Producing method of semiconductor device

A technology in the direction of semiconductor and cutting, applied in the direction of semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

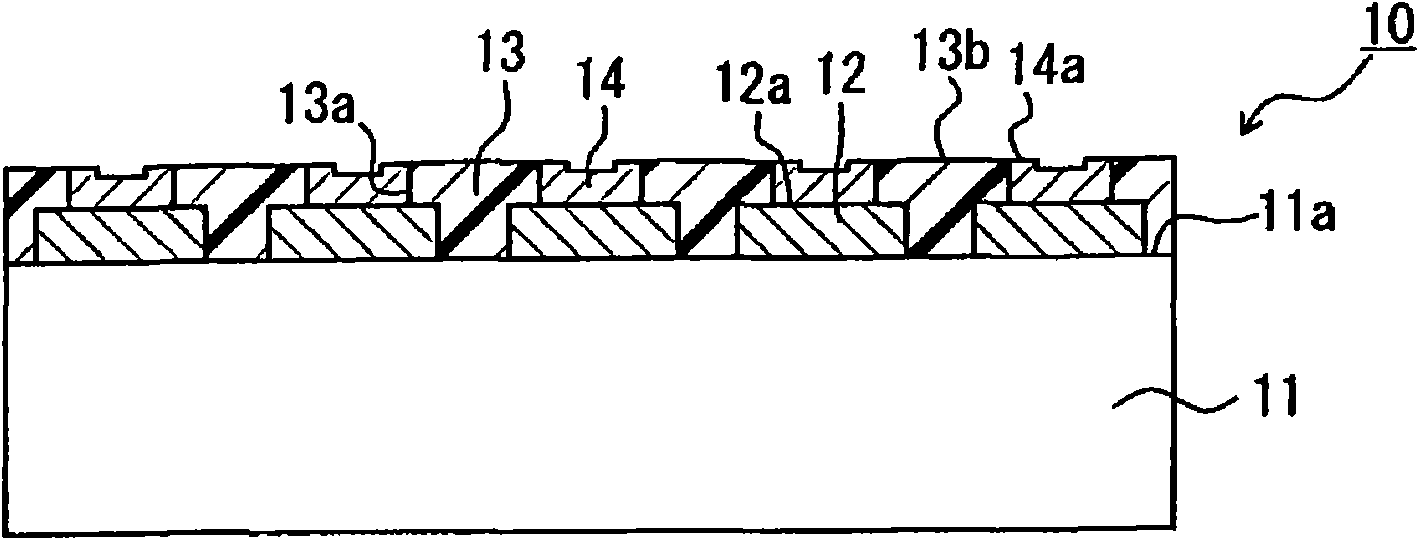

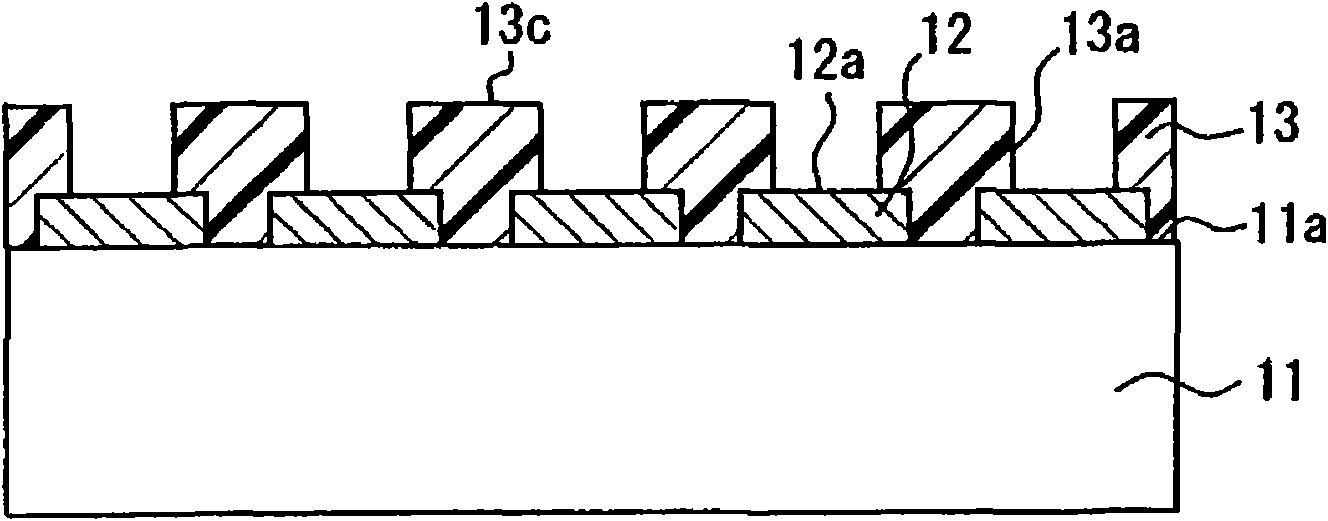

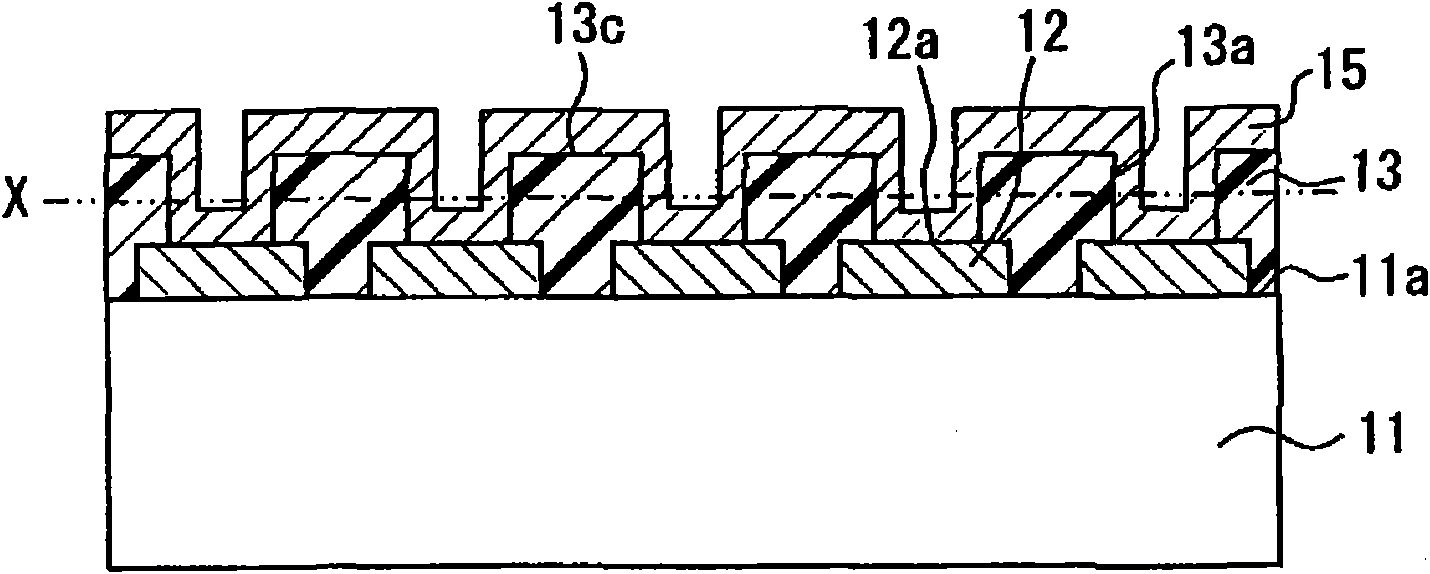

[0043] The following will refer to figure 1The structure of the semiconductor device 10 according to the first embodiment of the present invention is described. In addition, the following will refer to Figure 2A to Figure 2C A method of manufacturing the semiconductor device 10 is described. In each figure, a part of the semiconductor device 10 is enlarged and another part of the semiconductor device 10 is omitted for explanation. Figure 2B and Figure 2C The symbol X in indicates the cutting surface of the cutting tool. To make the location clear, the cutting surface X is also shown in Figure 2B middle.

[0044] In the manufacturing method of the semiconductor device 10 according to the present embodiment, (i) a part of the resin insulating layer having the surface on which the metal layer is arranged is cut in such a manner that within the resin insulating layer along the edge portion of the cutting tool and In the stress distribution of the peripheral portion of th...

no. 2 example

[0085] A method of manufacturing a semiconductor device according to a second embodiment of the present invention will be described below. In the manufacturing method according to the present embodiment, (v) a portion of the resin insulating layer 13 having the surface 13c exposed to the outside is cut by the cutting tool 30 in such a manner that along the edge of the cutting tool 30 in the resin insulating layer 13 In the stress distribution of the blade portion 30a and the peripheral portion of the blade portion 30a, the width at 90% of the maximum value is not more than 0.06 μm. To satisfy point (v), (vi) a resin insulating layer having an elongation of more than 0% and not more than 90% is used, (vii) a cutting tool whose edge portion has a radius of curvature of not more than 0.35 μm in the cutting direction is used use, and (vii) a portion of the resin insulating layer having the surface 13 c exposed to the outside is cut to a cutting thickness of not less than 0.5 μm an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com