Catalytic oxidation method of styrene

A technology for catalytic oxidation and styrene, applied in chemical instruments and methods, molecular sieve catalysts, physical/chemical process catalysts, etc., can solve problems such as harmful emissions and complex production processes, achieve simple production processes, overcome complex production processes, and select sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0013] In the preparation method provided by the present invention, the solvent is selected from alcohols such as water or methanol, ethanol, n-propanol, isopropanol, tert-butanol, isobutanol or ketones such as acetone and methyl ethyl ketone or acetonitrile, Nitriles such as propionitrile and phenylacetonitrile or their mixtures, preferably acetonitrile, acetone, methanol, water or their mixtures, more preferably acetone, methanol and / or acetonitrile.

[0014] In the preparation method provided by the present invention, there is no special requirement on the order of addition. Styrene can be added first, and oxidant or solvent can also be added first.

Embodiment 1

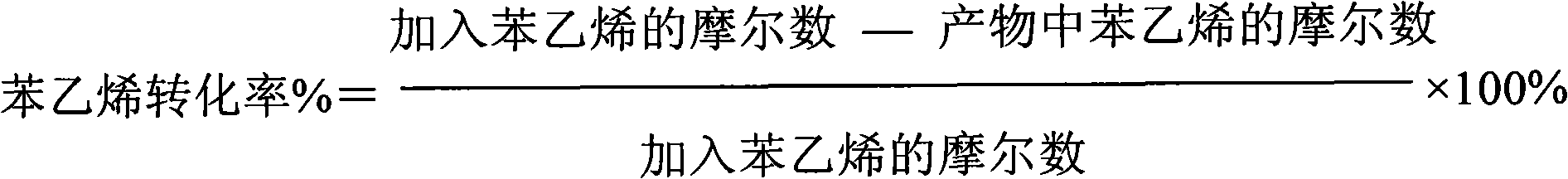

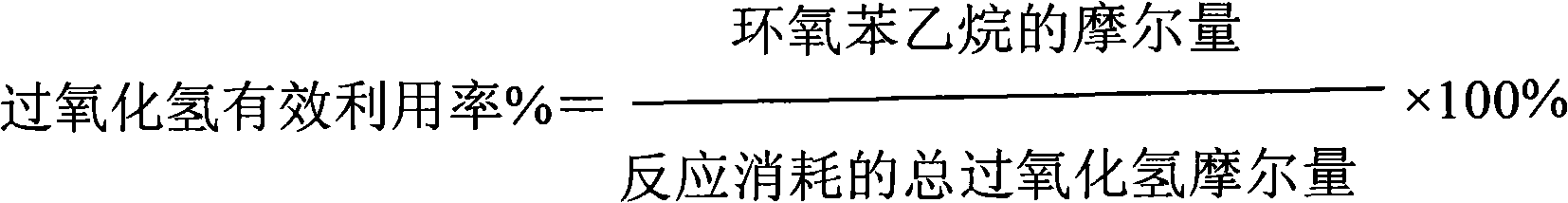

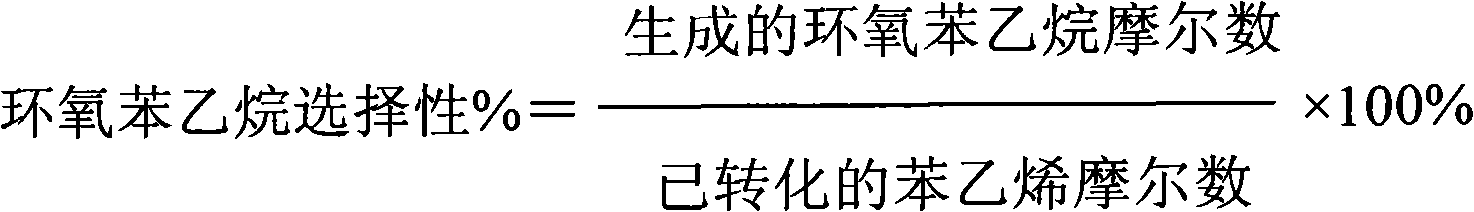

[0032] Styrene, hydrogen peroxide, solvent and catalyst (molar ratio 0.2: 1 of titanium silicon molecular sieve and zinc nitrate) are 1: 2 according to styrene and hydrogen peroxide mol ratio, solvent acetonitrile and catalyst mass ratio are 20: 1, The mass ratio of styrene and catalyst is 10:1, and the reaction is carried out at a temperature of 50° C. and a pressure of 1.5 MPa. After 2 hours of reaction, the conversion rate of styrene was 39%; the effective utilization rate of hydrogen peroxide was 72%; the selectivity of styrene oxide was 61%.

Embodiment 2

[0034] Styrene, hydrogen peroxide, solvent and catalyst (the molar ratio of titanium silicon molecular sieve and zinc phosphate 1: 1) is 1: 2 according to styrene and hydrogen peroxide molar ratio, solvent acetone and catalyst mass ratio are 50: 1, The mass ratio of styrene and catalyst is 20:1, and the reaction is carried out at a temperature of 60° C. and a pressure of 2.5 MPa. After 2 hours of reaction, the conversion rate of styrene was 58%, the effective utilization rate of hydrogen peroxide was 67%, and the selectivity of styrene oxide was 65%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com