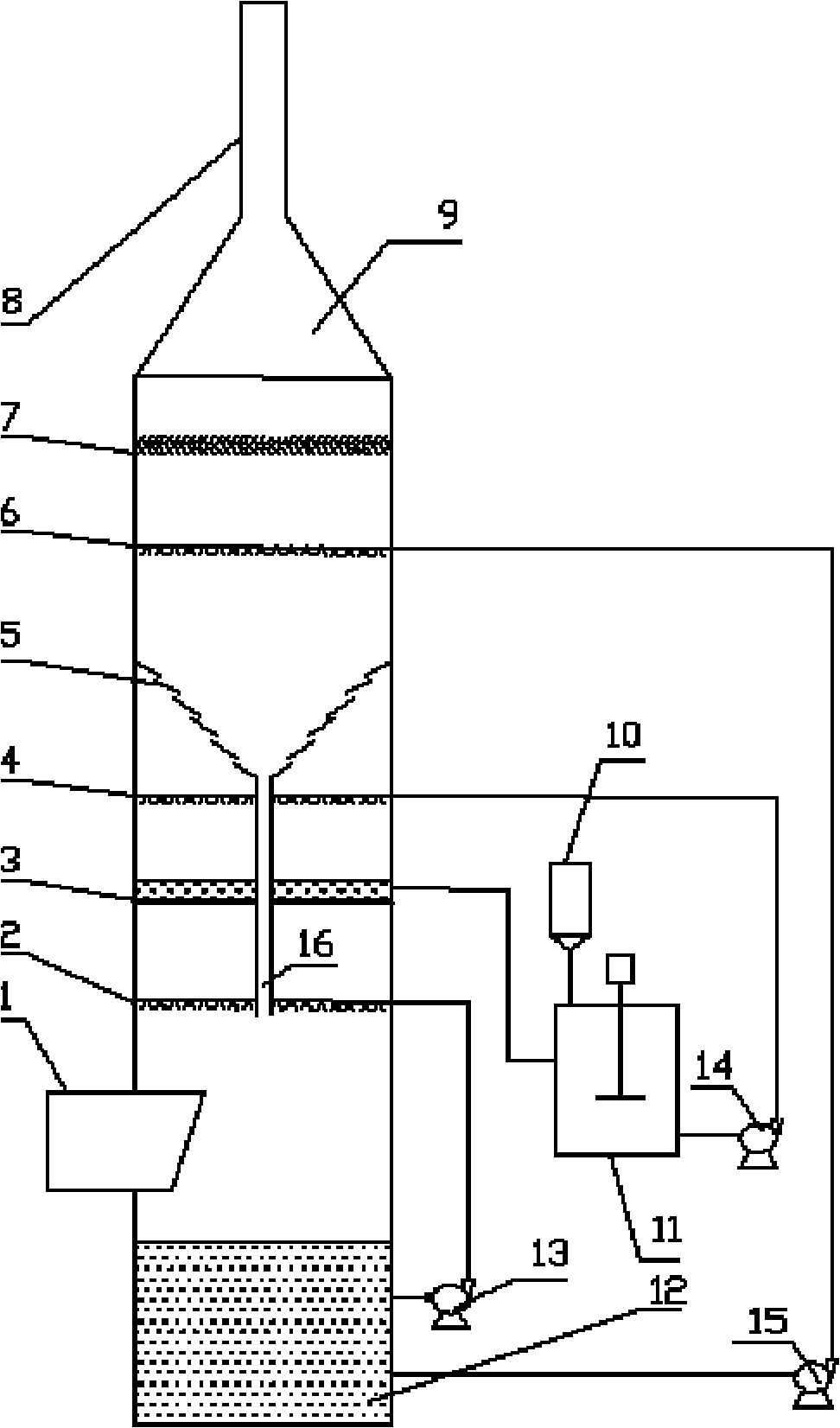

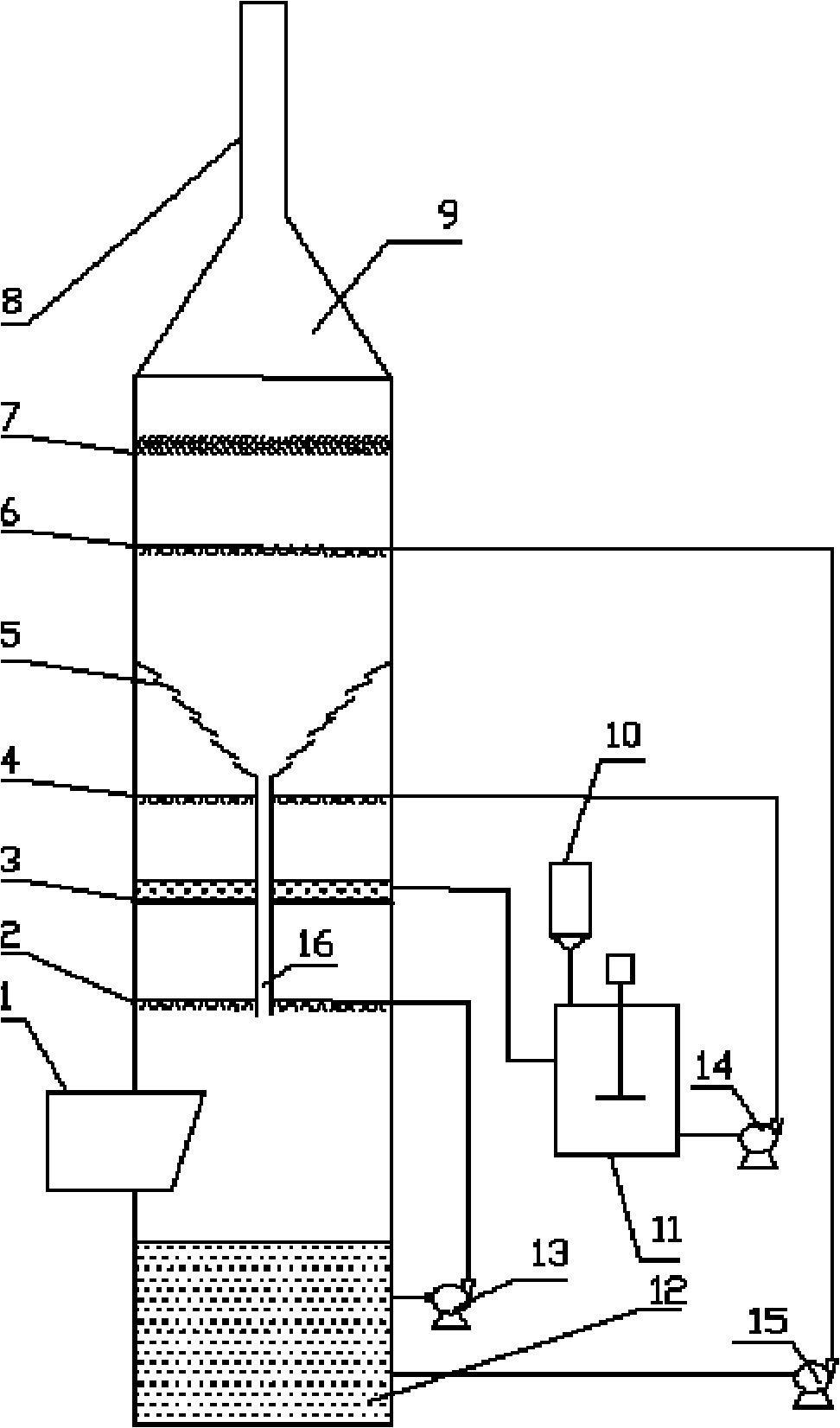

Liquid-phase oxidation multistage absorbed flue gas desulfurization and denitrification technology and device

A technology of desulfurization, denitrification, and liquid-phase oxidation, which is applied in the fields of air quality improvement, chemical instruments and methods, and separation of dispersed particles. The effect of investment cost, reduced floor area, and high denitrification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] at 5m 3 The flue gas desulfurization and denitrification process is simulated on the experimental simulation device at the scale of / h. Flue gas volume 5m 3 / h, the flue gas composition is as follows: O 2 5%, SO 2 is 1000ppm, NO is 400ppm, and the rest is nitrogen, the flue gas temperature is 100°C, and the pressure is 1 atmosphere.

[0059] Hydrogen peroxide and sodium chlorite are configured according to 1: 1 (molar ratio) to be the oxidizing agent that the mass fraction of effective oxidizing component is 10% (except hydrogen peroxide and sodium chlorite in the oxidizing agent, the balance is water), simultaneously Control the pH of the oxidant at 5-6, add ferric chloride with a mass fraction of 0.005% (that is, ferric chloride accounts for 0.005% of the total mass of the oxidant), and the liquid-gas ratio of the liquid phase oxidation is 3-6L / m 3 .

[0060] Calcium hydroxide is used as desulfurizer, and the total liquid-gas ratio of primary desulfurization and ...

Embodiment 2

[0062] at 5m 3 The flue gas desulfurization and denitrification process is simulated on the experimental simulation device at the scale of / h. Flue gas volume 5m 3 / h, the flue gas composition is as follows: O 2 5%, SO 2is 1000ppm, NO is 400ppm, and the rest is nitrogen, the flue gas temperature is 100°C, and the pressure is 1 atmosphere.

[0063] Hydrogen peroxide and sodium chlorite are configured according to 2: 1 (molar ratio) and the mass fraction of effective oxidizing component is the oxidizing agent of 10% (except hydrogen peroxide and sodium chlorite in the oxidizing agent, the balance is water), simultaneously Control the pH of the oxidant at 5-6, add ferric chloride with a mass fraction of 0.005% (that is, ferric chloride accounts for 0.005% of the total mass of the oxidant), and the liquid-gas ratio of the liquid phase oxidation is 3-6L / m 3 .

[0064] Calcium hydroxide is used as desulfurizer, and the total liquid-gas ratio of primary desulfurization and secon...

Embodiment 3

[0066] at 5m 3 The flue gas desulfurization and denitrification process is simulated on the experimental simulation device at the scale of / h. Flue gas volume 5m 3 / h, the flue gas composition is as follows: O 2 5%, SO 2 is 1000ppm, NO is 400ppm, and the rest is nitrogen, the flue gas temperature is 100°C, and the pressure is 1 atmosphere.

[0067] Sodium chlorite solution and sodium hypochlorite solution are configured according to 0.5: 1 (molar ratio) and the mass fraction of effective oxidizing component is 5% oxidizing agent (except hydrogen peroxide and sodium chlorite in the oxidizing agent, the balance is water), add Manganese chloride with a mass fraction of 0.001% (that is, manganese chloride accounts for 0.001% of the total mass of the oxidant), adjusts the pH of the oxidant to 5-6, and the liquid-gas ratio of the liquid-phase oxidation is 3-6L / m 3 .

[0068] Calcium hydroxide is used as desulfurizer, and the total liquid-gas ratio of primary desulfurization and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com