Olefin polymerization catalyst ingredient, preparation method and use of the olefin polymerization catalyst ingredient, catalyst system, use of the catalyst system, and olefin polymerization method

A technology of olefin polymerization and catalyst, applied in the field of catalyst components for olefin polymerization and its preparation and application, catalyst system and application, and olefin polymerization, which can solve the problems of low catalytic activity and achieve high polymerization activity and high yield , the effect of excellent dynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] According to the preparation method of the catalyst component for olefin polymerization provided by the present invention, the method may comprise the following steps:

[0036] (1) carrying out the first contact reaction with magnesium halide and alcohol compound in the presence of hydrocarbon solvent to form a homogeneous solution;

[0037] (2) In the presence of a precipitation aid, the homogeneous solution obtained in step (1) is subjected to a second contact reaction with a titanium compound to precipitate a solid precipitate to obtain a mixture containing a solid precipitate;

[0038] (3) carrying out the third contact reaction with the mixture obtained in step (2) and the internal electron donor compound to obtain a suspension;

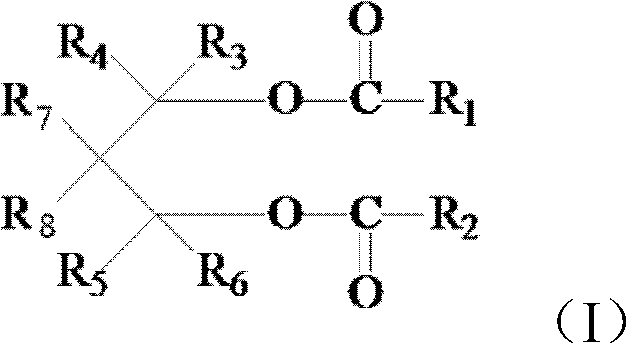

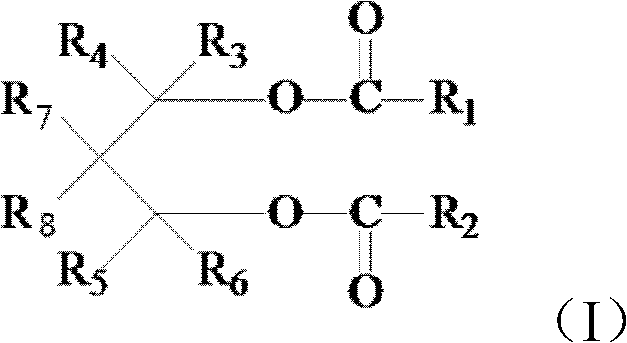

[0039] Wherein, the precipitation aid includes a precipitation aid a, a precipitation aid b, a precipitation aid c and a precipitation aid d, and the precipitation aid a is a glycol ester compound shown in formula (I),

[0040]

[004...

Embodiment 1

[0109] (1) Preparation of catalyst components

[0110] In the reaction kettle that has been repeatedly replaced by high-purity nitrogen, 52.5mmol (5.0g) of anhydrous magnesium chloride, 328mmol (35ml) of toluene, and 140mmol (22ml) of 2-ethylhexanol were added in sequence, at a stirring speed of 450rpm and a temperature of 110°C Under the conditions of the reaction for 3.0 hours, a stable and uniform alcoholate solution was obtained; then 0.8mmol (0.4ml) of 3,5-heptanediol dibenzoate was added, and 2-isopropyl-2-(3-methyl butyl)-1,3-dimethoxypropane 0.6mmol (0.3ml), diisobutyl phthalate 5.6mmol (1.5ml), tetrabutyl titanate 2.2mmol (0.75ml), stirred for 60 minutes, cool to room temperature.

[0111] Add the above-mentioned 3,5-heptanediol dibenzoate 0.8mmol (0.4ml), 2-isopropyl-2-(3-methylbutyl)-1,3-dimethoxypropane 0.6 mmol (0.3ml), diisobutyl phthalate 5.6mmol (1.5ml), tetrabutyl titanate 2.2mmol (0.75ml) homogeneous alcoholate solution was added to the fully replaced nitro...

Embodiment 2

[0123] Add 0.8mmol (0.4ml) of 3,5-heptanediol dibenzoate to Example 1, 2-isopropyl-2-(3-methylbutyl)-1,3-dimethoxy Propane 0.6mmol (0.3ml), diisobutyl phthalate 5.6mmol (1.5ml), tetrabutyl titanate 2.2mmol (0.75ml), add 4-ethyl-3,5-heptanediol instead Dibenzoate 2.6mmol, 2-isopropyl-2-(3-methylbutyl)-1,3-dimethoxypropane 6mmol, di-n-butyl phthalate 10.5mmol, iso-titanate Propyl ester 4.4mmol, all the other are with embodiment 1. The results of the titanium content of the catalyst component, the content of the precipitation aid a and the particle size distribution of the catalyst component are shown in Table 1.

[0124] Catalyst Components The polymerization activity of the prepared catalyst system in propylene polymerization and the performance parameters of the propylene polymer are shown in Table 2. Catalyst Components The polymerization activity of the catalyst system prepared in the butene polymerization and the performance parameters of the butene polymer are shown in T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com