Method for preparing p-xylene and co-producing light olefins by toluene and methylating reagent

A technology for paraxylene and methylation, which is applied in the production of bulk chemicals, condensation between hydrocarbons and non-hydrocarbons to produce hydrocarbons, organic chemistry, etc. It can solve problems such as differences in catalyst characteristics, large catalyst consumption, and catalyst deactivation. , to achieve the effect of improving the conversion rate of raw materials, stable catalyst activity, and small back-mixing of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Embodiment 1: the preparation of catalyst

[0054] The ZSM-5 zeolite molecular sieve raw powder (SiO 2 / Al 2 o 3 =68) Calcinate at 550°C to remove template agent, exchange 4 times with ammonium nitrate solution in 80°C water bath, dry in air at 120°C after exchange, and roast at 550°C for 3 hours to obtain HZSM-5 zeolite molecular sieve.

[0055] HZSM-5 zeolite molecular sieve 20.4kg (dry basis 68.5wt%)+silica sol 23.8kg (SiO 2 25.2wt%)+an appropriate amount of deionized water, mixed and extruded into spherical particles of 2 mm to obtain a shaped HZSM-5 zeolite molecular sieve.

[0056] Use P, La to modify the obtained molding HZSM-5 zeolite molecular sieve, and the steps are respectively:

[0057] (1) molding HZSM-5 zeolite molecular sieve 10kg, 3wt%P(H 3 PO 4 solution) impregnated overnight, after drying, roasting at 550°C for 3 hours to obtain P-HZSM-5 molecular sieve;

[0058] (2) get P-HZSM-5 zeolite molecular sieve 9kg, 3wt% La(La(NO 3 ) 3 solution) impr...

Embodiment 2

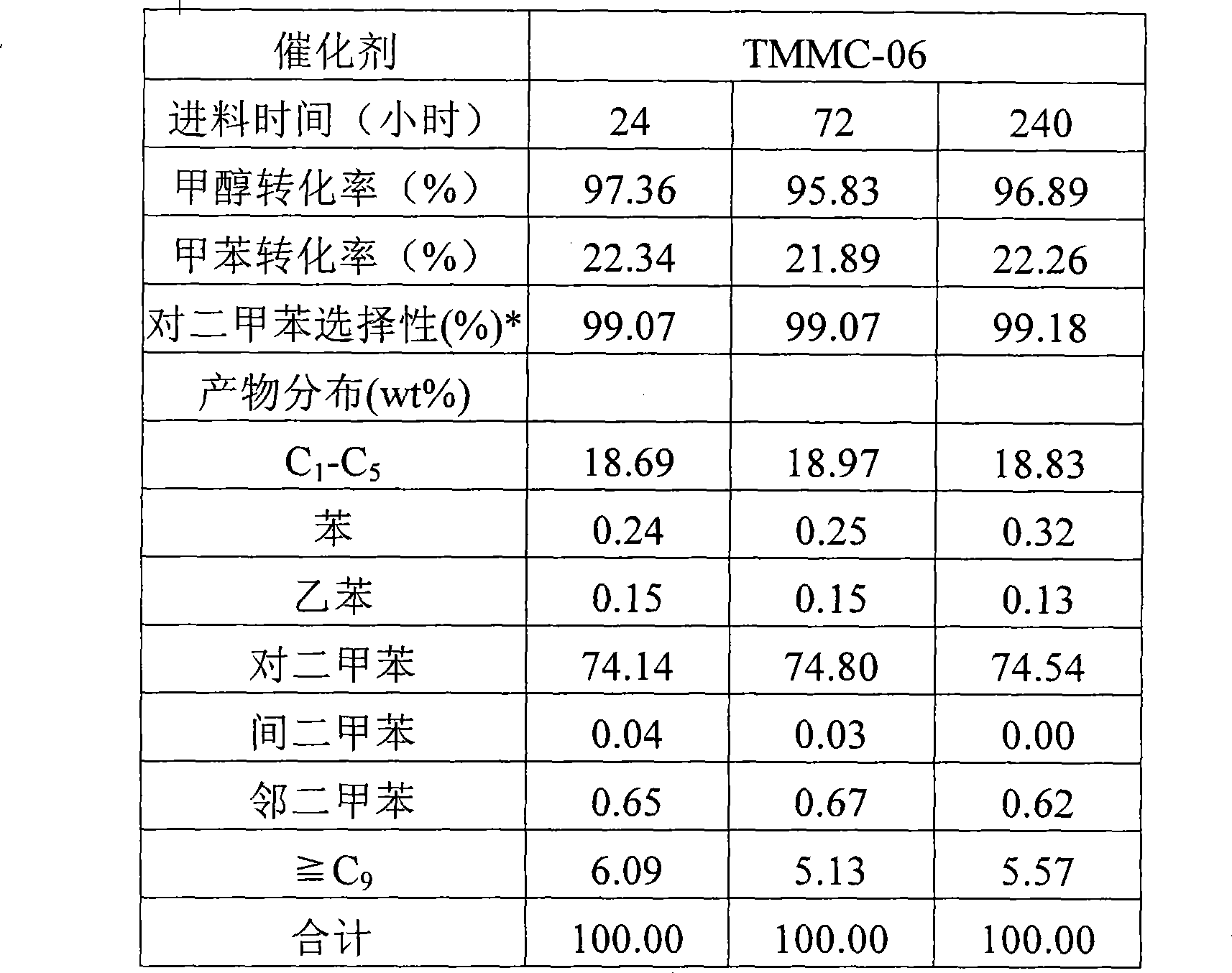

[0060] Example 2: Response Evaluation

[0061] Reaction is carried out on the moving bed reactor, use numbering as TMMC-06 catalyzer in embodiment 1, and reaction conditions are as follows: catalyst load is respectively 3Kg, and reactor inventory is 1.5Kg, fresh catalyzer and regenerated back catalyzer from reactor top Add, slowly move down in the reactor, the coke catalyst flows out from the bottom of the reactor and enters the regenerator for regeneration and activation, and the circulation amount of the catalyst is 0.5Kg / day. The reaction temperature is 450°C, and the raw material toluene / methanol (molar ratio)=2 / 1. Toluene methanol is fed from the top of the reactor after being gasified by the preheater, and the product gas flow flows out from the bottom of the reactor. Using Varian 3800 gas chromatography, CP-WAX 52CB capillary chromatographic column was used for online analysis of product distribution (normalized after removal of toluene), as shown in Table 1. where C ...

Embodiment 3

[0063] Example 3: Response Evaluation

[0064] Reaction is carried out on the moving bed reactor, use numbering as TMMC-06 catalyzer in embodiment 1, and reaction conditions are as follows: catalyst load is respectively 3Kg, and reactor inventory is 1.5Kg, fresh catalyzer and regenerated back catalyzer from reactor top Adding, slowly moving down in the reactor, the carbon-deposited catalyst is released from the bottom of the reactor and enters the regenerator for regeneration, and the circulation amount of the catalyst is 0.5Kg / day. The reaction temperature is 450°C, and the raw material toluene / methanol (molar ratio)=4 / 1. Toluene methanol is fed from the top of the reactor after being gasified by the preheater, and the product gas flow flows out from the bottom of the reactor. Using Varian3800 gas chromatography, CP-WAX52CB capillary chromatographic column online analysis product distribution (normalized after removing toluene), as shown in Table 3. where C 1 -C 5 Varian ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com