Integrated NGL recovery and liquefied natural gas production

a technology of liquefied natural gas and ngl, which is applied in the field of methane separation, can solve the problems of not being able to provide reflux derived from both ngl fractionation and partially condensed scrub column overhead, and the difficulty of recovering heavy hydrocarbons by the scrub column becomes more difficult, so as to maximize the benefit and improve the separation effect of ethane and propan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

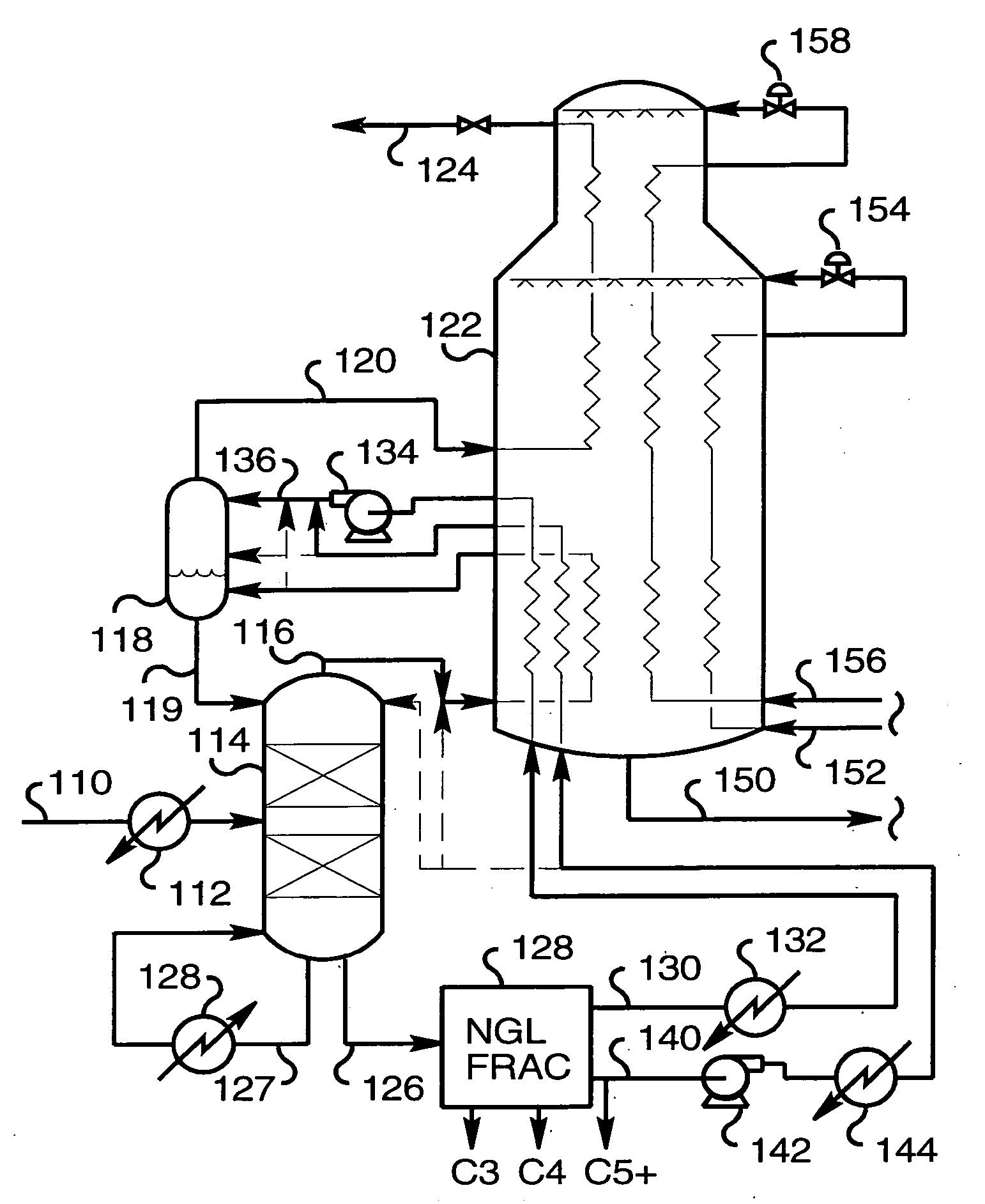

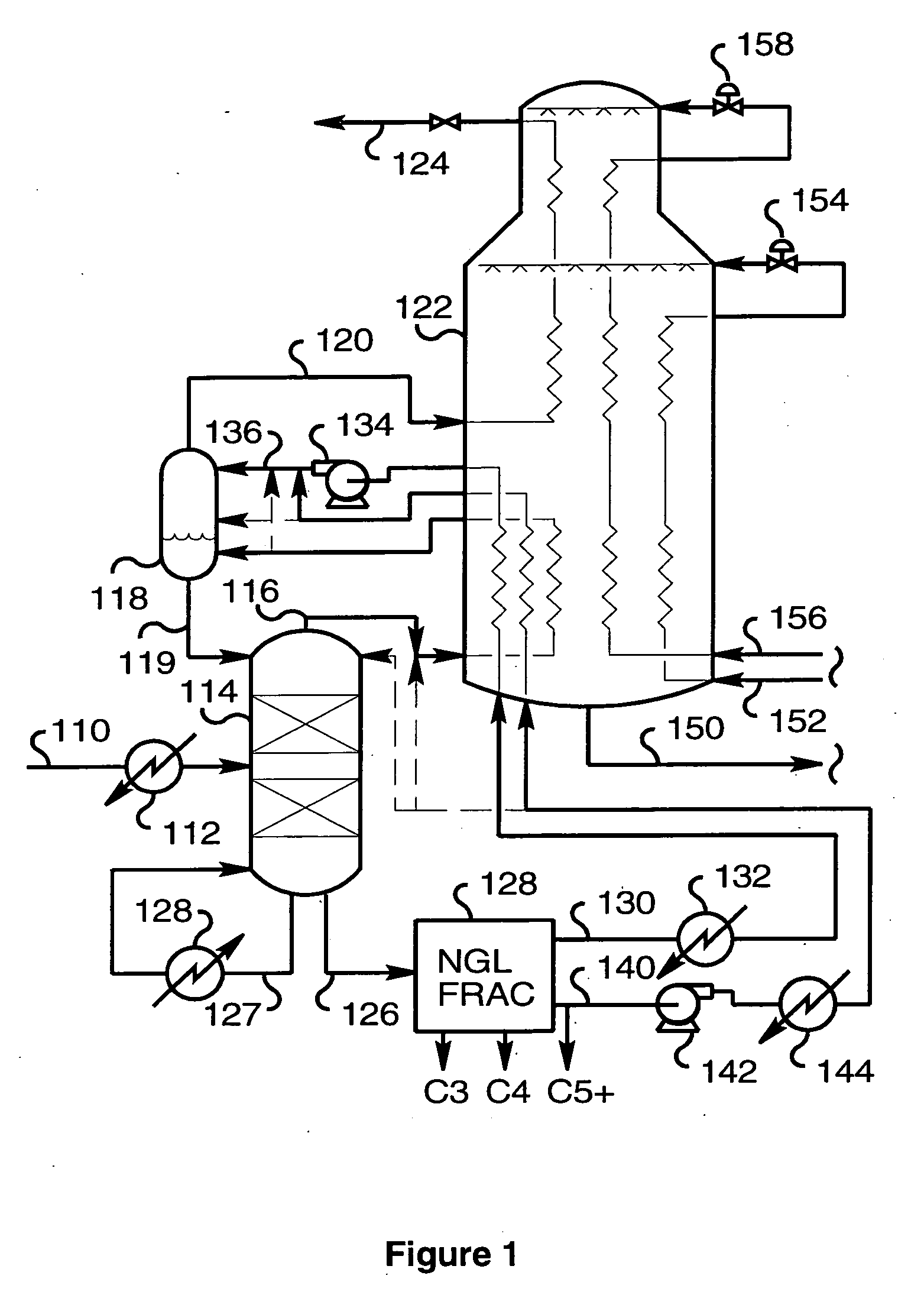

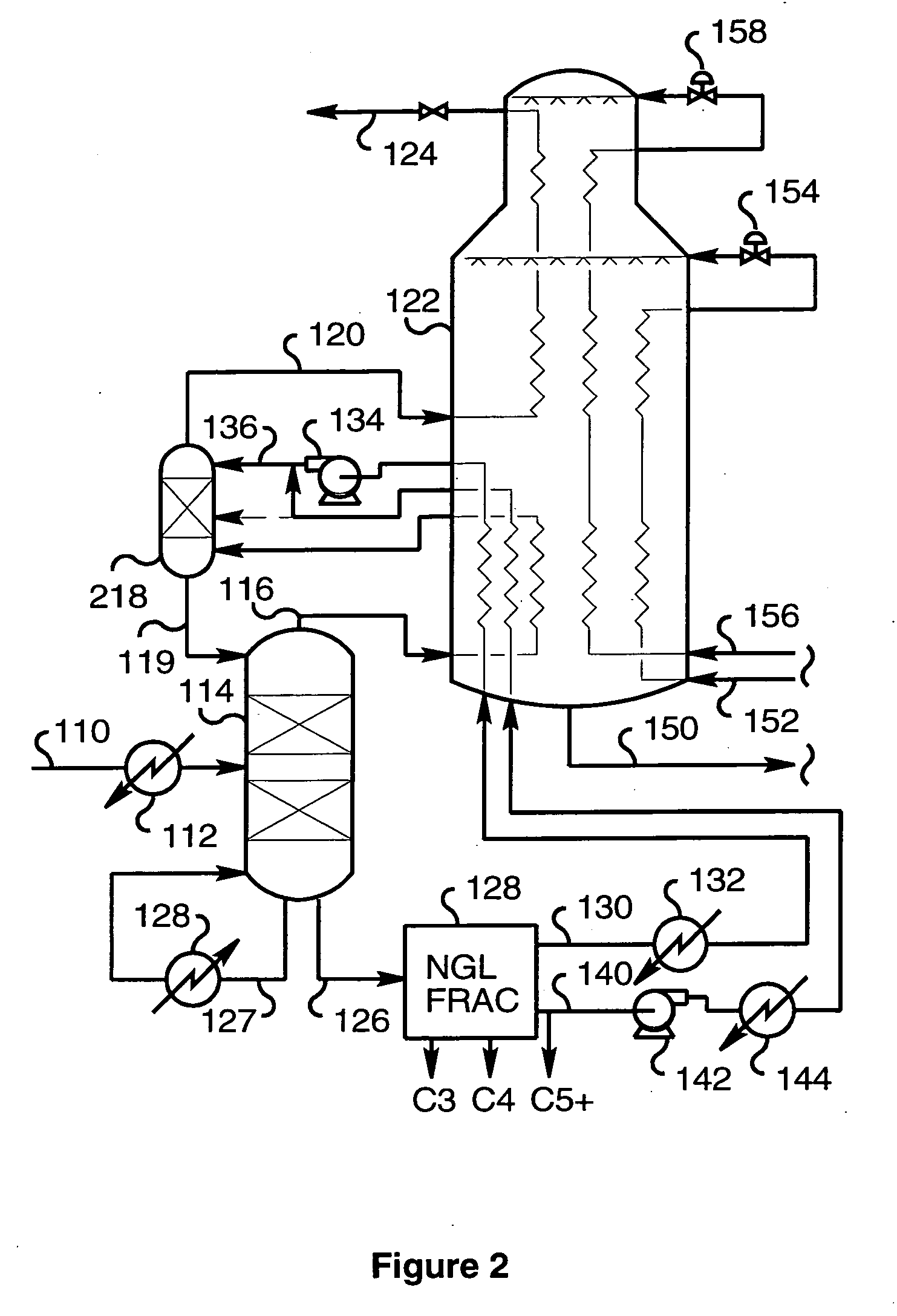

[0125] Using the embodiment of FIG. 3, 97,904 lbmol / h (44,408.5 kgmol / h) of a pre-purified natural gas stream 110 at 950 psia (6.5 MPa) is cooled in heat exchanger 112 by three stages of propane cooling to −32.3° F. (−35.7° C.) and fed to the scrub column 114. This feed stream 110 contains 0.6% nitrogen, 84.8% methane, 7.3% ethane, 4.4% propane, 0.7% isobutane, 1.5% butane, 0.3% isopentane, 0.2% pentane, and 0.2% hexanes. The column 114 operates at 840 psia (5.8 MPa) and has an intermediate reboiler heated by 40% of the stream 110 bypassing the first two stages of propane cooling and a bottom reboiler 128 at about 130° F. (55° C.). Column overhead 116 is cooled from −62.3° F. (−52.4° C.) to −77.5° F. (−60.8° C.) in the warm bundle of the main heat exchanger 122 and introduced into the reflux drum 118 as a two-phase stream containing about 15% of liquid. Scrub column bottoms stream 126 is sent to the fractionation systems 128, consisting of a series of distillation columns comprising...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com