Process for preparing aromatic hydrocarbon from methanol by virtue of fixed bed

A fixed bed methanol technology, applied in the direction of producing hydrocarbons from oxygen-containing organic compounds, including molecular sieve catalysts, catalysts, etc., can solve the problems of high yields of low-carbon olefins and low yields of aromatics products, and reduce operating energy consumption. Effects of improving economy and reducing circulating air volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

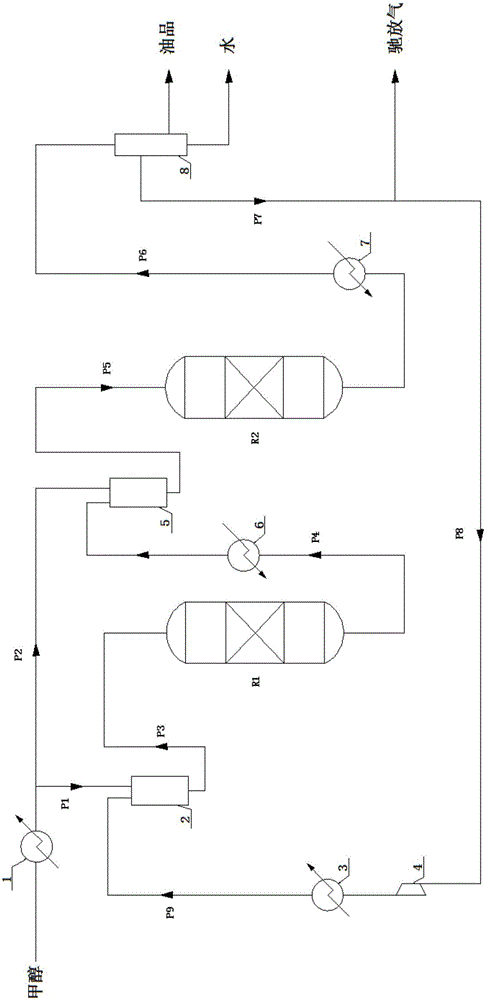

[0032] A 2-stage fixed-bed reactor process flow is adopted.

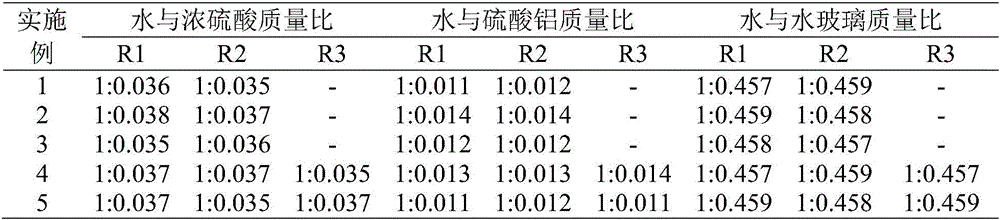

[0033] The preparation of the catalyst in reactor R1 takes place first. Concentrated sulfuric acid and aluminum sulfate are used to prepare aqueous solution A, wherein the mass ratio of water to concentrated sulfuric acid and aluminum sulfate is 1:0.036:0.011. Water glass, n-butylamine, and sodium hydroxide are used to prepare aqueous solution B, wherein the mass ratio of water to water glass, n-butylamine, and sodium hydroxide is 1:0.457:0.045:0.008. Under stirring conditions, an equal volume of solution A was added dropwise to solution B, and stirring was continued at room temperature for 24 h. Under airtight conditions, the temperature was raised to 120°C, and the stirring was continued for 1 hour, then the temperature was raised to 180°C, and the stirring was continued for 36 hours. The reaction kettle was taken out, and the product was filtered, washed until neutral, and dried to obtain ZSM-5 sodium molecular...

Embodiment 2、3

[0036] A 2-stage fixed-bed reactor process flow is adopted. The catalyst preparation method adopted in the reaction is the same as that of Example 1, and the specific preparation conditions are shown in Attached Table 1. Technological process is identical with embodiment 1 in the reaction process, and concrete technological condition sees attached table 2. The mass content of each component of the reaction product is shown in Attached Table 3.

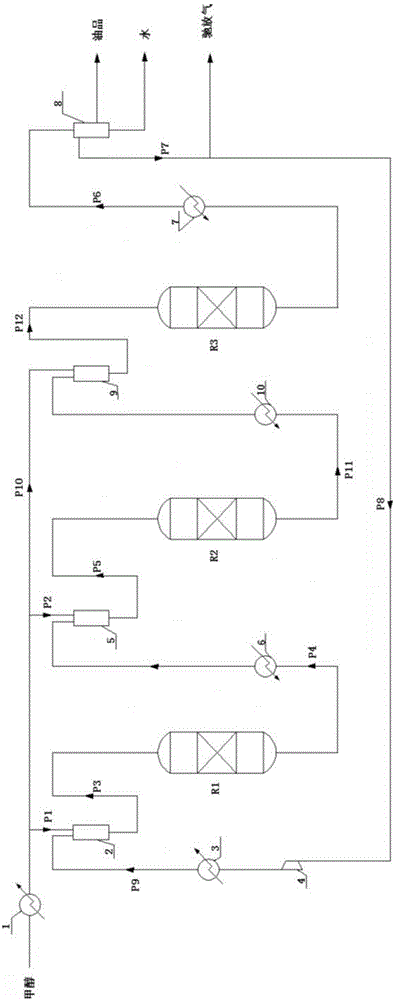

Embodiment 4

[0038] A 3-stage fixed-bed reactor process flow is adopted, and the reaction flow is as follows figure 2 . The catalyst preparation method adopted in the reaction is the same as that of Example 1, and the specific preparation conditions are shown in Attached Table 1. During the reaction process, methanol is heated by preheater 1 to become raw material gas, which is divided into 3 parts, and enters buffer tank 2, buffer tank 5 and buffer tank respectively through pipelines p1, p2 and p10 with a volume ratio of 1:1.2:1.4 9. The tail gas circulation gas enters the buffer tank 2 at the same time, the circulation gas and the raw material gas are mixed at a ratio of 1:6.1, and enter the reactor R1 through the pipeline p3, the inlet temperature is 400°C, the inlet pressure is 2MPa, and the space velocity is 40000h -1 , the height-to-diameter ratio of the R1 bed is 1:1.1, the reacted gas enters the waste heat boiler 6 through the pipeline p4, and then enters the buffer tank 5 to mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com