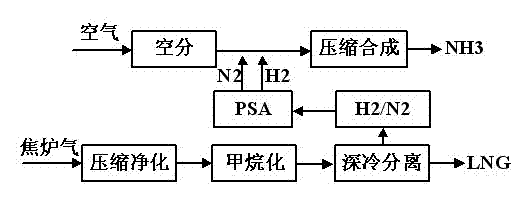

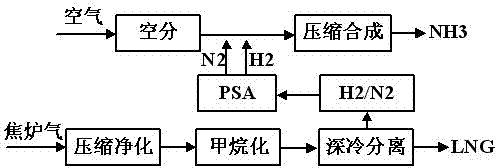

Technology for preparing liquefied natural gas and liquid ammonia by using coke oven gas

A technology of liquefied natural gas and coke oven gas, which is applied in the production of bulk chemicals, ammonia preparation/separation, petroleum industry, etc., and can solve the problems of low added value, low calorific value and low added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] The coke oven gas composition (vol%) of this embodiment is: H 2 57.6, CH 4 26.9, CO 7.2, CO 2 2.1,N 2 4.1,C 2 h 6 2.1. Coke oven gas volume is 50000Nm 3 / h, temperature 40°C.

[0065] (1) Compress coke oven gas to 0.5 MPa;

[0066] (2) Coke oven gas purification

[0067] The dry purification temperature swing adsorption method is adopted to remove tar, naphthalene, ammonia, sulfur and other impurities in the raw gas. Then enter the PDS method or PDS plus tannin wet desulfurization process, dry desulfurization process to remove the total sulfur in the coke oven gas to ≤0.1mg / Nm 3 , to obtain purified coke oven gas.

[0068] (3) Coke oven gas methanation:

[0069] A four-stage adiabatic methanation process with circulation is adopted.

[0070] The composition (vol%) of coke oven gas after methanation is: H 2 34.5, CH 4 59.5,N 2 6.0, CO 2 ≤50ppm. The amount of synthetic natural gas after methanation is 33950Nm 3 / h, temperature 40°C. Here, 3.8MPa...

Embodiment 2

[0081] The coke oven gas composition (vol%) of this embodiment is: H 2 57.6, CH 4 26.9, CO 7.2, CO 2 2.1,N 2 4.1,C 2 h 6 2.1. Coke oven gas volume is 50000Nm 3 / h, temperature 40°C.

[0082] (1) Compress coke oven gas to 5.5 MPa;

[0083] (2) Coke oven gas purification

[0084] The dry purification temperature swing adsorption method is adopted to remove tar, naphthalene, ammonia, sulfur and other impurities in the raw gas. Then enter the PDS method or PDS plus tannin wet desulfurization process, dry desulfurization process to remove the total sulfur in the coke oven gas to ≤0.1mg / Nm 3 , to obtain purified coke oven gas.

[0085] (3) Coke oven gas methanation:

[0086] A three-stage no-cycle one-pass methanation process is adopted.

[0087] The composition (vol%) of coke oven gas after methanation is: H 2 34.5, CH 4 59.5,N 2 6.0, CO 2 ≤50ppm. The amount of synthetic natural gas after methanation is 33950Nm 3 / h, temperature 40°C. Here, 3.8MPa~10.0MPa...

Embodiment 3

[0098] The coke oven gas composition (vol%) of this embodiment is: H 2 57.7, CH 4 21.8, CO 8.83, CO 2 4.38,N 2 4.69, C 2 h 6 2.6. Coke oven gas volume is 50000Nm 3 / h, temperature 40°C.

[0099] (1) Compress coke oven gas to 2.5 MPa;

[0100] (2) Coke oven gas purification:

[0101] The dry purification temperature swing adsorption method is adopted to remove tar, naphthalene, ammonia, sulfur and other impurities in the raw gas. Then enter the PDS method or PDS plus tannin wet desulfurization process, dry desulfurization process to remove the total sulfur in the coke oven gas to ≤0.1mg / Nm 3 , to obtain purified coke oven gas.

[0102] (3) Coke oven gas methanation:

[0103] A two-stage adiabatic methanation process with circulation is adopted.

[0104] The composition (vol%) of coke oven gas after methanation is: H 2 15.9, CH 4 75.3,N 2 8.8, CO 2 ≤50ppm. The amount of synthetic natural gas after methanation is 26695Nm 3 / h, temperature 40°C. Here, 3....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com