Preparation method of taurine

A technology of taurine and sodium taurine, applied in the directions of sulfonate preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of complicated catalyst preparation, increase production cost, etc., and achieve the reaction time of aminolysis Shorter, higher conversion, higher yield per pass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

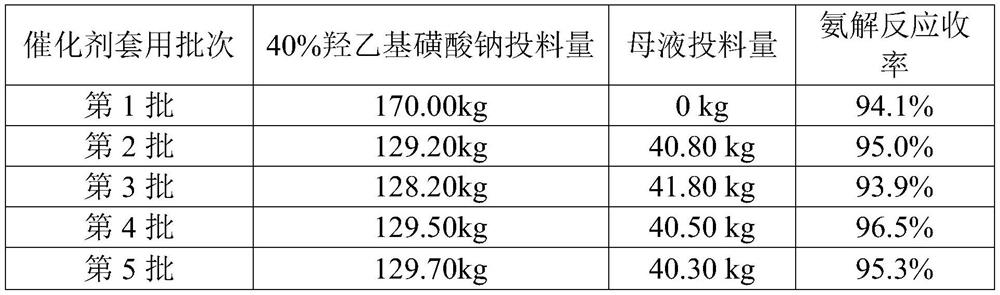

Examples

Embodiment 1

[0039] Pump 200kg of 25% ammonia water into the dissolution kettle, add 0.68kg of catalyst zinc particles, stir and dissolve. Add 40 kg of liquid ammonia and 170 kg of 40% sodium isethionate aqueous solution, and stir to obtain a mixture. After the mixture is pressurized to 8MPa by a high-pressure pump, it is first heated to 200°C by a heat conduction oil preheater, and then enters an ammonolysis reactor for reaction. The ammonolysis reaction temperature is 200°C, the pressure is 8 MPa, and the sodium taurate solution is obtained after 30 minutes of reaction. After removing ammonia and concentrating to remove water, 317.86 kg of sodium taurine aqueous solution was obtained. Sampling was carried out to detect the content of sodium taurine at 20.0%, and the yield of sodium taurine was calculated to be 94.10%.

[0040] 317.86kg sodium taurate aqueous solution forwardly passes through 159L weakly acidic 110 resin with 1.2BV / h flow velocity, when outlet feed liquid pH is close to...

Embodiment 2

[0043] Pump 250kg of 25% ammonia water into the dissolution tank, add 1.2kg of nickel acetate catalyst, and stir to dissolve. 30 kg of liquid ammonia and 200 kg of 35% sodium isethionate aqueous solution were introduced, and the mixture was uniformly stirred. After the mixture is pressurized to 6MPa by a high-pressure pump, it is first heated to 180°C by a heat transfer oil preheater. Enter the ammonolysis reactor to react, the ammonolysis reaction temperature is 180°C, the pressure is 6MPa, and the sodium taurate solution is obtained after the reaction for 45min. After removing ammonia and concentrating to remove water, 328.4 kg of sodium taurine aqueous solution was obtained. Sampling was carried out to detect the content of sodium taurine at 20.5%, and the yield of sodium taurine was calculated to be 96.8%.

[0044] 328.4kg sodium taurate aqueous solution forwardly passes through 192L weakly acidic 110 resin with 1.1BV / h flow rate, when outlet feed liquid pH is close to 8...

Embodiment 3

[0046] Pump 150kg of 25% ammonia water to the dissolution kettle, add 0.82kg of chromium trioxide catalyst, stir and dissolve. 40 kg of liquid ammonia and 100 kg of 35% sodium isethionate aqueous solution were introduced, and the mixture was uniformly stirred. After the mixture is pressurized to 10MPa by a high-pressure pump, it is first heated to 195°C by a heat transfer oil preheater. Enter the ammonolysis reactor to react, the ammonolysis reaction temperature is 195 ° C, the pressure is 10 MPa, and the sodium taurate solution is obtained after 30 minutes of reaction. After removing ammonia and concentrating to remove water, 169.3 kg of sodium taurine aqueous solution was obtained. Sampling was carried out to detect the content of sodium taurine at 19%, and the yield of sodium taurine was calculated to be 92.5%.

[0047] 169.3kg sodium taurate aqueous solution forwardly passes through 92L weakly acidic 110 resins with 0.9BV / h flow velocity, when outlet feed liquid pH is cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com