Control device used for coal dry distillation process and control method thereof

A control device and process technology, applied in the direction of non-electric variable control, control/regulation system, and simultaneous control of multiple variables, etc., can solve problems such as insufficient gas combustion, environmental pollution, and unreasonable heat carrier temperature control methods. Achieve rapid adaptation to temperature changes, improve product quality, and solve the effects of mutual influence between dry distillation and drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

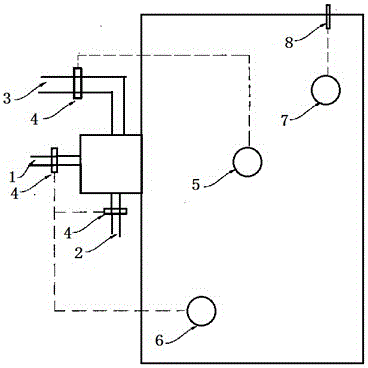

[0039] as attached figure 1 Shown: the present invention is a specific embodiment of a control device for coal dry distillation process. In the mixing chamber of the carbonization furnace, a mixing chamber temperature sensor 5 is arranged, which is connected to the logic proportional solenoid valve 4 arranged on the circulating gas pipeline 3 near the gas outlet; The sensor 6 is respectively connected to the logic proportional solenoid valve 4 arranged at the gas pipeline 1 and the air pipeline 2 close to the gas outlet, the pressure sensor 7 in the pipeline 3 of the circulating gas and the safety valve arranged at the top of the mixing chamber. valve 8. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com