A methanation process for producing synthetic natural gas from coal-based syngas

A technology for synthesizing natural gas and coal-based syngas, which is applied in the petroleum industry, gas fuel, fuel, etc., and can solve the problems of large circulating gas volume, increased equipment investment, and increased power consumption of circulating gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

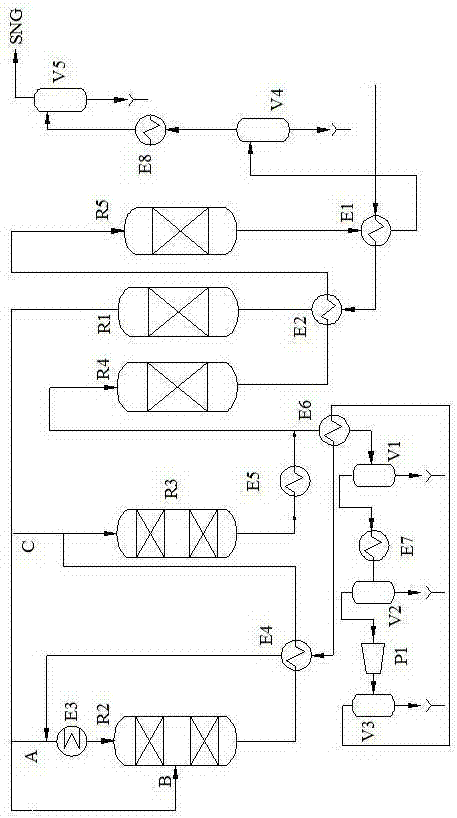

Embodiment 1

[0026] according to figure 1 As shown in the process flow, the pressure is 1.0MPa, and the space velocity is 10000h -1 of syngas and the total sulfur in the syngas is less than 0.1*10 -6 , scaling factor f=(n H2 -n CO2 ) / (n CO +n CO2 )=2.8, the obtained syngas composition (vol%) is: H 2 67.08, CH 4 9.2, CO2 1.17, CO 2 2.05,N 2 0.5. The synthesis gas is divided into three streams (fresh gas A, B, C). The fresh gas A is mixed with the gas that has been heat-exchanged by the circulating gas preheater E4 to form a reverse-stage intake air, and then enters the first stage after passing through the feed gas heater E3. In the first section of the methane synthesis reactor R2, the gas inlet temperature is 280°C, and the temperature rises to 510°C after the reaction. The gas from the first stage of reaction is mixed with the fresh gas B of the second stage to form the inlet gas of the first stage of reaction and the second stage, which enters the first methane synthesis reacti...

Embodiment 2

[0028] according to figure 1 As shown in the process flow, the pressure is 5.5MPa, and the space velocity is 20000h -1 of syngas and the total sulfur in the syngas is less than 0.1*10 -6 , scaling factor f=(n H2 -n CO2 ) / (n CO +n CO2 )=3.1, the obtained syngas composition (vol%) is: H 2 69.5, CH 4 8.21, CO19.84, CO 2 1.95,N 20.5. The synthesis gas is divided into three streams (fresh gas A, B, C). The fresh gas A is mixed with the gas that has been heat-exchanged by the circulating gas preheater E4 to form a reverse-stage intake air, and then enters the first stage after passing through the feed gas heater E3. In the first stage of the methane synthesis reactor R2, the gas inlet temperature is 280°C, and the temperature rises to 530°C after the reaction. The gas from the first stage of reaction is mixed with the fresh gas B of the second stage to form the inlet gas of the first stage of reaction and the second stage, which enters the first methane synthesis reaction ...

Embodiment 3

[0030] according to figure 1 As shown in the process flow, the pressure is 8MPa, and the space velocity is 30000h -1 of syngas and the total sulfur in the syngas is less than 0.1*10 -6 , scaling factor f=(n H2 -n CO2 ) / (n CO +n CO2 )=3.0, the obtained synthesis gas composition (vol%) is: H 2 68.5, CH 4 8.82, CO20.23, CO 2 1.95,N 2 0.5. The synthesis gas is divided into three streams (fresh gas A, B, C). The fresh gas A is mixed with the gas that has been heat-exchanged by the circulating gas preheater E4 to form a reverse-stage intake air, and then enters the first stage after passing through the feed gas heater E3. In the first section of the methane synthesis reactor R2, the gas inlet temperature is 280°C, and the temperature rises to 535°C after the reaction. The gas from the first stage of reaction is mixed with the fresh gas B of the second stage to form the inlet gas of the first stage of reaction and the second stage, which enters the first methane synthesis re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com