System and method for desulphurization and denitration

A technology of desulfurization and denitrification and ammonium sulfate solution, which is applied in the desulfurization and denitrification system and its desulfurization and denitrification field, can solve the problems of ammonia escape, achieve the effects of solving ammonia escape, process stability, ammonia escape and aerosol problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

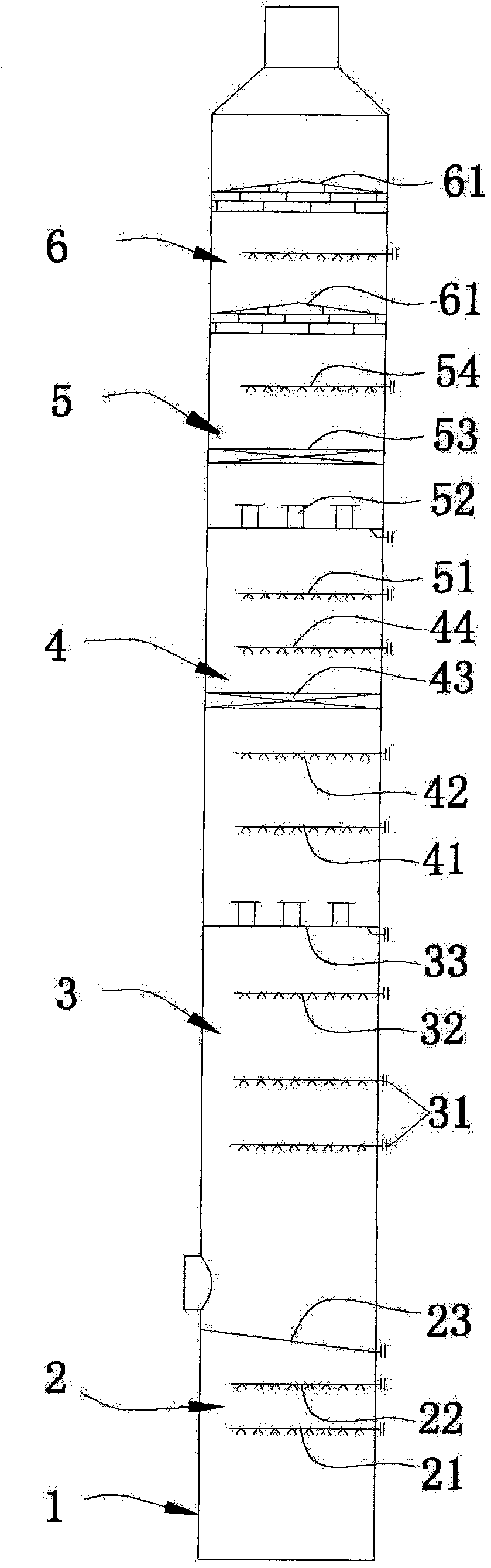

[0024] Examples, see figure 1 , a desulfurization and denitrification system provided in this embodiment, which includes a tower body 1, the lower part of the tower body 1 is provided with a flue gas inlet 11, and the lower part of the flue gas inlet 11 is provided in the tower body 1 Oxidation section 2, corresponding to the position above the flue gas inlet 11, is located in the tower body 1 and is provided with a concentration section 3, an absorption section 4, a purification washing section 5 and a demister section 6 in sequence from bottom to top.

[0025] The oxidation section 2 includes an oxidation air distributor 21 , a gas-liquid distributor 22 and a separator 23 arranged in sequence from bottom to top.

[0026] The concentration section 3 includes an emergency cooling spray layer 31, a secondary circulating fluid spray layer 32, and a primary circulating fluid accumulation tank 33 arranged in sequence from bottom to top, and the primary circulating fluid accumulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com