Flue gas desulfurization and denitration integrated process

A technology for desulfurization, denitrification, and flue gas, which is applied in the fields of air quality improvement, chemical instruments and methods, and separation of dispersed particles. It can solve the problems of high purchase cost and transportation cost, unfavorable resource recycling, and high waste water treatment costs. Low cost, easy operation and low risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

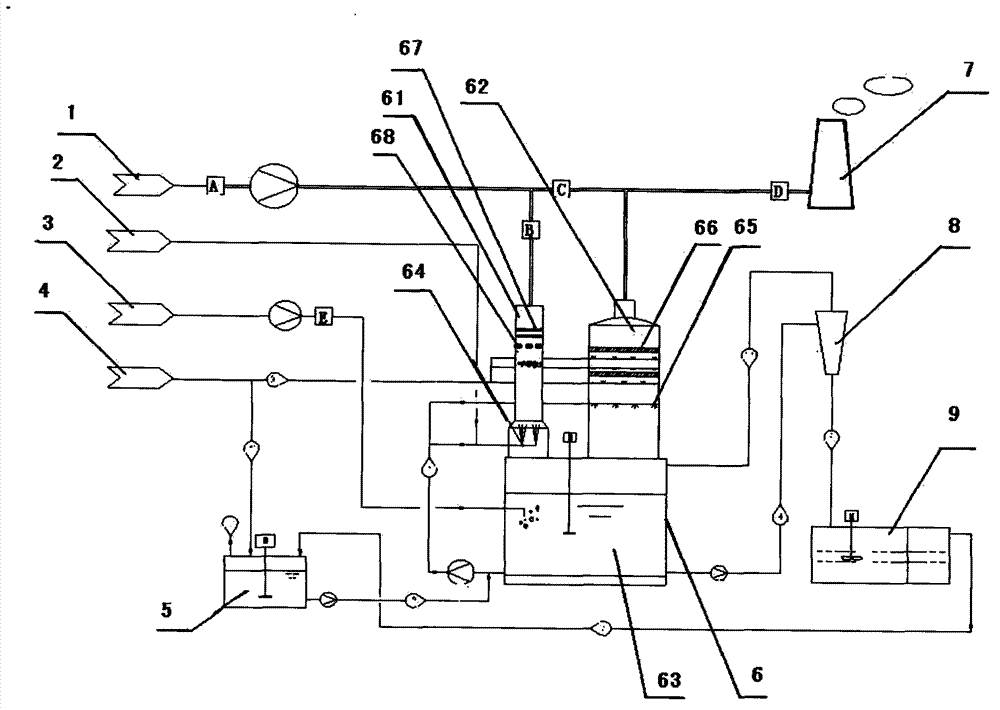

Embodiment 1

[0035] Taking a boiler (10t / h) as an example, the desulfurization and denitrification treatment is carried out according to the integration process of flue gas desulfurization and denitrification described in the present invention. The catalyst layer is composed of 1.2wt% V 2 o 5 , 1.0wt% Fe 2 o 3 It is composed of a sintered body formed by sintering the remaining active coke. The oxidation slurry is composed of 2.0wt% active coke, 0.8wt% ferric oxide, 0.9wt% copper oxide and the rest of water; the number of atomization devices is 6, and along the concentric circle Evenly arranged at intervals of 60 degrees; the absorption slurry is composed of 2.0wt% limestone, 1.0wt% active coke, 0.8wt% ferric oxide, 0.7wt% copper oxide and the rest of water; the oxidation slurry The ratio to flue gas is 3L / m 3 ; The ratio of the absorption slurry to the flue gas is 15L / m 3 ; In the high-speed absorption stage, the flue gas velocity is 10-25m / s; in the low-speed absorption stage, the f...

Embodiment 2

[0039] Taking a boiler (10t / h) as an example, the desulfurization and denitrification treatment is carried out according to the integration process of flue gas desulfurization and denitrification described in the present invention. The catalyst layer is composed of 1.8wt% V 2 o 5 , 1.2wt% Fe 2 o 3 It is composed of a sintered body formed by sintering the remaining active coke. The oxidation slurry is composed of 1.2wt% active coke, 1.2wt% ferric oxide, 1.2wt% copper oxide and the rest of water; the number of atomization devices is 6, and along the concentric circle Evenly arranged at intervals of 60 degrees; the absorption slurry is composed of 2.5wt% limestone, 1.5wt% active coke, 1.5wt% ferric oxide, 1.0wt% copper oxide and the rest of water; the oxidation slurry The ratio to flue gas is 3L / m 3 ; The ratio of the absorption slurry to the flue gas is 15L / m 3 ; In the high-speed absorption stage, the flue gas velocity is 10-25m / s; in the low-speed absorption stage, the f...

Embodiment 3

[0043] Taking a boiler (10t / h) as an example, the desulfurization and denitrification treatment is carried out according to the integration process of flue gas desulfurization and denitrification described in the present invention. The catalyst layer is composed of 0.8wt% V 2 o 5 , 0.7wt% Fe 2 o 3 It is composed of a sintered body formed by sintering the remaining active coke. The oxidation slurry is composed of 1.2wt% active coke, 0.5wt% ferric oxide, 0.8wt% copper oxide and the rest of water; the number of atomization devices is 6, and along the concentric circle Evenly arranged at intervals of 60 degrees; the absorption slurry is composed of 1.5wt% limestone, 1.5wt% active coke, 1.0wt% ferric oxide, 0.5wt% copper oxide and the rest of water; the oxidation slurry The ratio to flue gas is 5L / m 3 ; The ratio of the absorption slurry to the flue gas is 20L / m 3 ; In the high-speed absorption stage, the flue gas velocity is 10-25m / s; in the low-speed absorption stage, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com