Ti-SBA-15 molecular sieve, modified Ti-SBA-15 molecular sieve, their preparation methods and preparation method of epoxy propane

A technology of ti-sba-15 and molecular sieve, which is applied in the field of preparation of propylene oxide, achieves the effects of increased yield, low preparation cost and improved selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] According to the method for preparing Ti-SBA-15 molecular sieve of the present invention, the method comprises:

[0024] (1) Under the reaction conditions of introducing titanium by liquid phase grafting and in the presence of the first organic solvent, the titanium source and SBA-15 molecular sieve are contacted and reacted in the presence of 100-300W ultrasonic waves, and the product after the contact reaction is solid-liquid separation;

[0025] (2) washing, drying, and roasting the solid product obtained in step (1) from solid-liquid separation,

[0026] Wherein, the titanium source is a general formula of Ti(OR) 4 titanate and / or inorganic titanium source; the first organic solvent is an alcohol compound with the general formula R'OH, where R' is an alkyl group with 1-5 carbon atoms.

[0027] The above-mentioned method for preparing Ti-SBA-15 molecular sieve mainly involves introducing the titanium source into the SBA-15 molecular sieve, selecting common and easy...

Embodiment 1

[0075] (1) Preparation of SBA-15 molecular sieve

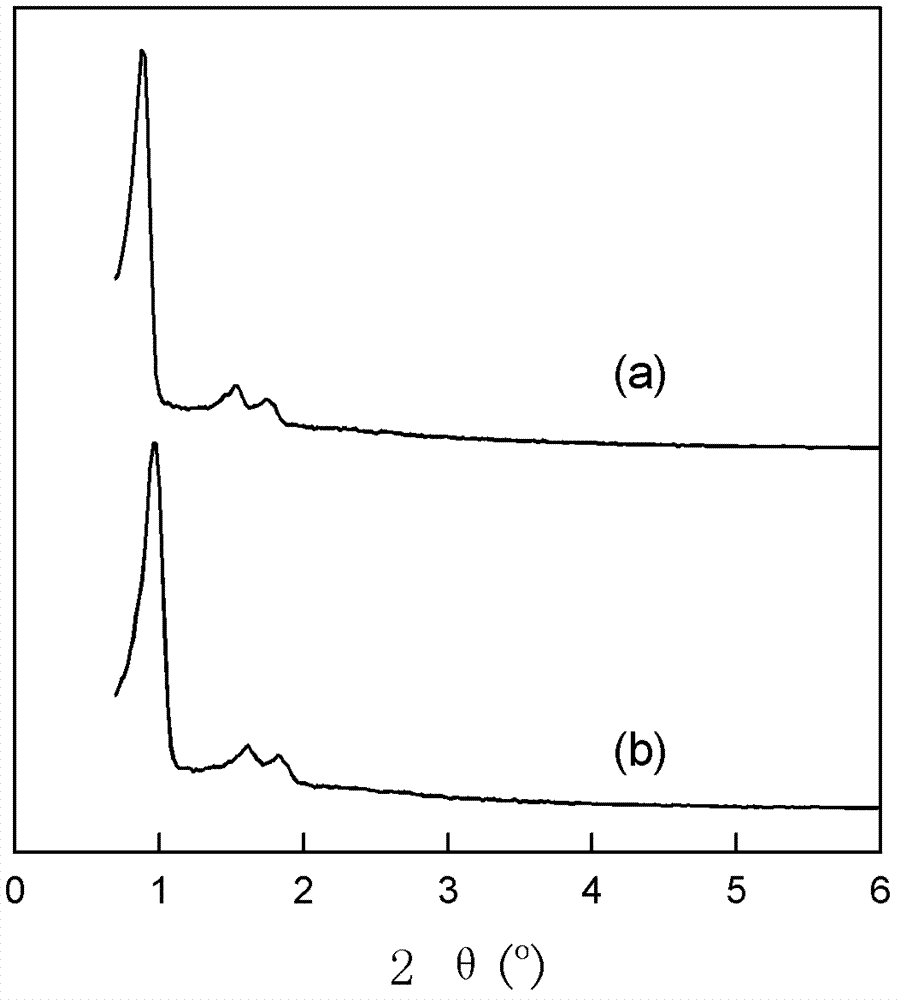

[0076] Add 24.0g of nonionic surfactant P123 to 600g of 2M hydrochloric acid aqueous solution, stir at 35°C for 1 hour; add 51.2g of tetraethyl orthosilicate to the above solution, and stir at 35°C for 24 hours; transfer the above mixture to water Hot pot, hydrothermal crystallization at 100°C for 24 hours. After the hydrothermal reaction, the solid product was separated from the mother liquor, washed with deionized water until neutral, and dried at 110° C. for 3 hours to obtain the original powder of SBA-15. Mix 20.0 g of SBA-15 raw powder with 200 ml of acidified methanol (the volume ratio of methanol to concentrated hydrochloric acid is 20:1), reflux extraction at 80°C for 10 hours, then filter, wash, and vacuum dry at 120°C for 3 hours to obtain SBA -15 molecular sieves. Its X-ray diffraction pattern (XRD) is as figure 1 As shown in (a), it can be seen that the sample has typical SBA-15 molecular sieve mesoporous struct...

Embodiment 2

[0089] (1) Preparation of SBA-15 molecular sieve

[0090] Add 30.6g of nonionic surfactant P123 to 400g of 1M hydrochloric acid aqueous solution, stir at 40°C for 1 hour; add 40.1g of methyl orthosilicate dropwise to the above solution, and stir at 40°C for 24 hours; transfer the above mixture To a hydrothermal kettle, hydrothermal crystallization at 100°C for 24 hours. After the hydrothermal reaction, the solid product was separated from the mother liquor, washed with deionized water until neutral, and dried at 110° C. for 3 hours to obtain the original powder of SBA-15. Mix 20.0 g of SBA-15 raw powder with 200 g of tetrahydrofuran, reflux extraction at 70°C for 6 hours, then filter, wash, and vacuum dry at 120°C for 3 hours to obtain SBA-15 molecular sieve.

[0091] (2) Preparation of Ti-SBA-15 molecular sieve

[0092] Dissolve 6.3g of titanium tetrachloride in 1000g of ethanol, mix with 10.0g of the above-mentioned SBA-15 molecular sieve, and react with stirring for 60 mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com