Activated carbon treatment system for improving waste heat utilization rate and denitration rate and using method thereof

A treatment system and activated carbon technology, applied in the field of flue gas purification, can solve the problems of poor denitration effect and low heat utilization efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

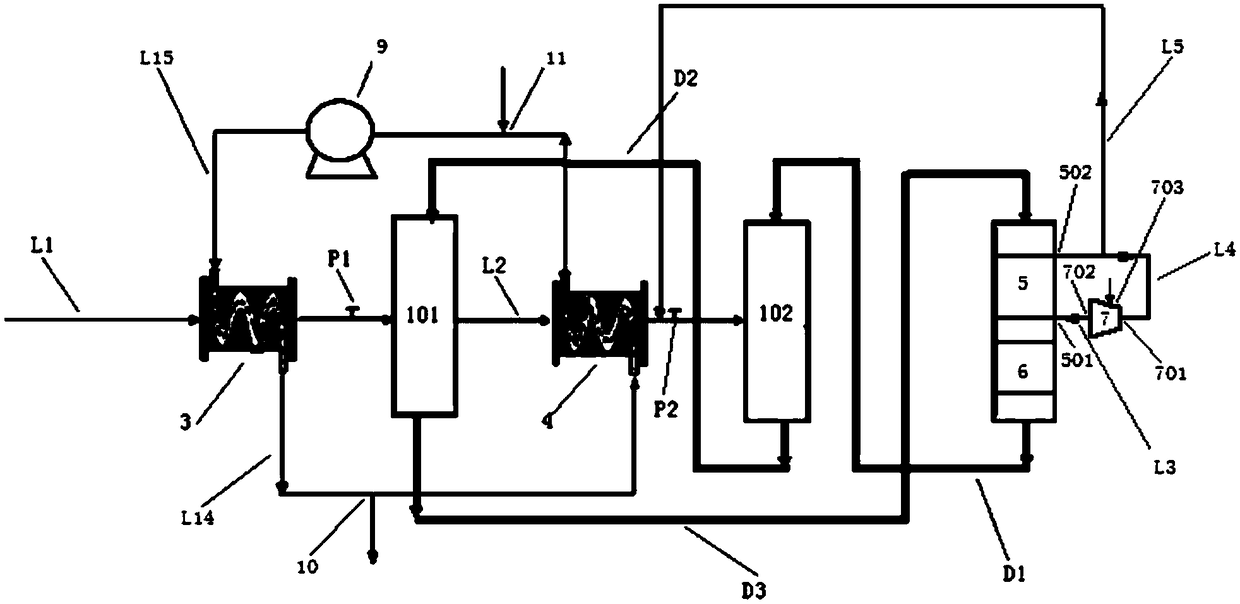

[0142] According to the first embodiment provided by the present invention, an activated carbon treatment system for improving waste heat utilization rate and denitrification rate is provided.

[0143] An activated carbon treatment system for improving waste heat utilization rate and denitrification rate, the activated carbon treatment system includes an activated carbon adsorption tower 1 and an activated carbon desorption tower 2 . The activated carbon adsorption tower 1 is a two-stage adsorption tower, including a first-stage adsorption tower 101 and a second-stage adsorption tower 102 . The activated carbon treatment system also includes raw flue gas delivery pipeline L1, first flue gas heat exchanger 3, second flue gas heat exchanger 4, primary treatment flue gas delivery pipeline L2, first activated carbon delivery device D1, second activated carbon delivery Device D2, the third activated carbon delivery device D3.

[0144] Wherein: the original flue gas delivery pipeli...

Embodiment 1

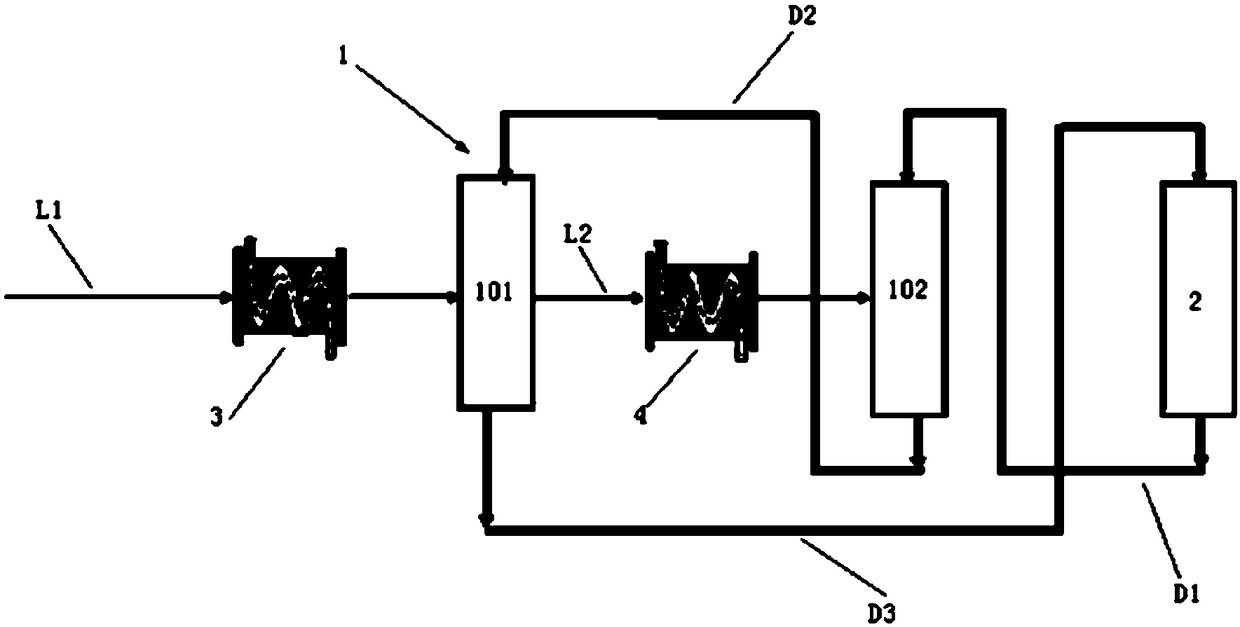

[0167] Such as figure 1 As shown, an activated carbon treatment system that improves waste heat utilization rate and denitrification rate, the activated carbon treatment system includes an activated carbon adsorption tower 1 and an activated carbon desorption tower 2. The activated carbon adsorption tower 1 is a two-stage adsorption tower, including a first-stage adsorption tower 101 and a second-stage adsorption tower 102 . The activated carbon treatment system also includes raw flue gas delivery pipeline L1, first flue gas heat exchanger 3, second flue gas heat exchanger 4, primary treatment flue gas delivery pipeline L2, first activated carbon delivery device D1, second activated carbon delivery Device D2, the third activated carbon delivery device D3.

[0168] Wherein: the original flue gas delivery pipeline L1 is connected to the flue gas inlet of the first-stage adsorption tower 101 . The flue gas outlet of the first-stage adsorption tower 101 is connected to the flue...

Embodiment 2

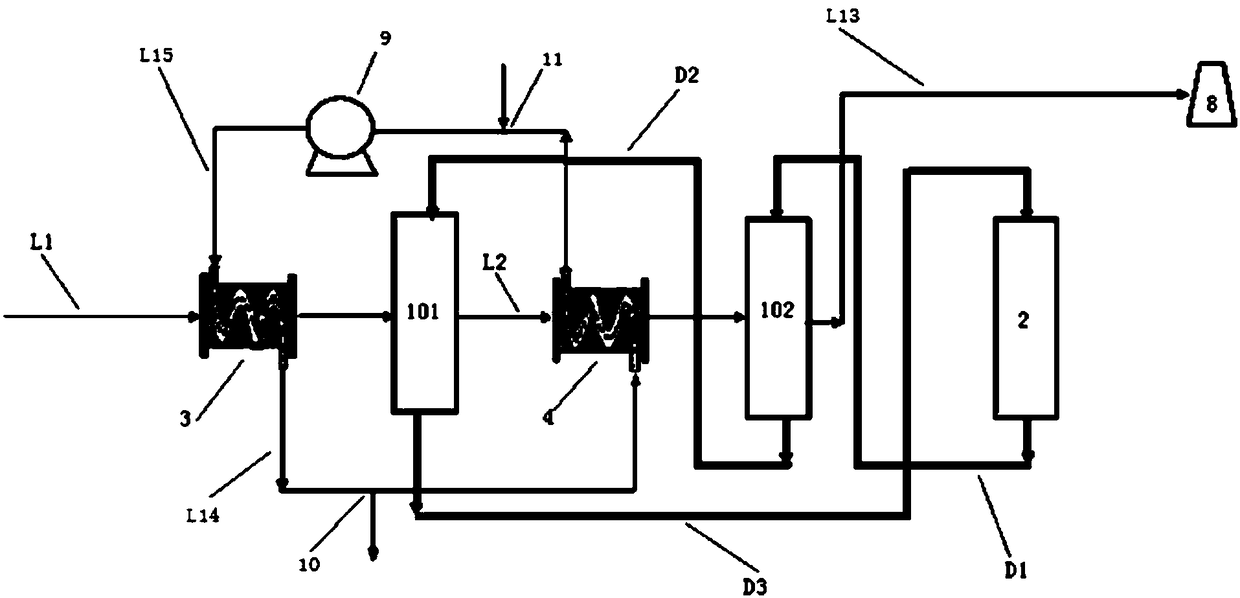

[0170] Such as figure 2As shown, Example 1 is repeated, except that the gas outlet of the first flue gas heat exchanger 3 is connected to the gas inlet of the second flue gas heat exchanger 4 through the first heat exchanger medium delivery pipe L14. The gas outlet of the second flue gas heat exchanger 4 is connected to the gas inlet of the first flue gas heat exchanger 3 through the second heat exchanger medium delivery pipe L15. A fan 5 is provided on the first heat exchanger medium delivery pipeline L3. A fan 9 is provided on the first heat exchanger medium delivery pipeline L3 and / or the second heat exchanger medium delivery pipeline L4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com