Lubricating grease and preparation method thereof

A technology of lubricating grease and lubricating base oil, which is applied in the field of lubricating grease, can solve the problems such as insufficient drop point and difficult to obtain raw materials, and achieve good extreme pressure and anti-wear performance, ball bearing lubrication life, and excellent colloidal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

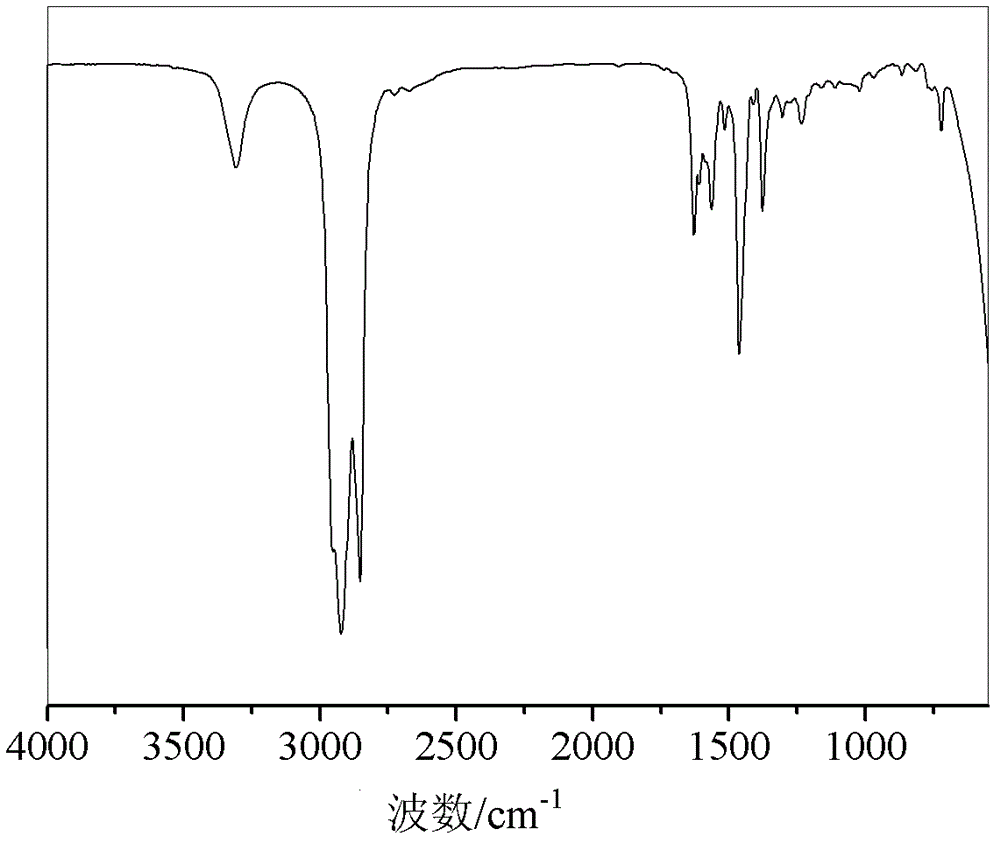

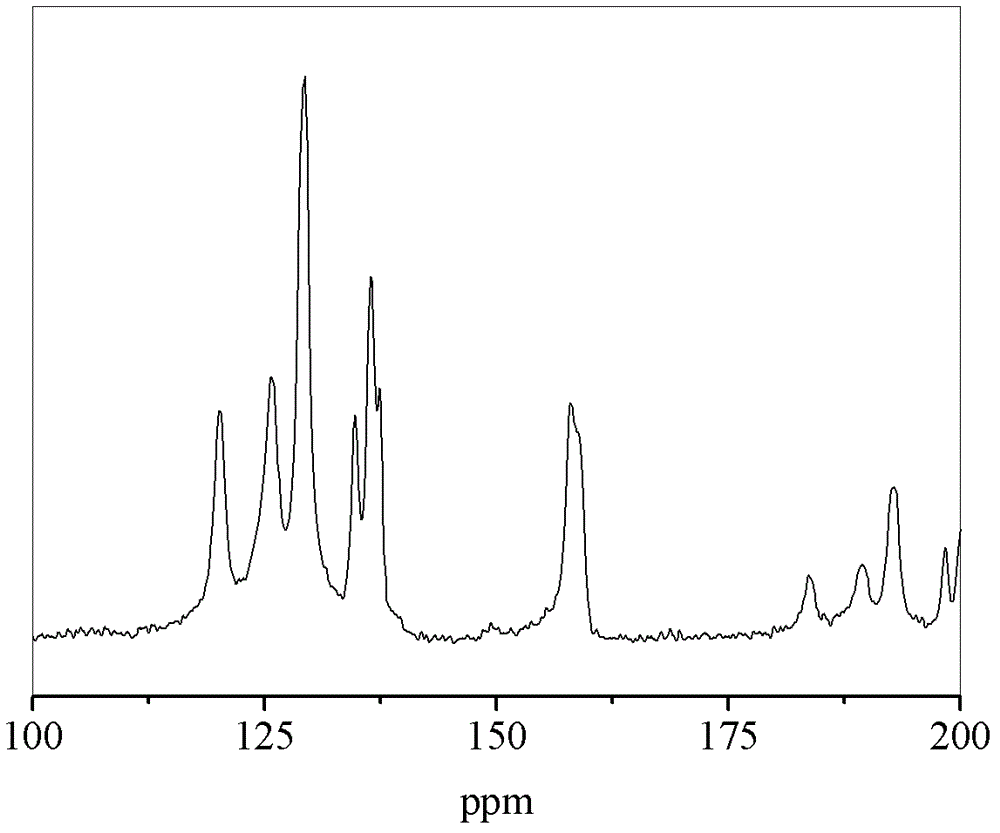

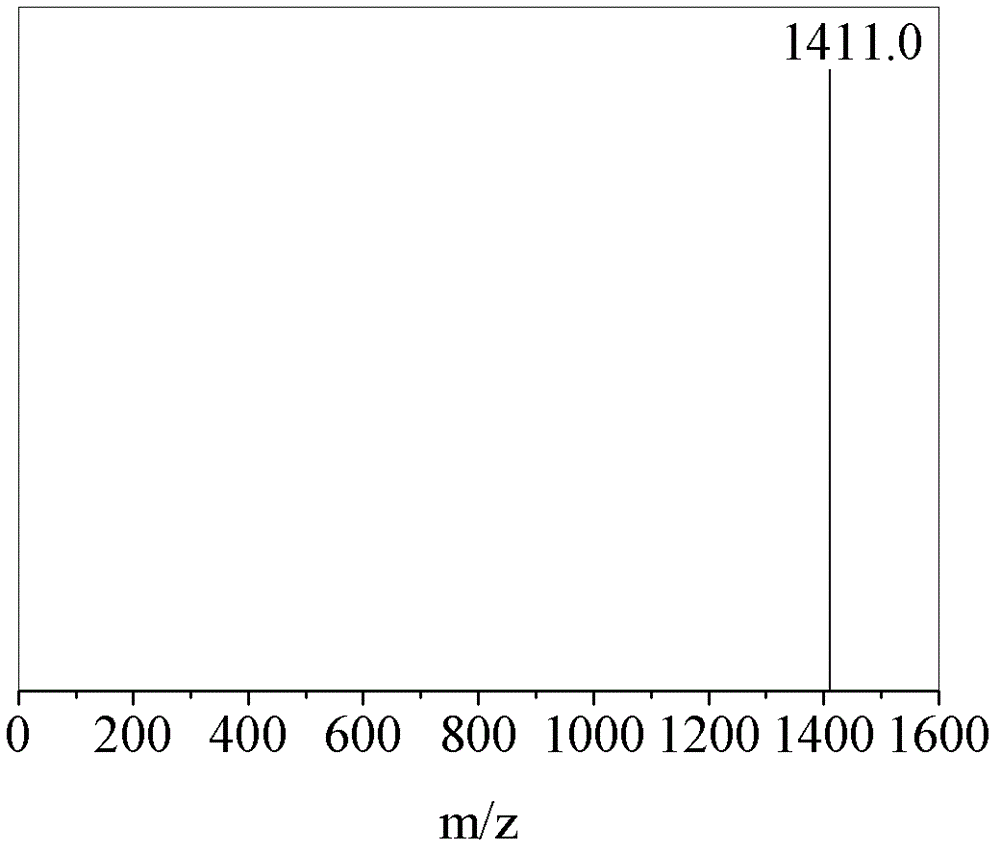

[0034] The present invention also provides a method for preparing lubricating grease, the method comprising: first contacting alkoxy zirconium, higher fatty acid and aromatic acid in lubricating base oil in reaction kettle A at 60-120°C reaction; then, at 85-100°C, the mixture obtained after the first contact reaction is subjected to a second contact reaction with water, and the product obtained after the second contact reaction is subjected to temperature rise and dehydration; and then Step (1) or (2) below:

[0035] (1) Mix the product of reactor A with diisocyanate, then react the obtained mixture with monoamine, diamine and diisocyanate in sequence, and heat the obtained mixture to 200-220°C for refining;

[0036] (2) The diisocyanate dissolved in the lubricating base oil is reacted with monoamine, diamine and diisocyanate in turn in reactor B, then the reaction mixture is combined with the product of reactor A, and the resulting mixture is heated Refining at 200-220°C; ...

Embodiment 1

[0062] This example is used to illustrate the grease of the present invention and its preparation method.

[0063]Raw material components: zirconium isopropoxide isopropanol complex (9.33kg); 12-hydroxystearic acid (4.80kg); phthalic acid (2.60kg); octadecylamine (0.84kg); ethylenediamine (0.19 kg); 4,4'-diphenylmethane diisocyanate (MDI, 1.17 kg); HVI500SN base oil (40 kg).

[0064] Add 9.33kg isopropoxide zirconium isopropanol complex (purchased from Sigma-Aldrich company) and 9kg of HVI500SN base oil (100 ℃ Kinematic viscosity is 11mm 2 / s, purchased from ExxonMobil Chemical Company), stirred, heated to 80°C, added 4.80kg of 12-hydroxystearic acid (purchased from Tongliao Weining Chemical Co., Ltd.), and reacted at constant temperature for 20 minutes; 2.60kg of phthalic acid, heat up to 105°C, react for 30 minutes, add 6kg of HVI500SN base oil, cool down to 95°C, add 1kg of water, and react at constant temperature for 20 minutes; heat up to 110°C under stirring for dehydr...

Embodiment 2

[0074] This example is used to illustrate the grease of the present invention and its preparation method.

[0075] Raw material components: zirconium ethylate (6.72kg); stearic acid (4.55kg); terephthalic acid (2.66kg); octadecylamine (0.84kg); ethylenediamine (0.19kg); MDI (1.17kg); Poly-α-olefin synthetic oil PAO10 (110kg).

[0076] Add 6.72kg of zirconium ethylate (purchased from Sigma-Aldrich company) and 20kg of polyalpha-olefin synthetic oil PAO10 (100 ℃ kinematic viscosity is 10mm 2 / s, purchased from ExxonMobil Chemical Company), stirred, heated to 80°C, added 4.55kg of stearic acid, and reacted at constant temperature for 60 minutes; added 2.66kg of terephthalic acid, heated to 105°C and reacted for 30 minutes, Add 20kg of poly-α-olefin synthetic oil PAO 10, cool down to 95°C, add 1kg of water, and react at constant temperature for 20 minutes; heat up to 110°C under stirring for dehydration, after dehydration, cool down to 90°C, add 0.78kg of MDI , and continued to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com