Method for continuously separating and purifying high-purity oleamide

A technology of oleic acid amide and purification method, which is applied in the separation/purification of carboxylic acid amide, organic chemistry, etc., and can solve the problems of difficulty in realizing continuous, automatic, large-scale and stable production, affecting product color, and low product yield, so as to achieve improvement The effect of application value and market competitiveness, novel and reasonable process method, and high melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

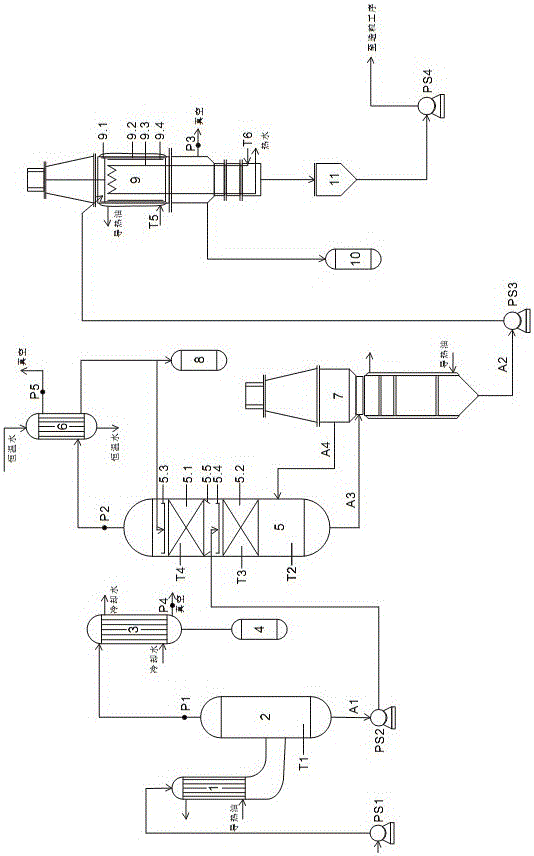

[0018] After the vacuum of the system at all levels is stable and meets the requirements, the crude oleic acid amide that has been melted and preheated at 90-100°C is sent to the falling film heater 1 (WK-6.0) by the delivery pump PS1, and is adjusted by the falling film heater 1 The heating temperature of the heat transfer oil is to control the temperature T1 of the bottom material of the flash tower 2 (WK-800) at 150-175°C, the vacuum degree P1 at the top of the flash tower 2 is controlled within 500 Pa, and the flow rate is 320-360L / h ( (digital display), the liquid level is controlled between 1 / 3-3 / 4, the dissolved gas (ammonia), moisture and volatile matter are evaporated, and the evaporated condensables are cooled by the cooler 3 and flow into accept slot 4;

[0019] The flash material A1 that has not been evaporated is sent to the distributor 5-4 of the rectification section of the fractionation tower 5 (φ800*10*13560) through the primary delivery pump PS2, and the flas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com