System and method for preparing hydrogen rich gas and liquid methane

A liquid methane and hydrogen-rich technology, applied in refrigeration, liquefaction, liquefaction, hydrogen separation, etc., can solve the problems of waste and consumption, and achieve the effects of saving power consumption, good rectification effect, and large operating flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

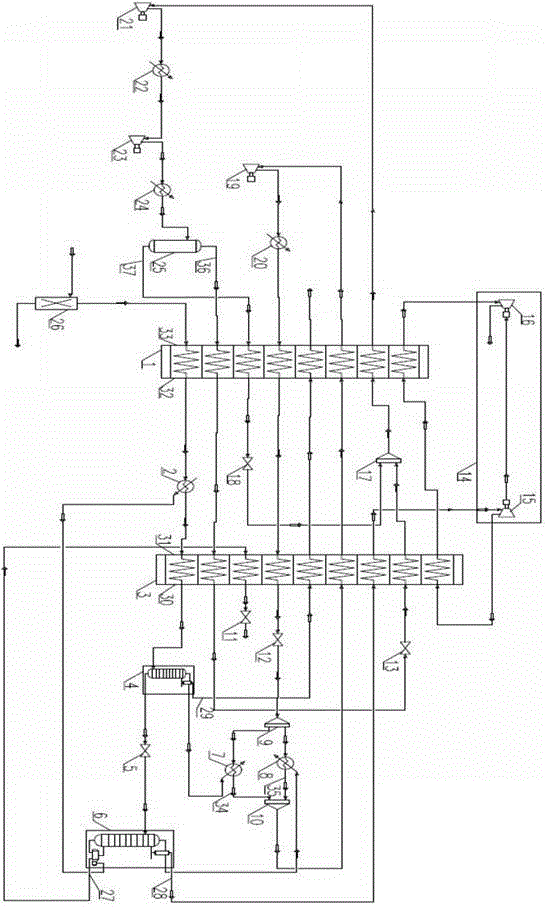

[0028] like figure 1 As shown, a system for producing hydrogen-rich gas and liquid methane mainly includes a purge gas purification unit and a low-temperature liquefaction separation unit. The low-temperature liquefaction separation unit includes a liquefaction cold box system, a mixed refrigerant cycle compression system and a nitrogen cycle compression system; the liquefaction cold box system includes a first plate-fin heat exchanger 1, a second plate-fin heat exchanger Device 3, high-pressure rectification tower 4, low-pressure rectification tower 6, and exhaust gas expander 14; Described high-pressure rectification tower 4 tower tops are provided with first condenser 7, and described low-pressure rectification tower 6 tower bottoms are provided with There is an evaporator 2, and the top of the tower is provided with a second condenser 8; the mixed refrigerant cycle compression system includes a primary mixed refrigerant compressor 21, a primary cooler 22, a secondary mixed...

Embodiment 2

[0035] A method for producing hydrogen-rich gas and liquid methane. The synthetic ammonia or methanol purge gas with a pressure of 1.6MPa~7.0MPa passes through the purification unit 26, and the trace amount of CO in the purge gas is absorbed by the adsorbent in the purification unit. 2 and water are removed, and the relaxed gas after removing impurities enters the first plate-fin heat exchanger 1 and is cooled to 145K~165K, and enters the low-pressure rectification tower evaporator 2 as a heat source to be further cooled, and the temperature after cooling is 135K ~ 155K, enter the second plate-fin heat exchanger 3 and cool to 110K ~ 117K, the gas after cooling enters the high-pressure rectification tower 4 for rectification separation, and the purity obtained at the top of the high-pressure rectification tower is 91.4 %mol of hydrogen enters the cold end 30 of the second plate-fin heat exchanger and the cold end 32 of the first plate-fin heat exchanger to reflow and reheat to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com