Technology for production of gasoline and combined production of natural gas and hydrogen through methanol synthesis of coke oven gas

A methanol synthesis and natural gas technology, applied in the petroleum industry, the preparation of liquid hydrocarbon mixtures, gas fuels, etc., can solve the problems of insufficient gasoline heat, complex process, pollution, etc., to avoid waste of excess heat, reduce methanol rectification units, The effect of increasing economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

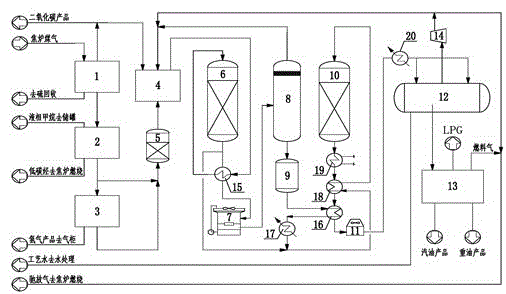

Method used

Image

Examples

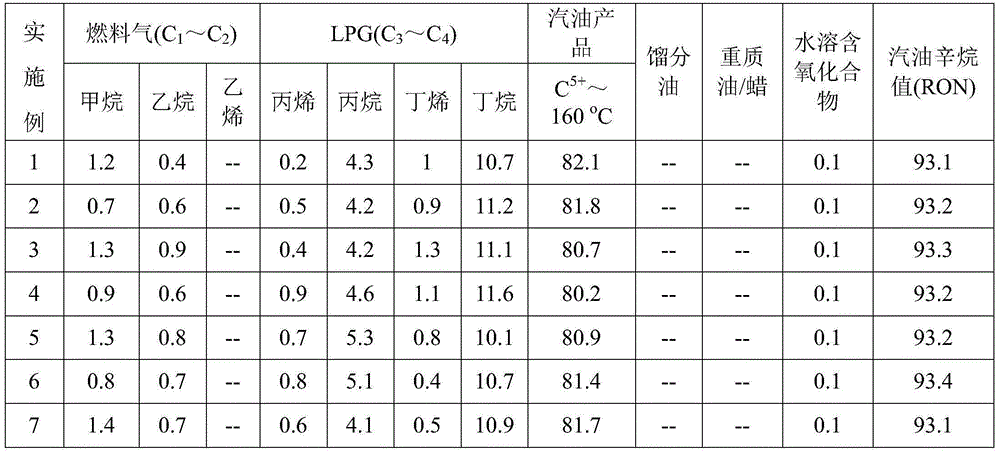

Embodiment 1

[0034] (1) The volume composition after dust removal and deoiling is H 2 60%, CO5.3%, CO 2 2.7%, CH 4 23.7%, N 2 4.6% and C n H m 3.7% of the coke oven gas enters the low-temperature methanol system 1, where the sulfur and carbon dioxide in the coke oven gas are removed at a temperature of -60°C and a pressure of 4 MPa, and the removed sulfur is sent to the sulfur recovery system for removal. 45% of the volume fraction of the removed carbon dioxide is mixed with the coke oven gas from the desulfurization tank 5 to enter the synthesis gas compressor unit 4, while the remaining 55% of the carbon dioxide is sold as a product, and the coke oven gas after the removal of sulfur and carbon dioxide enters deep cooling Methane separation 2. After cooling the coke oven gas to -70°C, the low-carbon hydrocarbons containing ethane, propane and a small amount of carbon dioxide separated at 4.0MPa are sent to the coke oven for combustion, and then the gas phase is further cooled to -150°C. 4.0...

Embodiment 2

[0039] (1) The volume composition after dust removal and deoiling is H 2 59.6%, CO5.0%, CO 2 3.0%, CH 4 25.8%, N 2 3.0% and C n H m 3.6% of the coke oven gas enters the low-temperature methanol system 1, where the sulfur and carbon dioxide in the coke oven gas are removed at a temperature of -50°C and a pressure of 3.8 MPa, and the removed sulfur is sent to the sulfur recovery system. 38% of the volume fraction of the removed carbon dioxide is mixed with the coke oven gas from the sulfur protection tank to enter the synthesis gas compressor unit 4, while the remaining 62% of the carbon dioxide is sold as a product. The coke oven gas after the removal of sulfur and carbon dioxide enters the deep Cold methane separation 2. After the coke oven gas is cooled to -74°C, low-carbon hydrocarbons containing ethane, propane and a small amount of carbon dioxide are separated at 3.8MPa and sent to the coke oven for combustion, and then the gas phase is further cooled to -155°C. The LNG prod...

Embodiment 3

[0044] (1) The volume composition after dust removal and deoiling is H 2 57.8%, CO5.7%, CO 2 2.6%, CH 4 24.2%, N 2 5.8% and C n H m 3.9% of the coke oven gas enters the low-temperature methanol system 1, where the sulfur and carbon dioxide in the coke oven gas are removed at a temperature of -40°C and a pressure of 3.6 MPa, and the removed sulfur is sent to the sulfur recovery system. 36% of the volume fraction of the removed carbon dioxide is mixed with the coke oven gas from the sulfur protection tank to enter the synthesis gas compressor unit 4, while the remaining carbon dioxide is sold as a product, and the coke oven gas after the removal of sulfur and carbon dioxide enters the cryogenic methane separation 2. After the coke oven gas is cooled to -76°C, the low-carbon hydrocarbons including ethane, propane and a small amount of carbon dioxide are separated at 3.6MPa and sent to the coke oven for combustion, and then the gas phase is further cooled to -160°C and separated at 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com