Hydrogenation method for residual oil

A technology of residual oil and hydrogenation reaction, which is applied in the field of hydrogenation of residual oil, can solve the problems of long operating cycle, low catalyst utilization rate, and short operating cycle, etc., to extend the operating cycle, increase operating efficiency, and improve Economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

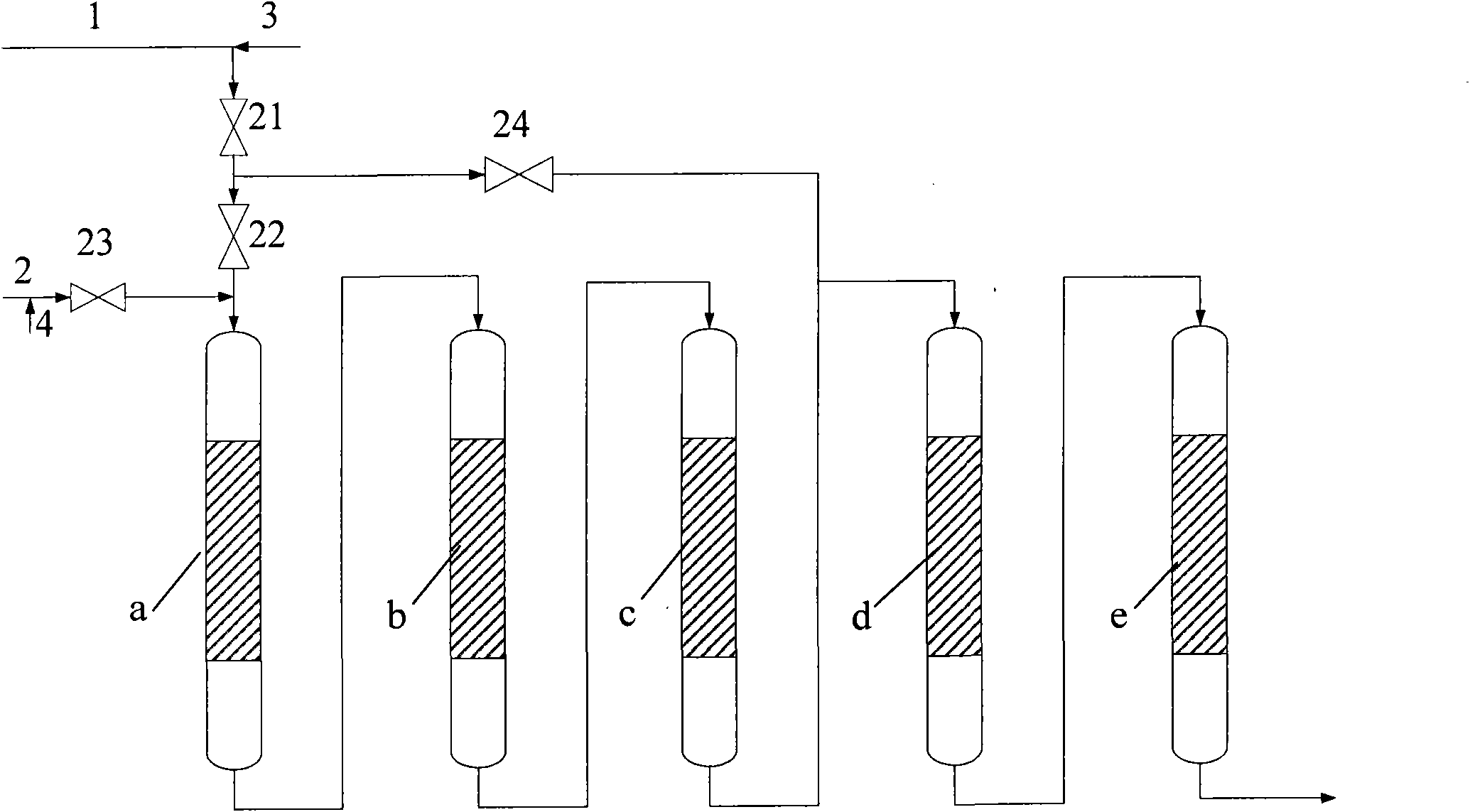

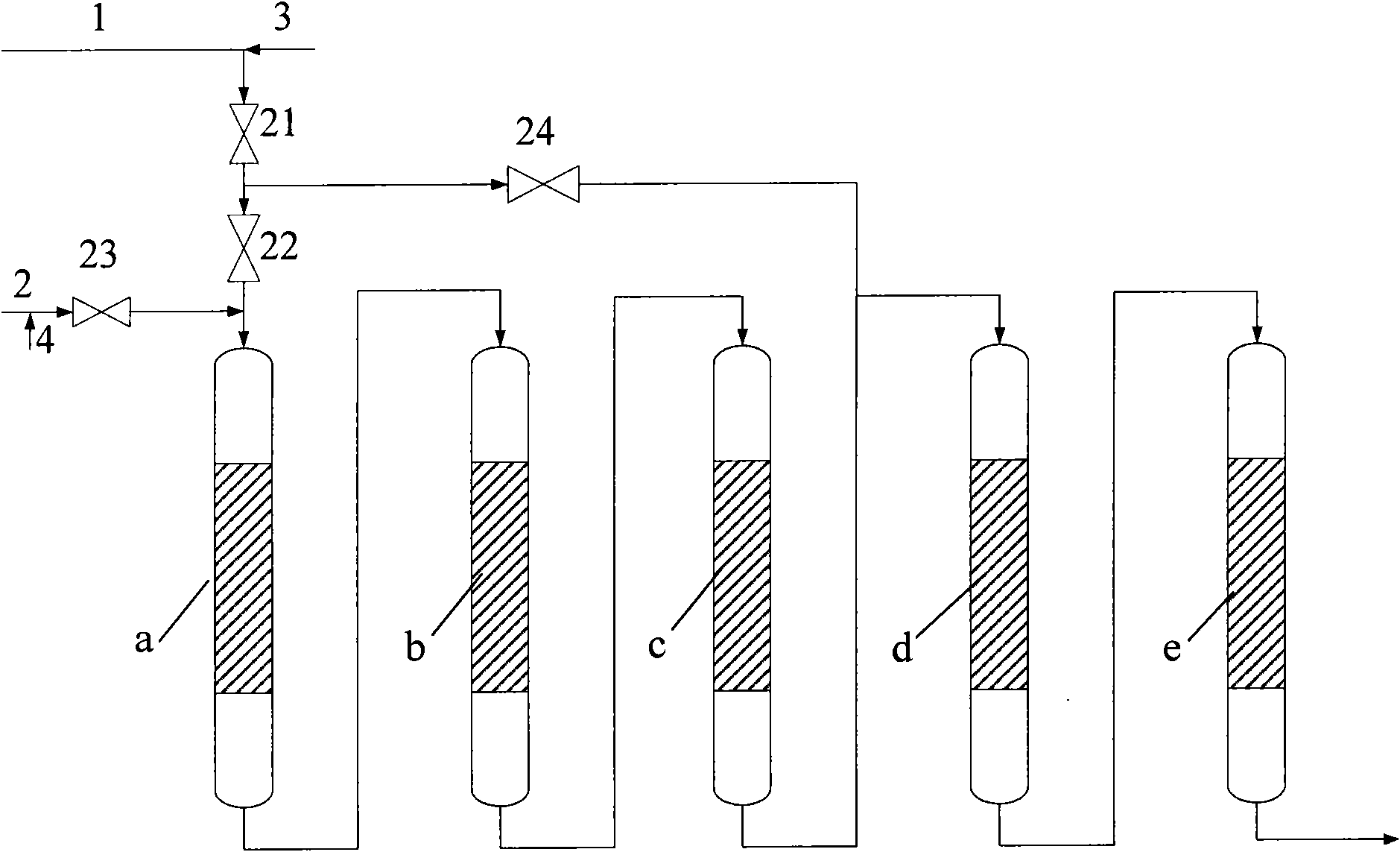

[0042] like figure 1 As shown, the device of the present invention is a self-designed fixed-bed hydroprocessing test device, which adopts five reactors with a volume of 5 liters in series and a top-down process flow for raw oil. The first hydrogenation reaction zone includes Three reactors are a reactor, b reactor and c reactor. The second hydrogenation reaction zone includes two reactors, namely d reactor and e reactor. A feeding line connected to the residue raw material pipeline 1 is arranged at the feed port. The designed maximum pressure drop of each reactor is 1.0MPa.

[0043] The catalysts used are a full series of residual oil hydrotreating catalysts developed by the Research Institute of Petrochemical Sciences, among which, RG, RDM and RMS series heavy and residual oil hydrogenation protection catalysts, hydrodemetallization catalysts and hydrodesulfurization catalysts are composed of catalysts Produced by Changling Branch.

[0044] The loading situation of catalys...

Embodiment 2

[0057] The same fixed-bed hydrotreating test device as in Example 1 was used.

[0058] The catalysts and loading conditions adopted in the first four reactors are the same as in Example 1, and the hydrodesulfurization catalyst RMS-1 and the hydrodenitrogenation catalyst RSN are filled from top to bottom in the e reactor of the second hydrogenation reaction zone -1, the filling ratio is 85:15.

[0059] The process of hydrogenation reaction of residual oil is as follows: when the reaction pressure is 15.0MPa, the reaction temperature is 385°C, the hydrogen-oil ratio is 1000 (v / v), and the liquid hourly volume space velocity of the raw material is 0.3h -1 Under the operating conditions of , the light sandy normal slag raw material from pipeline 1 as residual oil raw material is mixed with hydrogen gas from pipeline 3 and enters reactor a through open valves 21 and 22, and then enters reactor b, c, d and e in sequence The main properties of the light sand and normal slag raw mate...

Embodiment 3

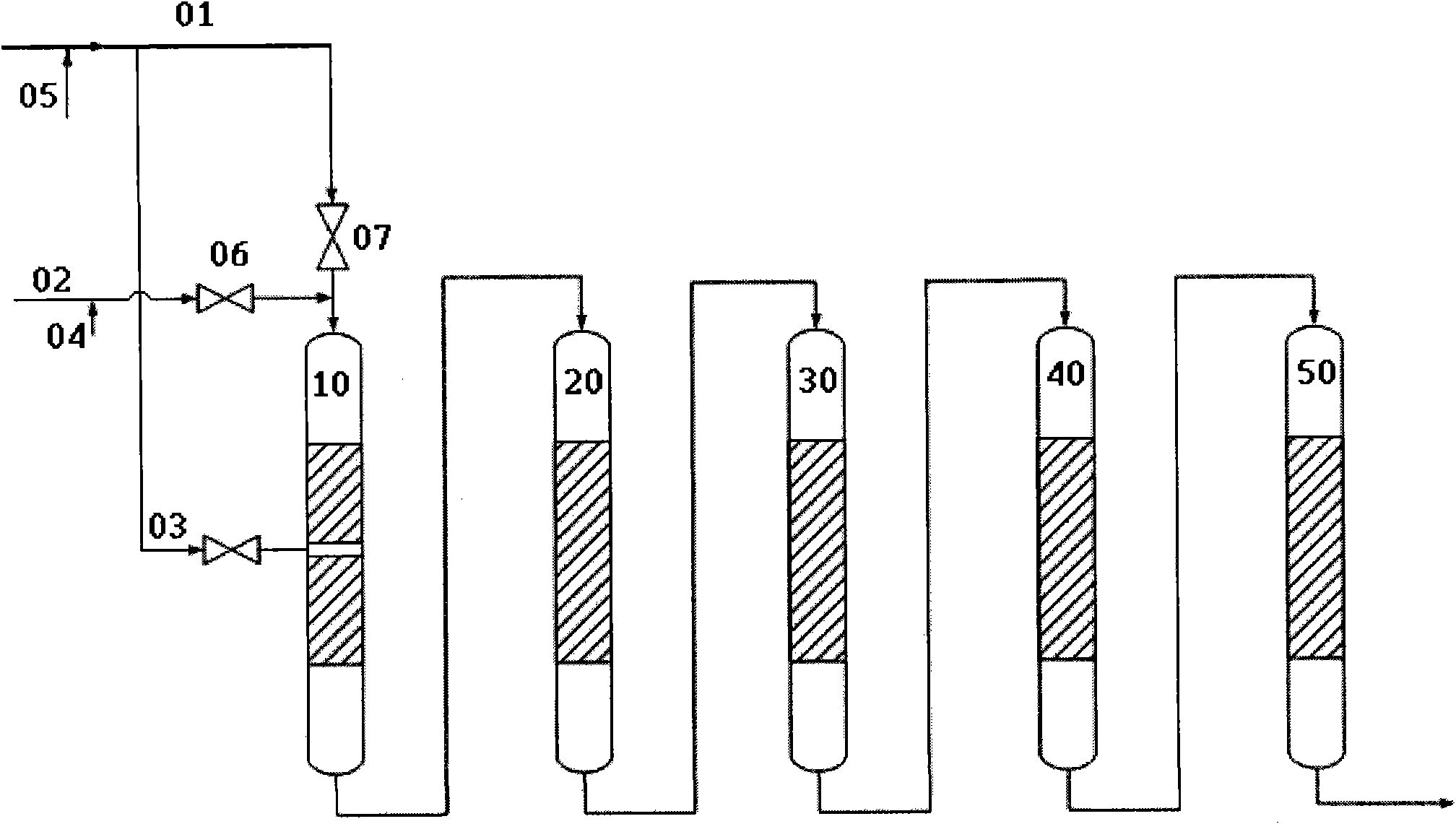

[0066] The same as in Example 1, using a self-designed fixed-bed hydroprocessing test device, the difference is that the device uses four reactors with a volume of 5 liters in series, and the first hydrogenation reaction zone includes two reactors, namely a reaction reactor and reactor b, the second hydrogenation reaction zone includes two reactors, reactor d and reactor e, and a feed line connected to the residual oil raw material pipeline is set at the feed port of reactor e.

[0067] The catalysts used in reactor a, reactor b and reactor d are the same as those in Example 1, and reactor e is filled with hydrodesulfurization catalyst RMS-1 and hydrodesulfurization catalyst RSC-1. Among them, the hydrogenation carbon removal catalyst RSC-1 was developed by the Petrochemical Science Research Institute and produced by Catalyst Changling Branch.

[0068] The loading situation of catalyst in each reactor is:

[0069] In the first hydrogenation reaction zone, the catalysts in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com