Method for simultaneously desulfurizing and denitrating flue gas

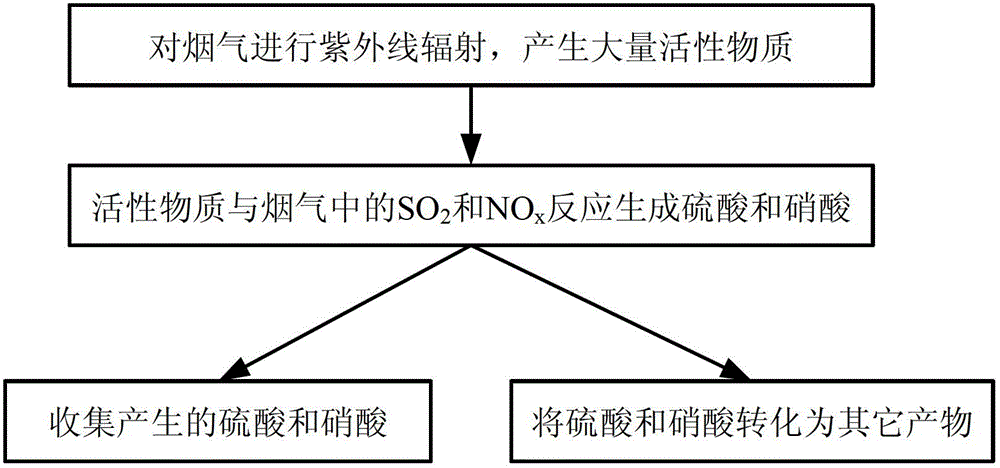

A technology for desulfurization, denitrification, and flue gas, which is applied in the fields of chemical technology and gas pollutant treatment, can solve problems that have not been reported, and achieve the effect of simple operation, high efficiency, and large amount of flue gas treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

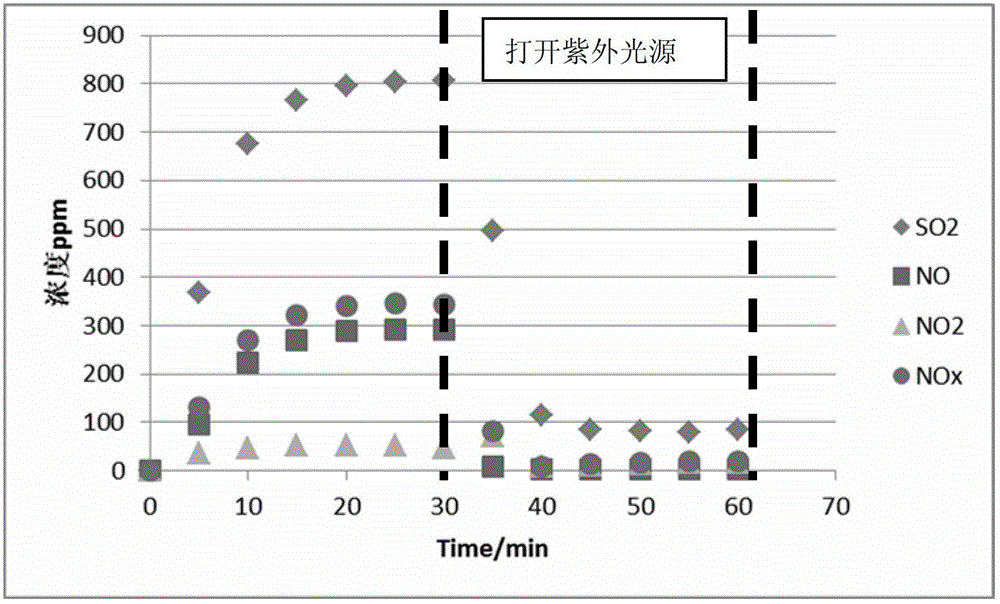

[0030] Example 1: Dynamic SO 2 and NO x (NO+NO 2 ) removal

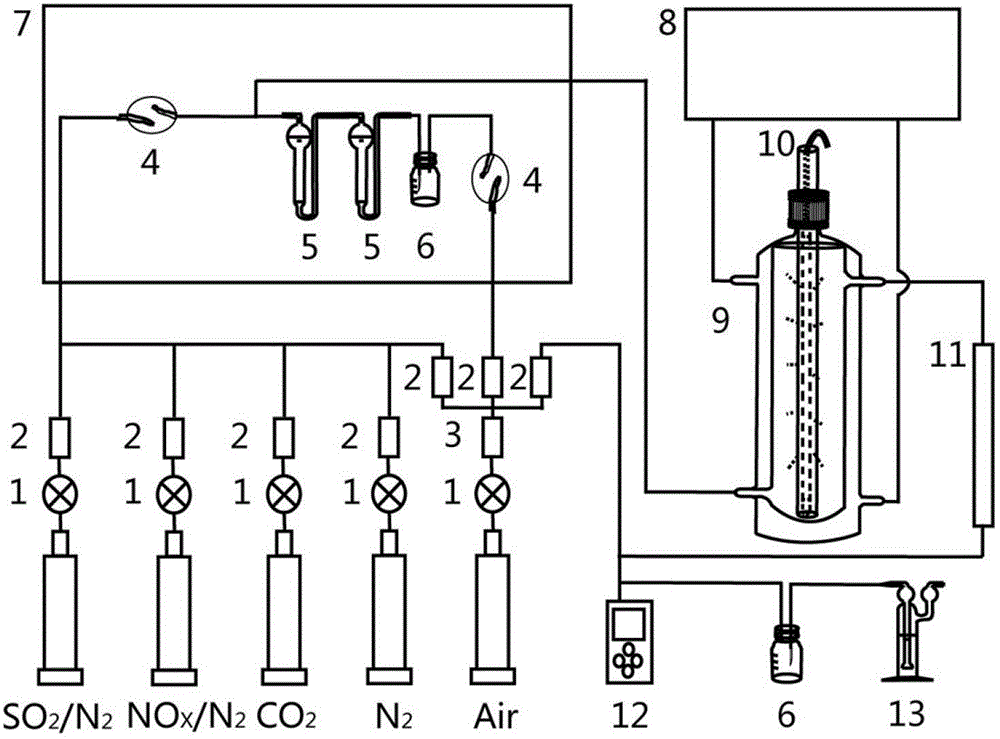

[0031] figure 2 It is a schematic structural diagram of simultaneous desulfurization and denitrification equipment, in which the temperature of the oven 7 and the constant temperature water bath 8 is set at 60-90°C to simulate the temperature range of the actual exhaust gas. As shown in the figure, with N 2 , air, CO 2 , NO x / N 2 , SO 2 / N 2 Gas and H 2 O synthetic simulated flue gas, SO 2 and NO x The concentrations are 800ppm and 350ppm respectively, O 2 Concentration 8%, CO 2 The concentration is 10%, the water vapor content generated by saturated water vapor accounts for 8% of the final simulated flue gas volume, and the rest is N 2 . The mixed simulated flue gas enters the oven 7 at a flow rate of 500 sccm, and the temperature of the simulated flue gas rises to 60°C after passing through the oven 7 and the double-layer water-bath photoreactor 9, and the outlet of the double-layer water-bath phot...

Embodiment 2

[0033] Example 2: Dynamic SO 2 removal of

[0034] Such as figure 2 shown, use N 2 , air, CO 2 , SO 2 / N 2 Gas and H 2 O synthetic simulated flue gas, SO in the synthetic simulated flue gas 2 The content is 800ppm, O 2 Concentration 8%, CO 2 The concentration is 10%, and the water vapor content generated by saturated water vapor accounts for 8% of the final simulated flue gas volume. The simulated flue gas flow rate is 500 sccm, and the temperature is 60°C. Use a flue gas detector analyzer to monitor SO in the outlet flue gas 2 content changes. Such as Figure 4 As shown, in the process of 30min ultraviolet irradiation, SO 2 The removal rate reaches 90%, achieving the purpose of flue gas desulfurization, and the final main product is sulfuric acid.

Embodiment 3

[0035] Embodiment 3: Dynamic NO, NO 2 take off

[0036] Such as figure 2 shown, use N 2 , air, CO 2 , NO x / N 2 Gas and H 2 O synthetic simulated flue gas, NOx (NO+NO 2 ) content is 350ppm, O 2 Concentration 8%, CO 2 The concentration is 10%, the water vapor content generated by saturated water vapor accounts for 8% of the final simulated flue gas volume, the simulated flue gas flow rate is 500 sccm, and the temperature is 60°C. Use a flue gas analyzer to monitor NO and NO in the flue gas at the outlet 2 content changes. Such as Figure 5 As shown, in the process of 30min ultraviolet irradiation, NOx (NO+NO 2 ) The removal rate reaches 95%. To achieve the purpose of flue gas denitrification, the final main product is nitric acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com