Method for aromatizing light hydrocarbons

An aromatization, light hydrocarbon technology, applied in chemical instruments and methods, organic chemistry, hydrocarbons, etc., can solve the problems of difficult reaction, low utilization rate of light hydrocarbons, less than 20% of the total utilization rate, etc. Abrasion ability, effect of high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

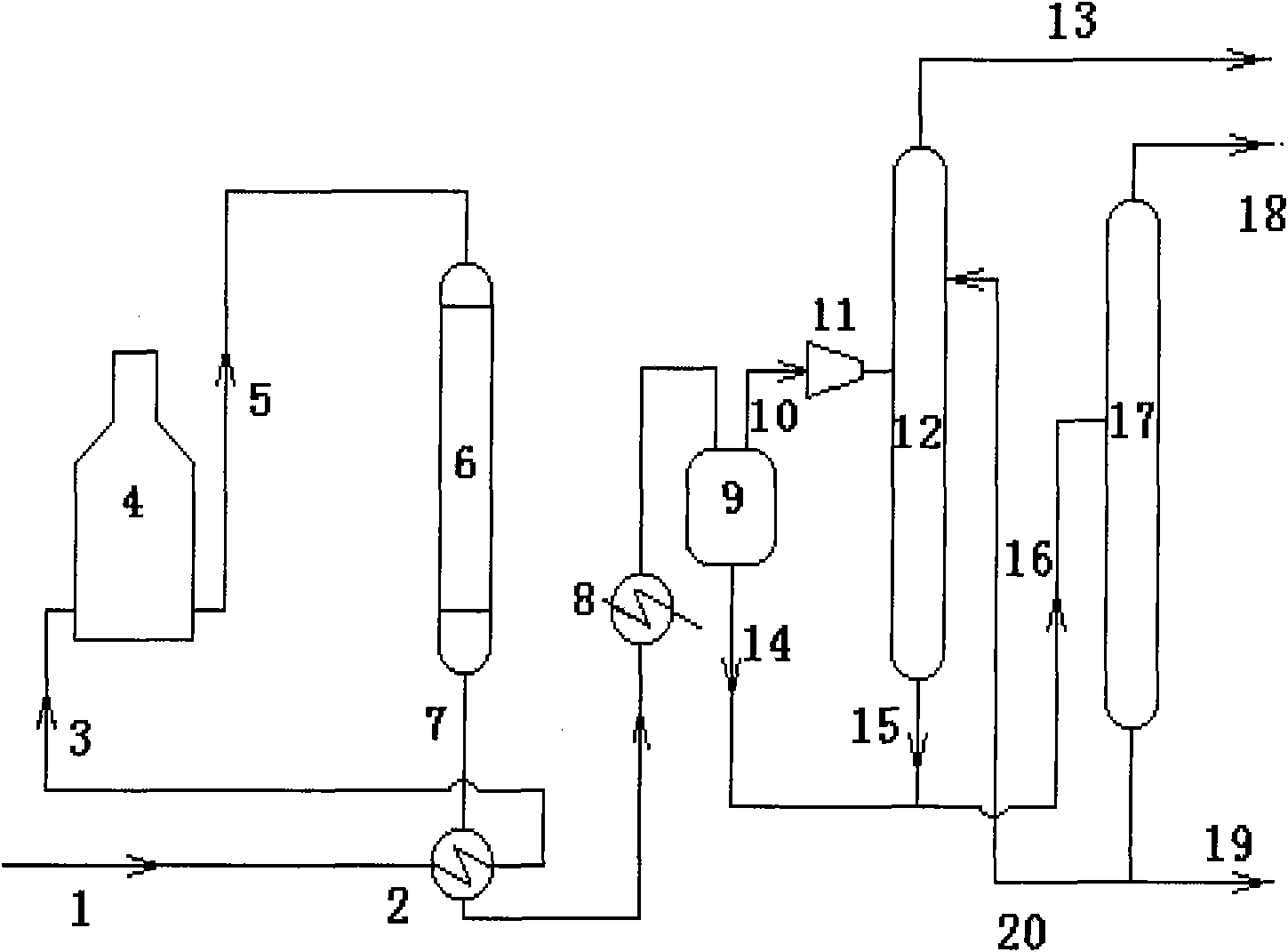

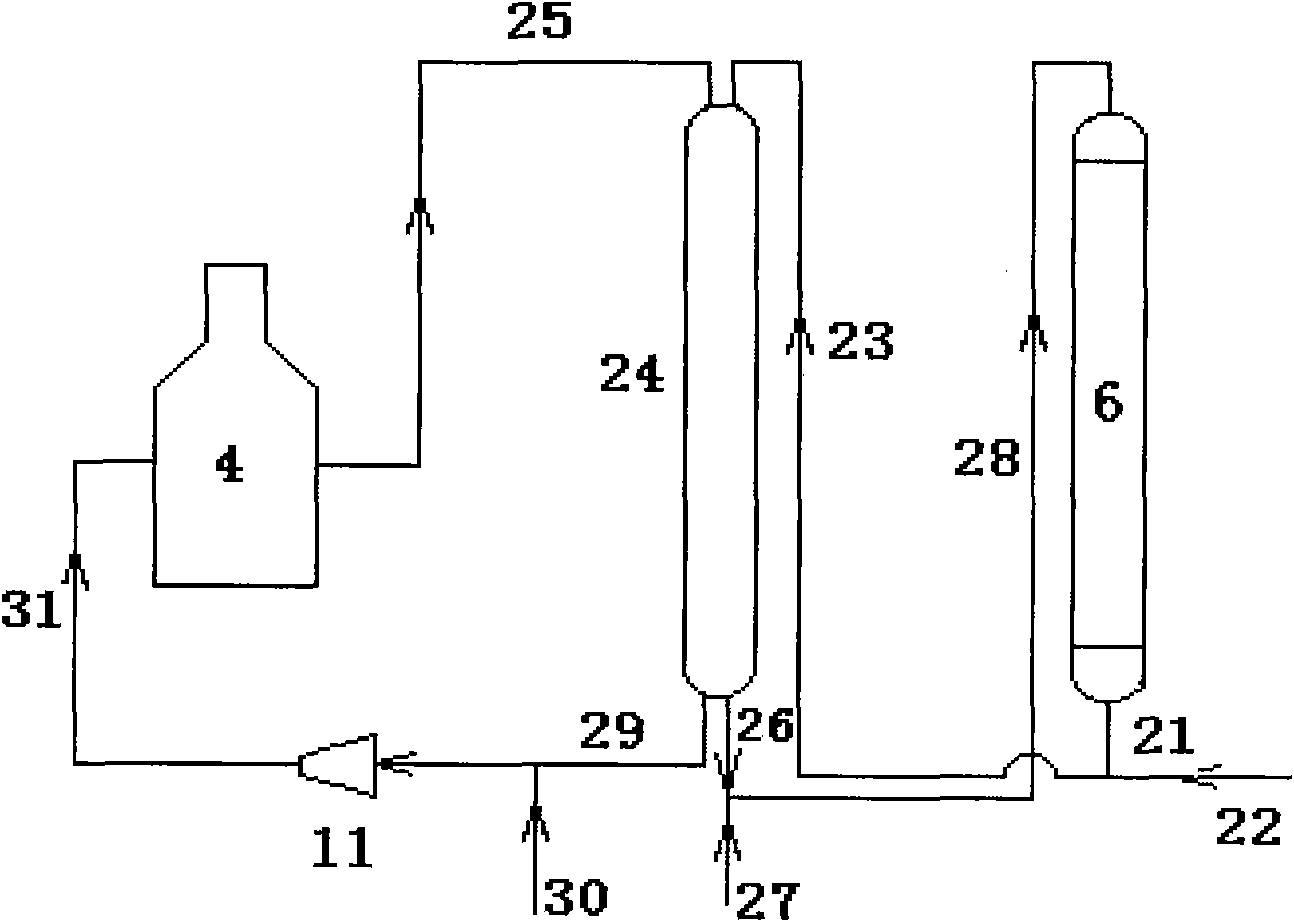

Method used

Image

Examples

example 1

[0032] Catalysts used in the present invention are prepared.

[0033] (1) Preparation of composite carrier

[0034] Get 94.6 grams of pseudo-boehmite (produced by Sasol company, SB powder, alumina content 74% by mass), under stirring, was added into 36 grams of nitric acid aqueous solution with a concentration of 1.1% by mass, stirred for 2 hours to peptize, and added 33.0 grams of HZSM-5 with a silica / alumina molar ratio of 55 Zeolite powder (wherein the zeolite content is 91% by mass), stirred at high speed for 3 hours. Drop the prepared slurry into an oil-ammonia column containing 5.0% by mass ammonia water and drop balls, dry the wet balls at 80°C for 24 hours, and bake them at 550°C for 4 hours to obtain alumina pellets with a HZSM-5 content of 30% by mass .

[0035] (2) Preparation of catalyst

[0036] Get 50 grams of alumina pellets prepared in (1) step, use 50 grams of zinc nitrate 4.7 mass %, mixed rare earth chloride 1.5 mass % (wherein lanthanum oxide accounts ...

example 2

[0039] Prepare alumina pellets containing HZSM-5 zeolite according to the method of Example 1 (1), except that the amount of HZSM-5 zeolite powder is 76.9 grams, and the obtained HZSM-5 content is 50% by mass of alumina pellets .

[0040] Get 50 grams of alumina pellets containing 50 mass % of HZSM-5 zeolite prepared by the above method, prepare catalyst B according to the method of example 1 (2) step, the difference is that the impregnation solution contains 3.0 mass % of chlorinated mixed rare earths, and obtains The specific surface area of Catalyst B is 311 m 2 / g, the bulk density is 0.75 g / ml, the crushing strength is 72 N / cm, the content of zinc oxide in catalyst B is 2.0% by mass, the content of oxidized mixed rare earth is 1.0% by mass, and the content of phosphorus is 2.0% by mass.

example 3

[0044] The following examples carry out the aromatization test.

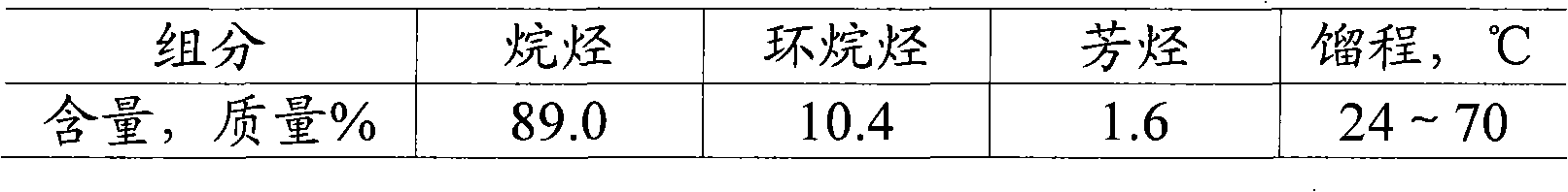

[0045] The aromatization test of Catalyst A was carried out using straight-run light naphtha as raw material. h -1 , The reaction time is 30h, and the results are shown in Table 4.

[0046] Table 1

[0047]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com