Preparation method for sulfoxide and sulphone

A sulfoxide and sulfide technology, which is applied in the field of catalyzing sulfide to produce sulfoxide and sulfone, can solve problems such as poor oxidation effect of macromolecular organic substrates, and achieves short reaction time, simple process flow and simple production process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

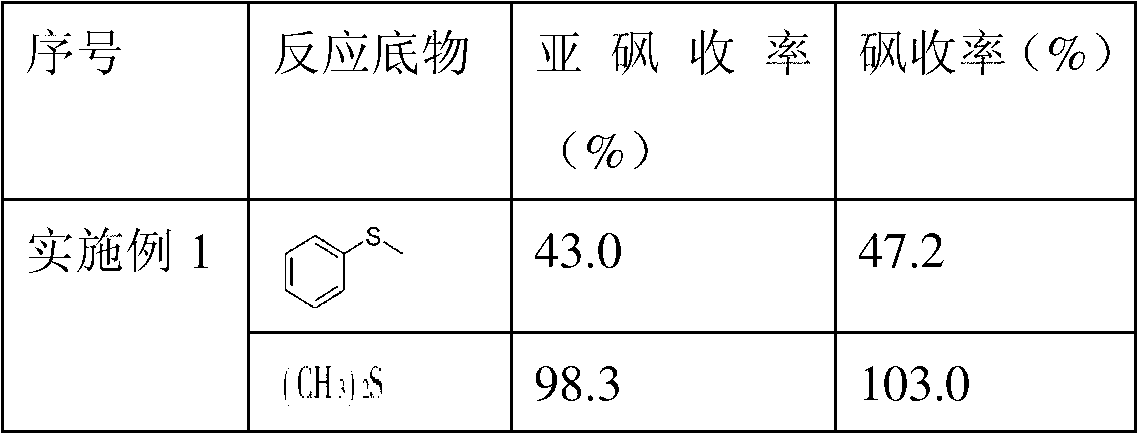

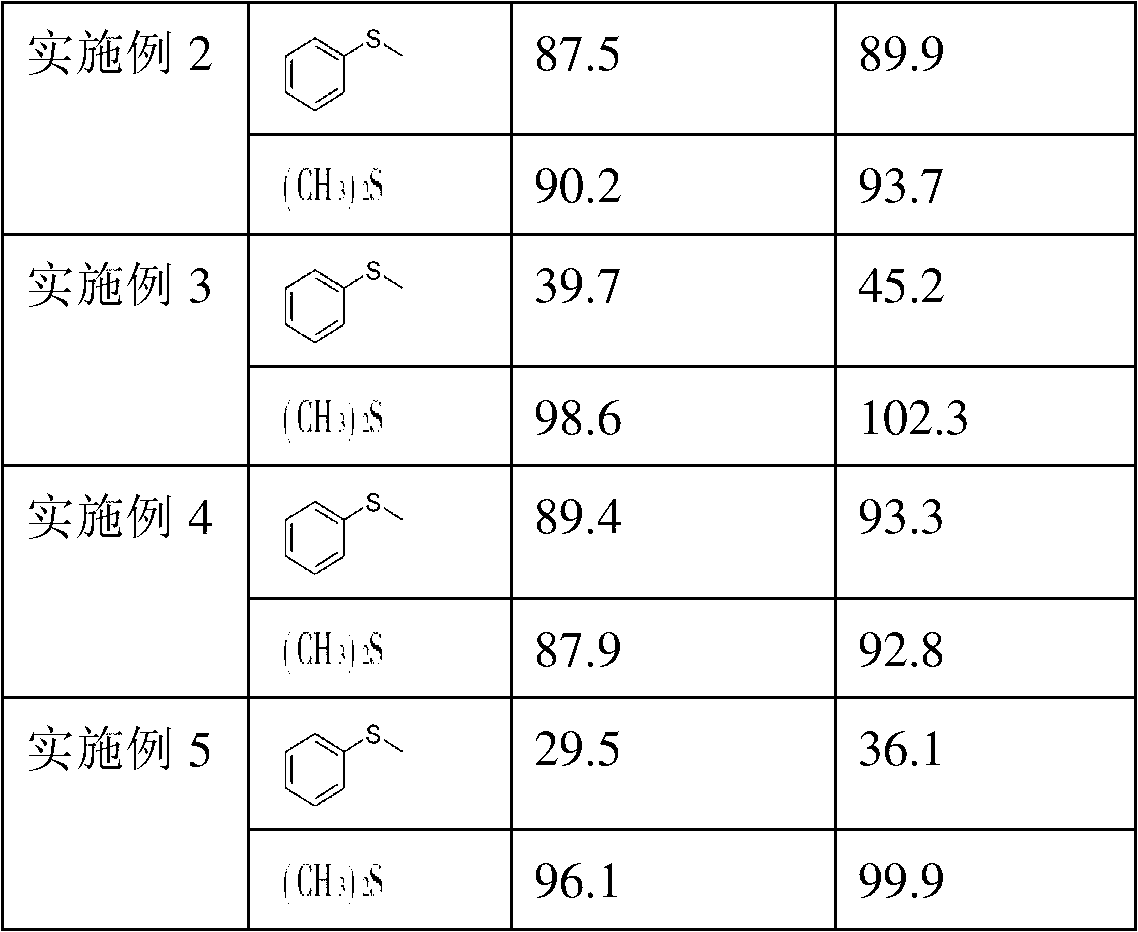

Embodiment 1

[0017] Mix some TS-1 molecular sieve raw powder with silica sol according to the molecular sieve and silica sol weight ratio of 90:10, and turnip powder is 3%, mix molecular sieve, silica sol and turnip powder evenly; extrude the mixture on a twin-screw extruder Slitting; drying at 120°C for 4 hours in a constant temperature blast drying oven; calcining the catalyst in a muffle furnace, raising the temperature to 550°C for 5 hours, and roasting in a muffle furnace for 3 hours at this temperature to obtain the catalyst.

[0018] Using sulfide anisole and dimethyl sulfide as reaction substrates respectively, according to the molar ratio of sulfide: hydrogen peroxide: acetone is 1:1.0:5, and the space velocity is 25, the target product sulfoxide is prepared.

[0019] Using sulfide anisole and dimethyl sulfide as reaction substrates respectively, the target product sulfone was prepared according to the molar ratio of sulfide: hydrogen peroxide: acetone was 1:2.0:5, and the space ve...

Embodiment 2

[0021] Some Ti-MCM-41 molecular sieve raw powder and silica sol according to the molecular sieve and silica sol weight ratio of 90:10, and the turmeric powder is 3%, and the molecular sieve, silica sol and safflower powder are mixed evenly; the mixture is put on a twin-screw extruder Extrude into strips; dry at 120°C for 4 hours in a constant-temperature blast drying oven; use a muffle furnace to calcine the catalyst, and raise the temperature to 550°C for 5 hours; at this temperature, calcine in a muffle furnace for 3 hours to obtain the catalyst.

[0022] Using sulfide anisole and dimethyl sulfide as reaction substrates respectively, according to the molar ratio of sulfide: hydrogen peroxide: acetone is 1:1.0:5, and the space velocity is 25, the target product sulfoxide is prepared.

[0023] Using sulfide anisole and dimethyl sulfide as reaction substrates respectively, the target product sulfone was prepared according to the molar ratio of sulfide: hydrogen peroxide: acetone...

Embodiment 3

[0025] Put some TS-1 molecular sieve raw powder and silica sol according to the molecular sieve and silica sol weight ratio of 30:70, and the turmeric powder is 3%, mix the molecular sieve, silica sol and safflower powder evenly; extrude the mixture on a twin-screw extruder Slitting; drying at 120°C for 4 hours in a constant temperature blast drying oven; calcining the catalyst in a muffle furnace, raising the temperature to 550°C for 5 hours, and roasting in a muffle furnace for 3 hours at this temperature to obtain the catalyst.

[0026] Using sulfide anisole and dimethyl sulfide as reaction substrates respectively, according to the molar ratio of sulfide: hydrogen peroxide: acetone is 1:1.0:5, and the space velocity is 25, the target product sulfoxide is prepared.

[0027] Using sulfide anisole and dimethyl sulfide as reaction substrates respectively, the target product sulfone was prepared according to the molar ratio of sulfide: hydrogen peroxide: acetone was 1:2.0:5, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com