Method for preparing synthetic ammonia from low-H2/N2-ratio synthesis gas

A technology for H2-N2 and ammonia synthesis, which is applied in the preparation/separation of ammonia, production of bulk chemicals, etc., and can solve the problems of low utilization rate of synthesis gas and low ammonia yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

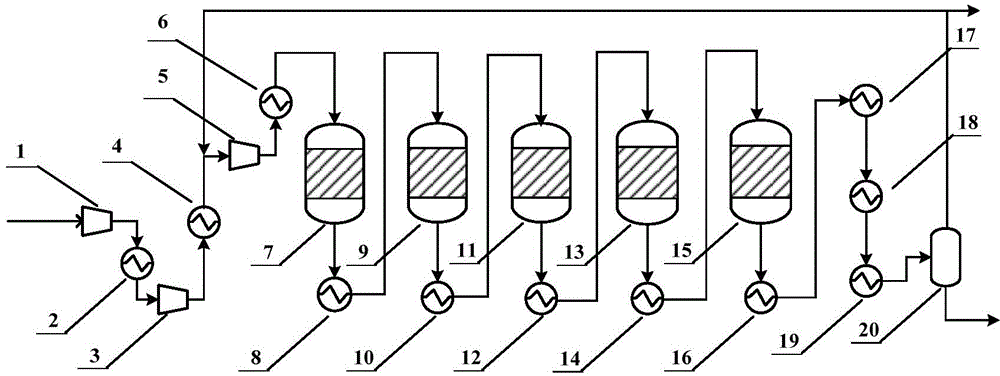

Method used

Image

Examples

Embodiment 1

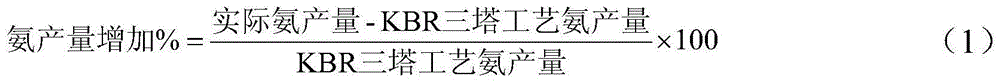

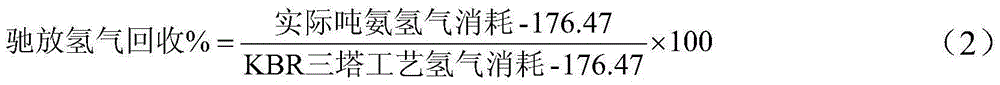

[0078] Fresh normal temperature low pressure syngas H 2 / N 2 The ratio is 3.00. According to the calculation of the KBR three-tower process, the pressure of synthesis gas entering the first iron-based catalyst reactor is 150atm, the temperature of synthesis gas entering the first iron-based catalyst reactor is 350℃, and the synthesis gas entering the second and third reactors The temperature of each iron-based catalyst reactor is 380℃, the circulating gas purge ratio is 4%, and the catalyst loading volume of the first iron-based catalyst reactor is 15m 3 , The first iron-based catalyst reactor has a catalyst loading capacity of 25m 3 , The first iron-based catalyst reactor has a catalyst loading capacity of 40m 3 , The final export ammonia concentration is 20.92%, and the production index is shown in Table 1.

[0079] Table 1 Reaction pressure 150atm, H 2 / N 2 =3.0 iron catalyst production index value

[0080]

Embodiment 2

[0082] Fresh normal temperature low pressure syngas H 2 / N 2 The ratio is 3.00, the pressure of synthesis gas entering the iron-based catalyst reactor is 150atm, the temperature of synthesis gas entering the iron-based catalyst reactor is 350℃, the temperature of synthesis gas entering the four ruthenium-based catalyst reactors is 360℃, and the circulating gas is released The proportion is 4%, and the iron-based catalyst reactor catalyst loading capacity is 15m 3 , The first ruthenium-based catalyst reactor has a catalyst loading capacity of 5m 3 , The second ruthenium-based catalyst reactor has a catalyst loading capacity of 6m 3 , The third ruthenium-based catalyst reactor catalyst loading capacity 7m 3 , The fourth ruthenium-based catalyst reactor catalyst loading capacity 9m 3 , The final export ammonia concentration is 24.80%, and the production index is shown in Table 2.

[0083] Table 2 Reaction pressure 150atm, H 2 / N 2 =3.0 production index value of iron string ruthenium c...

Embodiment 3

[0086] Fresh normal temperature low pressure syngas H 2 / N 2 The ratio is 2.95, the pressure of synthesis gas entering the iron-based catalyst reactor is 150atm, the temperature of synthesis gas entering the iron-based catalyst reactor is 350℃, the temperature of synthesis gas entering the four ruthenium-based catalyst reactors is 360℃, and the circulating gas is released The proportion is 4%, and the iron-based catalyst reactor catalyst loading capacity is 15m 3 , The first ruthenium-based catalyst reactor has a catalyst loading capacity of 5m 3 , The second ruthenium-based catalyst reactor has a catalyst loading capacity of 6m 3 , The third ruthenium-based catalyst reactor catalyst loading capacity 7m 3 , The fourth ruthenium-based catalyst reactor catalyst loading capacity 9m 3 , Into the first ruthenium-based catalyst H 2 / N 2 =2.52, the final outlet ammonia concentration is 25.52%, and the production index is shown in Table 3.

[0087] Table 3 Reaction pressure 150atm, H 2 / N ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com