Modified foaming agent, microfoamed polypropylene material and preparation method

A polypropylene material and foaming agent technology, which is applied in the field of modified foaming agent, micro-foaming polypropylene material and its preparation, can solve the problems of not being able to meet environmental protection, restricting the use of AC foaming agent, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

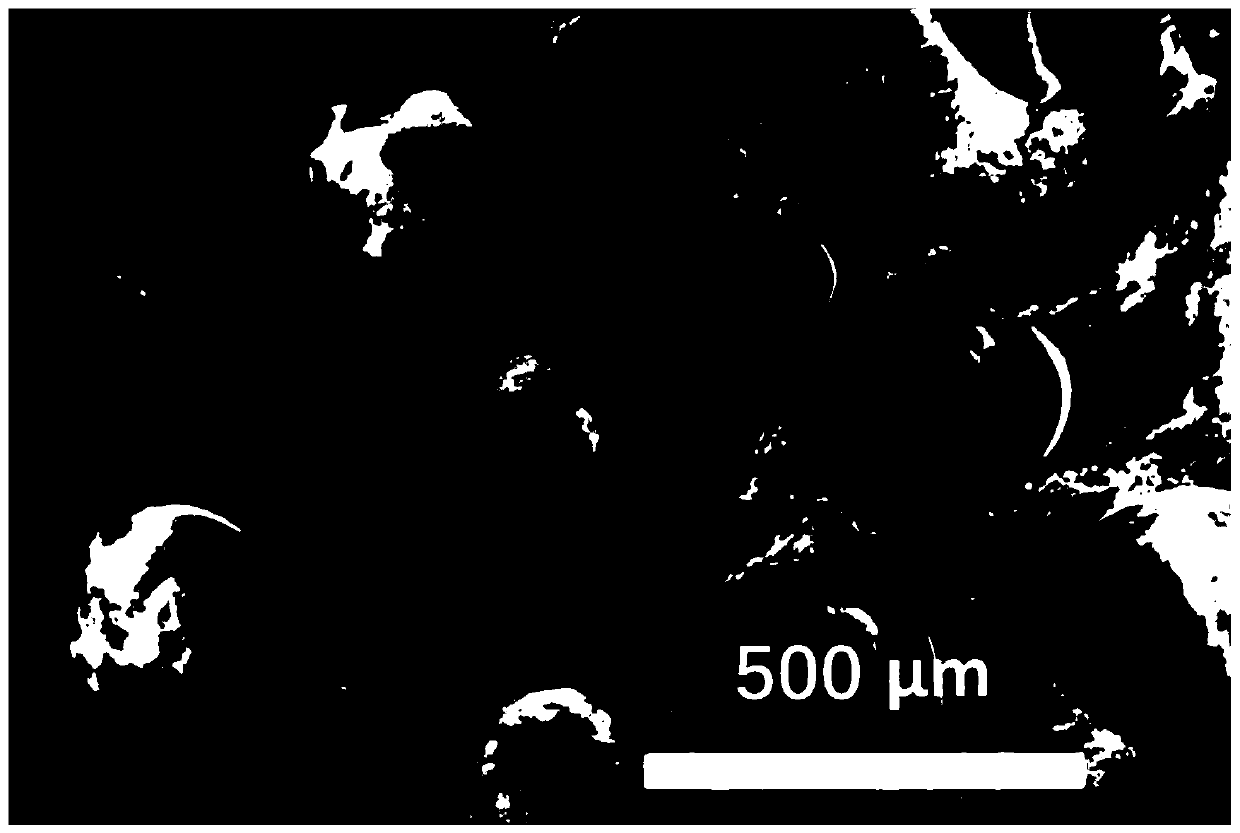

Image

Examples

preparation example Construction

[0023] In at least some embodiments of the present invention, the present invention provides a method for preparing a modified foaming agent, comprising: adding azodicarbonamide and aliphatic glycidyl ester into a flask at a molar ratio of 1:1.5 to 1:3 , the solvent is dimethylformamide or dimethyl sulfoxide, the solid content is 10-30%, placed in a water bath at 60°C, the reaction time is controlled for 1-3 hours, the solvent is removed and then dried to obtain the modified foaming agent. In at least some embodiments of the present invention, the obtained modified blowing agent has a decomposition temperature of 222°C-230°C, such as 224°C-227°C, and the ammonia content of the generated gas is less than 1%.

[0024] The modified foaming agent prepared by the above method can be used to prepare micro-foamed polypropylene material. The heat-resistant temperature of the prepared micro-foamed polypropylene material is high, and the modified foaming agent does not decompose during ...

Embodiment 1

[0027] Example 1 provides a method for preparing a modified blowing agent.

Embodiment 2

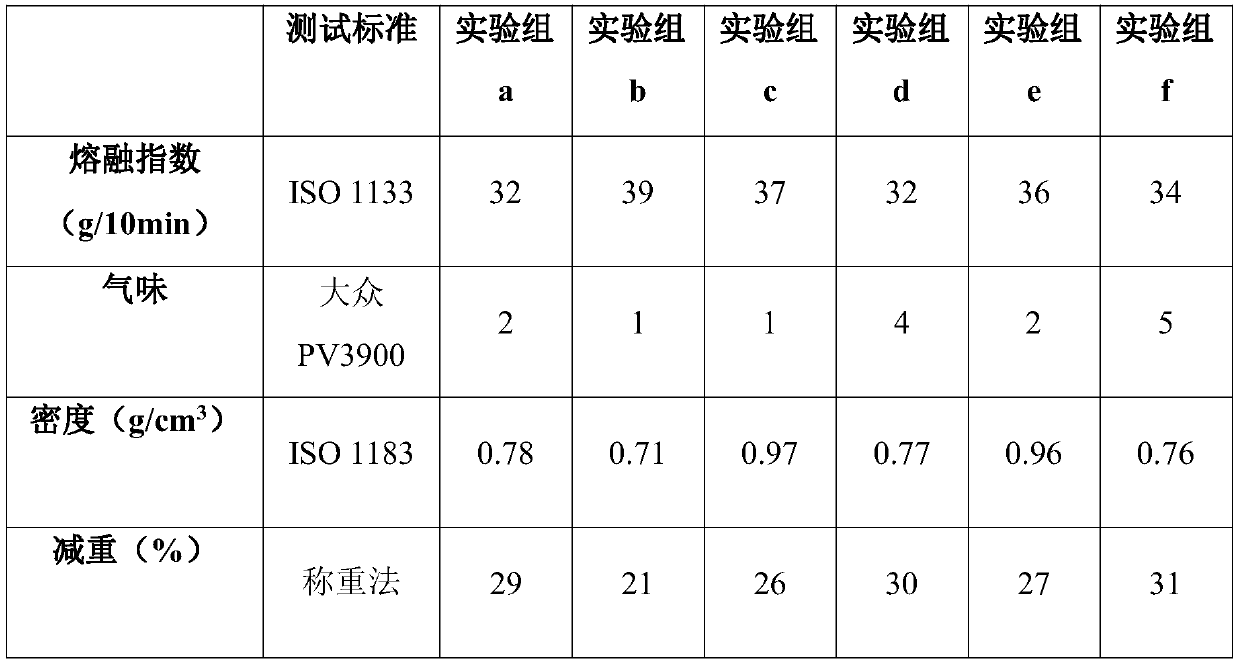

[0054] Example 2 provides the preparation method of micro-foamed polypropylene material.

[0055] Experimental group a

[0056] Experimental group a provides a kind of micro-foaming polypropylene material, and it comprises:

[0057] Polypropylene resin, the melt index of described polypropylene resin is 38g / 10min;

[0058] The modified foaming agent prepared by experimental group 1, the mass percentage of modified foaming agent and polypropylene resin is 1%;

[0059] Nucleating agent (3,4-dimethylbenzylidene sorbitol), the mass percentage of 3,4-dimethylbenzylidene sorbitol and polypropylene resin is 16%;

[0060] Antioxidant (DLTP), the mass percentage of DLTP and polypropylene resin is 0.2%;

[0061] Lubricant (calcium stearate), the mass percentage of calcium stearate and polypropylene resin is 0.8%.

[0062] The above microfoamed polypropylene material was prepared by the following method:

[0063] Add modified foaming agent, nucleating agent, antioxidant, lubricant t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com