Method of producing substitute natural gas from synthesis gas

A technology to replace natural gas and synthesis gas, applied in gas fuel, petroleum industry, fuel and other directions, can solve the problems of large amount of circulating gas and high energy consumption of compressors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

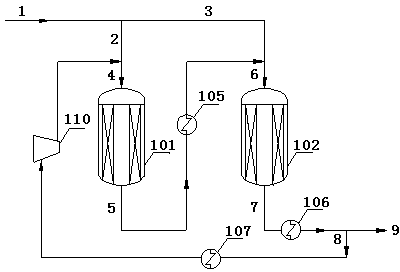

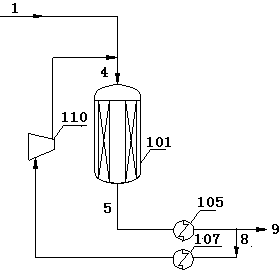

[0029] One billion Nm 3 / Year synthesis gas to replace natural gas plant (annual operating hours of 8000 hours), using figure 1 The high-temperature methanation reaction zone has two stages, and the reactors are filled with Ni-based catalysts (including Al 2 O 3 Carrier 60%, nickel 35%). Entrance of the primary reactor (H 2 -3CO) / CO 2 =4, the pressure is 3.5MPa, and the feed volume is 500,000 Nm 3 / h. The raw material synthesis gas 1 is divided into two parts, the ratio of the first-stage synthesis gas 2 and the second-stage synthesis gas 3 is 1:1.5, and the mixed stream 4 of the first-stage synthesis gas 2 and the circulating gas 8 enters the first-stage high temperature at a temperature of 300℃ Methanation reaction occurs in the methanation reactor 101, the volume ratio of the circulating gas 8 to the first-stage synthesis gas 2 is 2.4:1; the reaction outlet stream 5 has a temperature of 650°C, and is cooled by the first-stage high-temperature methanation reactor outlet coole...

Embodiment 2

[0033] One billion Nm 3 / Year synthesis gas to replace natural gas plant (annual operating hours of 8000 hours), using figure 1 The process technology of the first-level synthesis gas 2 and the recycle gas 8 is mixed, and the stream 4 enters the first-stage high-temperature methanation reactor 101 at a temperature of 320°C and a pressure of 4.5 MPa to undergo methanation reaction. The recycle gas 8 and the first-stage synthesis gas 2 The volume ratio is 2:1, the reaction outlet stream 5 has a temperature of 700°C, the secondary high temperature methanation reactor 102 has an inlet temperature of 320°C, an outlet temperature of 700°C, and a pressure of 4.2 MPa. Other conditions are the same as in [Example 1]. The volume ratio of material 7 to material 8 is 1.53, and the volume ratio of material 5 to material 3 is 1.65.

[0034] The volume content of each component of the natural gas product of the device is: CH 4 95%, H 2 0.8%, CO 2 2.5%, N 2 1.7%, the high temperature methanat...

Embodiment 3

[0037] One billion Nm 3 / Year synthesis gas to replace natural gas plant (annual operating hours of 8000 hours), using figure 1 The process technology of the raw material synthesis gas 1 has a pressure of 5.0MPa, which is divided into two parts. The ratio of the first-stage synthesis gas 2 and the second-stage synthesis gas 3 is 1:1, and the volume ratio of the circulating gas 8 and the first-stage synthesis gas 2 is 2: 1. The mixed stream 4 of the first-stage synthesis gas 2 and the recycle gas 8 enters the first-stage high-temperature methanation reactor 101 at a temperature of 290°C to undergo methanation reaction, and the reaction outlet stream 5 has a temperature of 640°C and undergoes a first-stage high-temperature methanation reaction. After cooling by the cooler 105 at the outlet of the reactor, the material 6 mixed with the secondary synthesis gas 3 enters the secondary high-temperature methanation reactor 102 at 300°C. The temperature of the reaction outlet stream 7 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com