Device for recovery of light hydrocarbons and co-production of LNG from tail gas of Fischer-Tropsch synthesis and method thereof

A technology for Fischer-Tropsch synthesis and tail gas synthesis, which is applied in chemical instruments and methods, preparation of liquid hydrocarbon mixtures, hydrocarbons, etc., and can solve the problem of reducing the partial pressure of effective components, high equipment investment and operating costs, and increasing Fischer-Tropsch synthesis. Reactor system load and other problems, to achieve the effect of improving yield and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

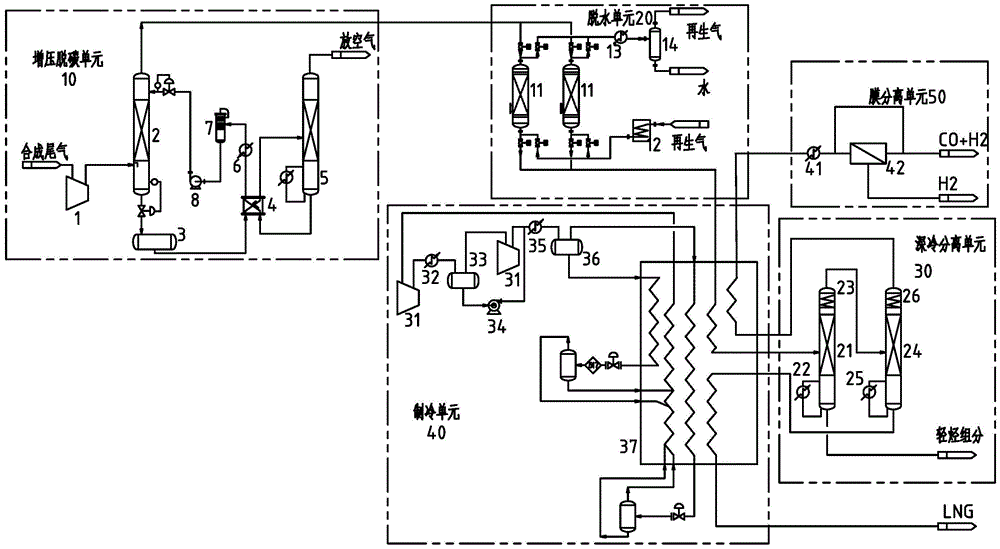

[0023] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

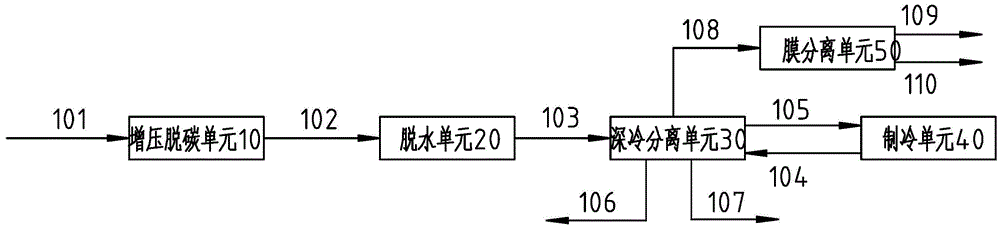

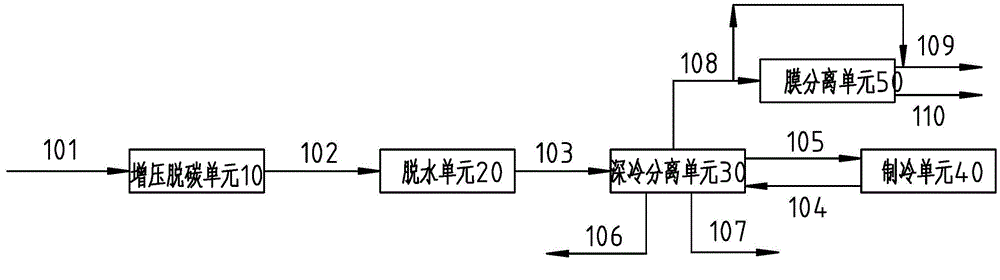

[0024] like image 3 As shown, the present invention is a device for reclaiming light hydrocarbons and co-producing LNG from the tail gas of Fischer-Tropsch synthesis. Unit 40.

[0025] The pressurized decarbonization unit 10 is composed of a tail gas compressor 1, a carbon dioxide absorption tower 2, a rich amine liquid flash tank 3, a poor-rich amine heat exchanger 4, a carbon dioxide desorption tower 5, a lean amine cooler 6, and a lean amine filter 7 and a lean amine booster pump 8; the booster decarburization unit 10 is used to boost the synthesis tail gas to 4.0MPa-6.0Mpa. The pressurized decarburization unit 10 can choose chemical absorption method, physical absorption method or physical-chemical absorption method. Typical chemical absorption methods are: monoethanolamine method (MEA), diethanolami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com