Method for preparing olefine from synthesis gas

A technology for producing olefins and synthesis gas, which is applied in the direction of producing hydrocarbons from carbon oxides, chemical instruments and methods, metal/metal oxides/metal hydroxide catalysts, etc. It can solve the problems of poor olefin selectivity and improve selectivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

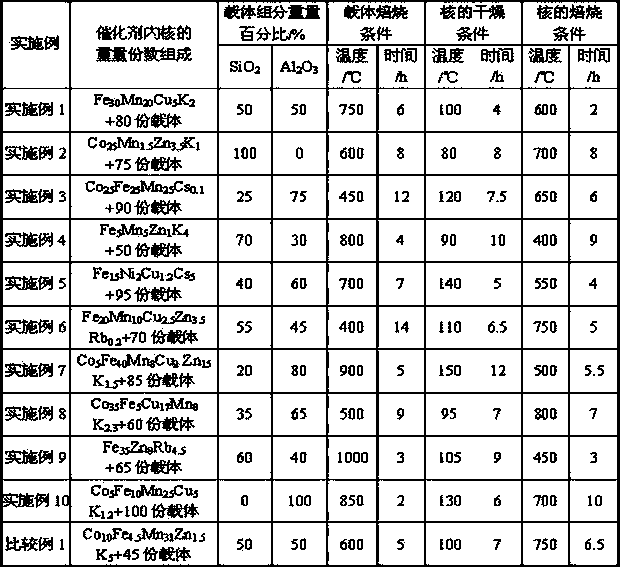

[0017] The silica sol containing 300 g of silicon dioxide was spray-molded and calcined at 750° C. for 6 hours to obtain carrier S, and the 15-150 μm portion was screened for use. Dissolve 187.5g of ferric nitrate hexahydrate, 65g of manganese nitrate, 19g of copper nitrate trihydrate and 5.17g of potassium nitrate in water to form a solution.

[0018] Weigh 80g of prepared SiO 2 Carrier, the above solution is impregnated onto the carrier by impregnation method, baked at 120°C for 6 hours, and then calcined at 600°C for 2 hours to obtain the catalyst core in parts by weight of 20 parts of Fe 30 mn 20 Cu 5 K 2 +80 parts of carrier, the subscript numbers are parts by weight.

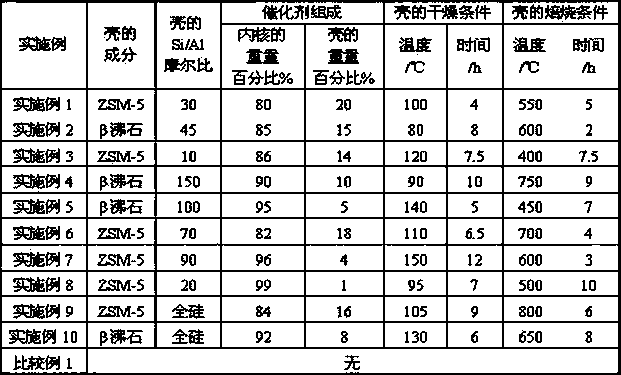

[0019] Spray-coat the slurry containing 20 grams of ZSM-5 molecular sieve with a Si / Al molar ratio of 30 onto the prepared catalyst core, dry at 100° C. for 4 hours, and roast at 550° C. for 2 hours to obtain the catalyst.

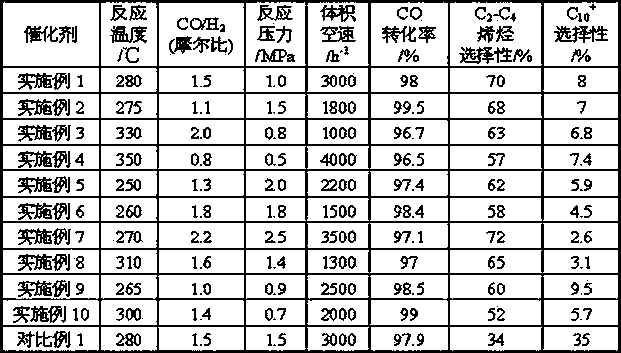

[0020] At a reaction temperature of 280°C and a reaction pressure of 1.0MPa, ...

Embodiment 2-10

[0023] The catalyst core composition, preparation method and preparation conditions are shown in Table 1, the composition and thickness of the shell layer are shown in Table 2, and the specific reaction conditions and results are shown in Table 3.

[0024]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com