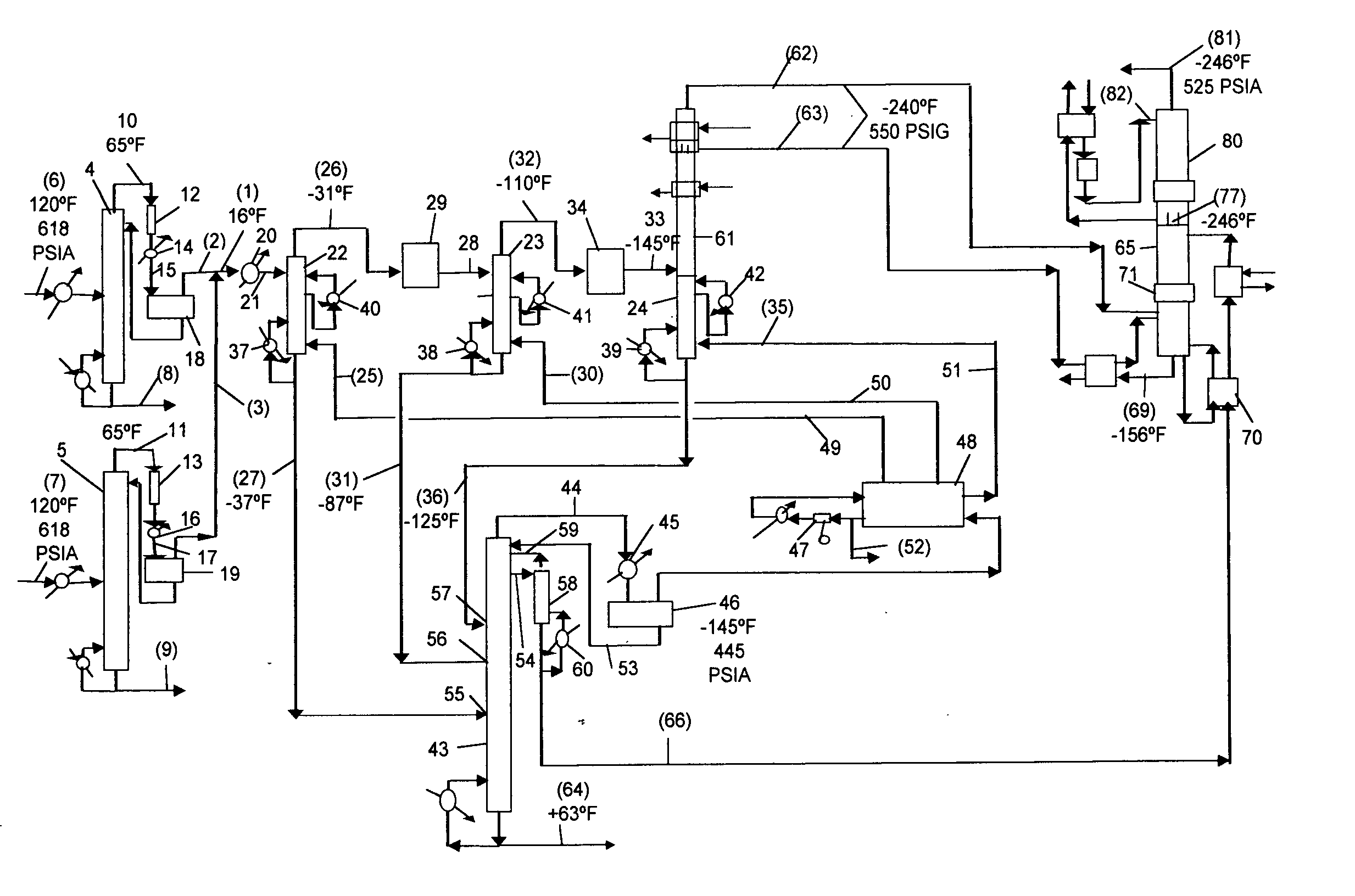

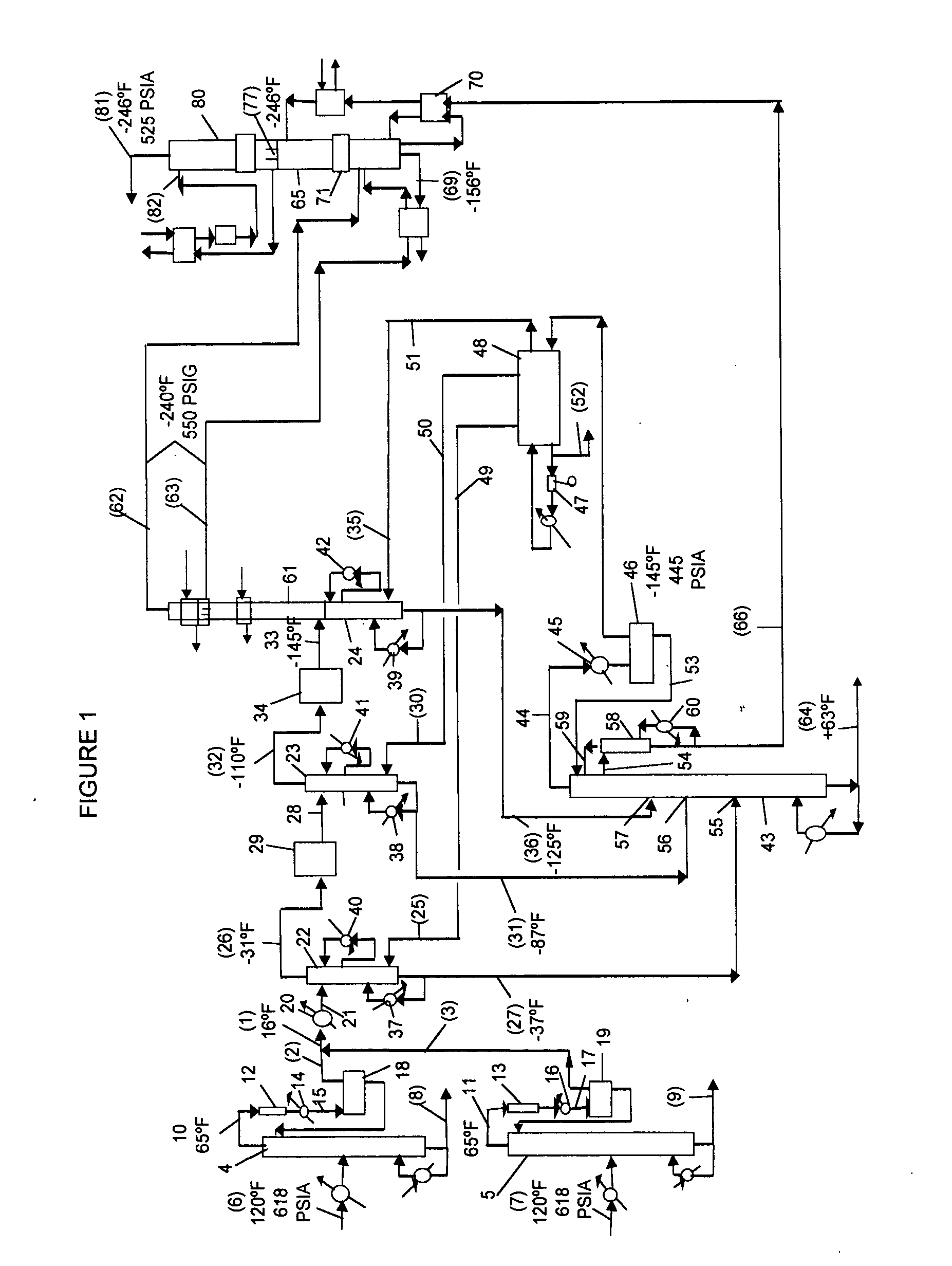

[0016]FIG. 1 is a simplified flow plan of the process of the present invention in a preferred embodiment. Table 1 presents temperatures, pressures, flow rates and compositions for key process streams that are indicated in FIG. 1.

[0017]FIG. 1 does not show auxiliary equipment necessary to operate the process of this invention but that is not critical to describing the invention, such as pumps, valves, and some heat exchangers; these equipment items are well understood by process engineers to be required.

[0018] The feed to the process of this invention is a hydrogen bearing stream 1 that contains propane and lighter hydrocarbons. The feed to the process also contains non condensable gases—including nitrogen and carbon monoxide. Non condensable gases complicate recovery of hydrogen.

[0019] The feed stream for the process of the present invention 1 is derived from the overheads 2,3 of prefractionator distillation columns 4,5 commonly used in petroleum refineries. The feeds 6,7 to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com