Energy-saving environmentally-friendly boiler

An energy-saving and environmental-friendly boiler technology, applied in the field of boilers, can solve the problems of poor overall effect of energy-saving and environmental protection, poor combustion effect of boilers, etc., and achieve good combustion effect, strong fire and full combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

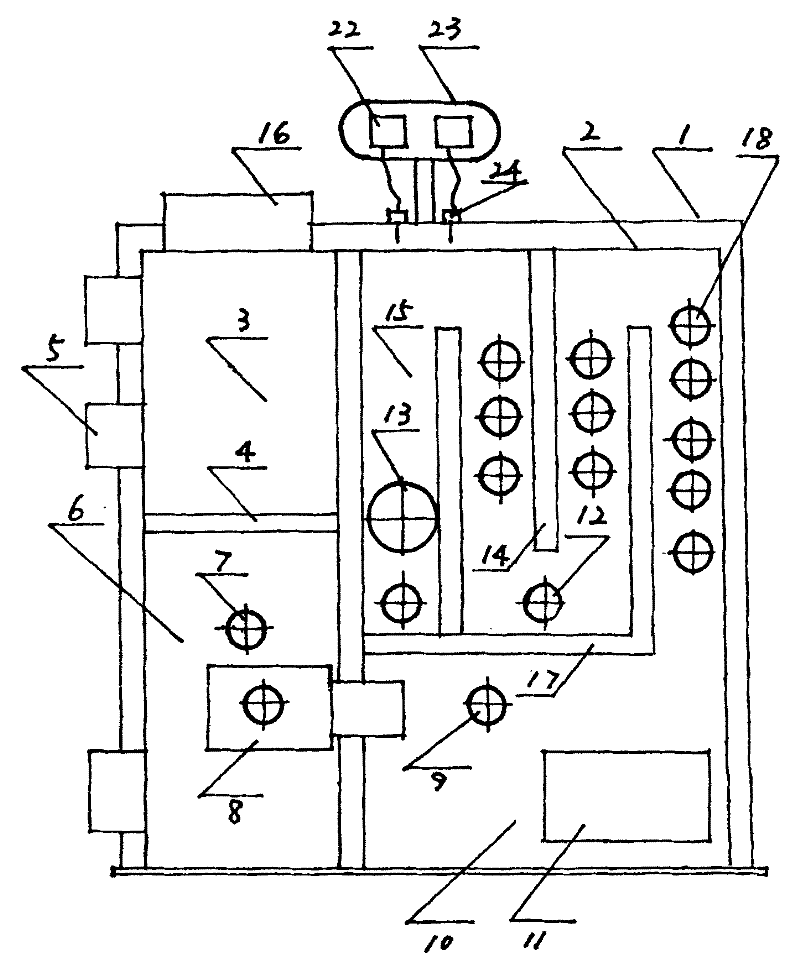

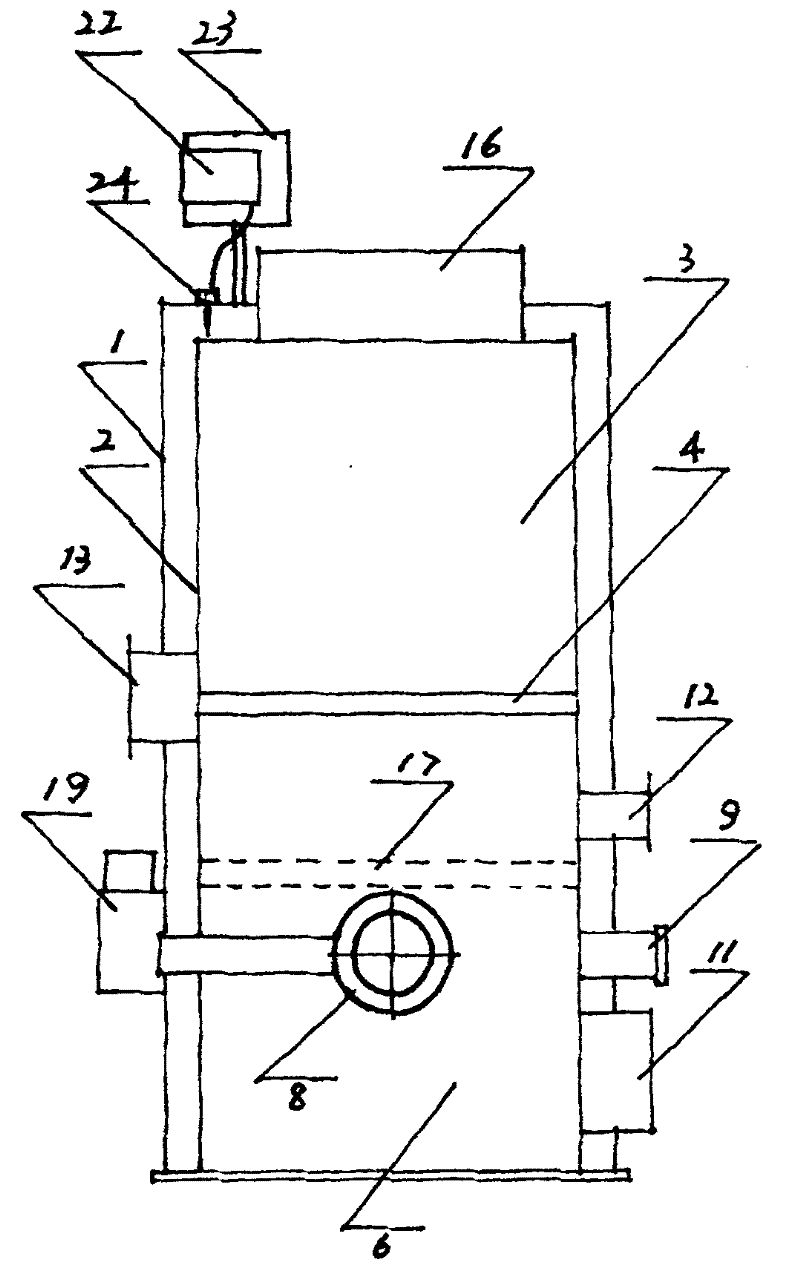

[0020] Such as Figure 1-2 As shown, the energy-saving and environmentally friendly boiler in this embodiment is suitable for biofuels, mainly including: furnace body 1, furnace 2, combustion chamber 3, fire grate 4, furnace door 5, gasification chamber 6, observation hole 7, jet combustion device 8 , observation hole 9, gas combustion chamber 10, side furnace door 11, soot cleaning hole 12, induced draft fan outlet 13, interlayer partition 14, combustion process combustion chamber 15, feeding port 16, interlayer top plate 17, hot water tube bundle 18, suction and discharge Port 19, display instrument 22, instrument box 23, sensor 24, etc. Furnace body 1 is provided with furnace chamber 2, a water interlayer is formed between furnace body 1 and furnace chamber 2, and furnace chamber 2 is provided with combustion chamber 3 and gasification chamber 6. Gas combustion chamber 10 and process combustion chamber 15. The combustion chamber 3 and the gasification chamber 6 are arranged...

Embodiment 2

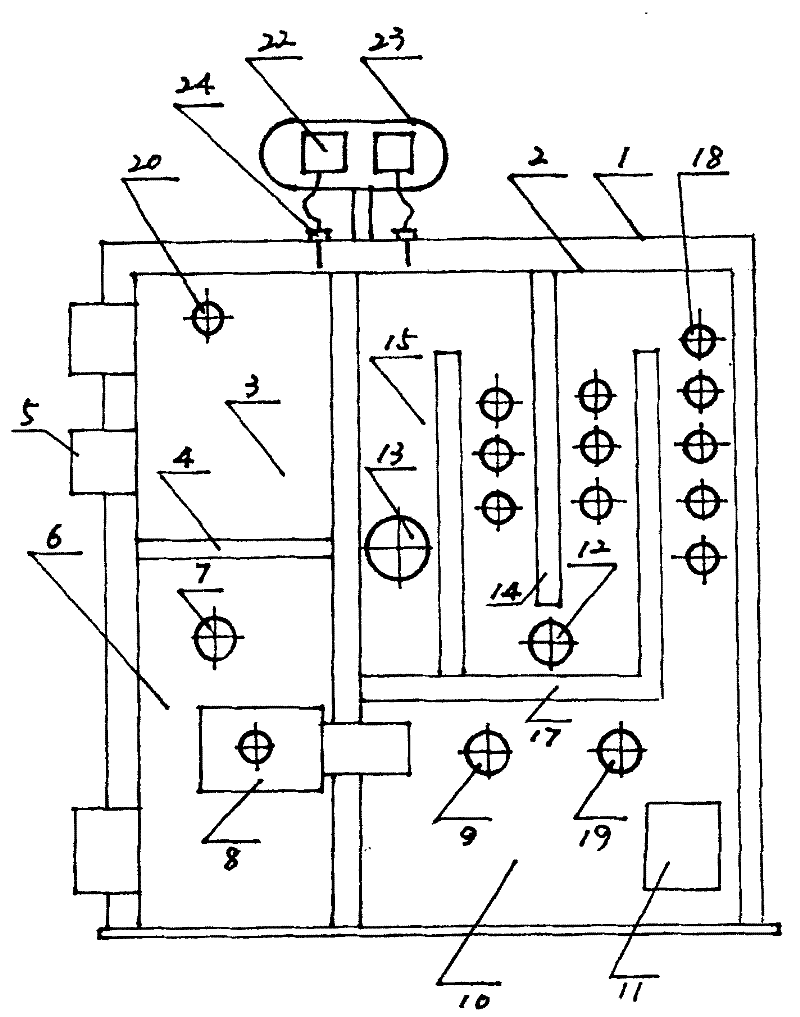

[0029] Such as Figure 3-4 As shown, the energy-saving and environment-friendly boiler in this embodiment is suitable for burning coal, and mainly includes: furnace body 1, furnace gall 2, combustion chamber 3, fire grate 4, furnace door 5, gasification chamber 6, observation hole 7, injection and suction hole type Oxygen supply and exhaust injection combustion device 8, observation hole 9, gas combustion chamber 10, side furnace door 11, soot cleaning hole 12, induced draft fan port 13, interlayer partition 14, process combustion chamber 15, interlayer top plate 17, hot water tube bundle 18. Suction and discharge port 19, air supply hole 20, air storage box 21, display instrument 22, instrument box 23, sensor 24, etc. Furnace body 1 is equipped with furnace 2, and a water interlayer is formed between furnace body 1 and furnace 2, and the furnace A combustion chamber 3 , a gasification chamber 6 , a gas combustion chamber 10 and a process combustion chamber 15 are arranged in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com