Cellulose fermentable sugar, and preparation method and application of same

A technology for cellulose and sugar fermentation, applied in the field of fiber materials, can solve the problems of increasing bioethanol, low cellulase production, and low ethanol fermentation efficiency, and achieve low hemicellulose content, high concentration, and high polymerization small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

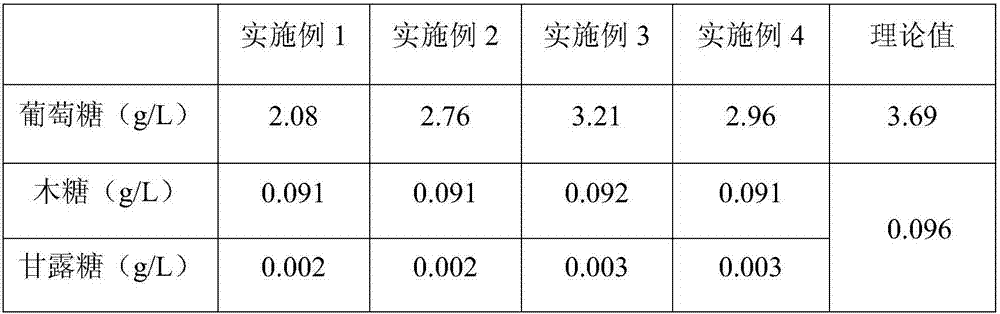

Examples

Embodiment 1

[0033] Example 1: Preparation of cellulosic fermentable sugars

[0034] (1) Take 7g of dry hemp pulp with known cellulose and hemicellulose contents of 95.33% and 1.73% respectively and mix them with sodium hydroxide and urea mixed solution at a mass ratio of 1:40, stir to form a uniform mixing system ; Wherein, the mass fractions of sodium hydroxide and urea in the mixed system are 5% and 3% respectively.

[0035] (2) Cool the mixed system to -8°C under sealed conditions (the system is completely sealed to avoid the reaction of carbon dioxide and sodium hydroxide in the air), and stir at 3000r / min for 5min to obtain a cellulose solution.

[0036] (3) Take the cellulose solution and adjust the pH to neutrality with a hydrochloric acid solution with a molar concentration of 6mol / L, then concentrate it to a concentration of 6g / L through a rotary evaporator, and then use a high-speed shear of 6000r / min Mix the concentrated cellulose solution with dilute sulfuric acid solution wi...

Embodiment 2

[0037] Example 2: Preparation of cellulosic fermentable sugars

[0038] (1) Take 7g of dry hemp pulp with known cellulose and hemicellulose content of 95.33% and 1.73% respectively, mix with sodium hydroxide and urea mixed solution at a mass ratio of 1:50, stir to form a uniform mixing system ; Wherein, the mass fractions of sodium hydroxide and urea in the mixed system are 7% and 7% respectively.

[0039] (2) Cool the mixed system to -9°C under sealed conditions (the system is completely sealed to avoid the reaction of carbon dioxide and sodium hydroxide in the air), and stir at 5000r / min for 7min to obtain a cellulose solution.

[0040] (3) Take the cellulose solution and adjust the pH to neutrality with a hydrochloric acid solution with a molar concentration of 6mol / L, then concentrate it to the concentration of the cellulose solution by a rotary evaporator to be 7g / L, and then use a high-speed shear of 8000r / min Mix the concentrated cellulose solution with dilute sulfuric...

Embodiment 3

[0041] Example 3: Preparation of cellulosic fermentable sugars

[0042] (1) Take 7g of dry hemp pulp with known cellulose and hemicellulose contents of 95.33% and 1.73% respectively, mix with sodium hydroxide and urea mixed solution at a mass ratio of 1:60, stir to form a uniform mixing system ; Wherein, the mass fractions of sodium hydroxide and urea in the mixed system are 9% and 11% respectively.

[0043] (2) Cool the mixed system to -10°C under sealed conditions (the system is completely sealed to avoid the reaction of carbon dioxide and sodium hydroxide in the air), and stir for 7 minutes under the condition of 8000r / min to obtain a cellulose solution.

[0044] (3) Take the cellulose solution and adjust the pH to neutral with a hydrochloric acid solution with a molar concentration of 8mol / L, then concentrate it to the concentration of the cellulose solution by a rotary evaporator to be 8g / L, and then use a high-speed shear of 9000r / min Mix the concentrated cellulose solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com