Simultaneous desulfuration and denitration technique by wet flue gas method

A technology for desulfurization and denitrification and flue gas, which is applied in the direction of separation methods, air quality improvement, chemical instruments and methods, etc., can solve the problems of high operating costs, failure to consider the connection of absorbents, and the consumption of expensive urea, etc., to reduce overall costs and desulfurization The effect of high denitrification efficiency and less investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

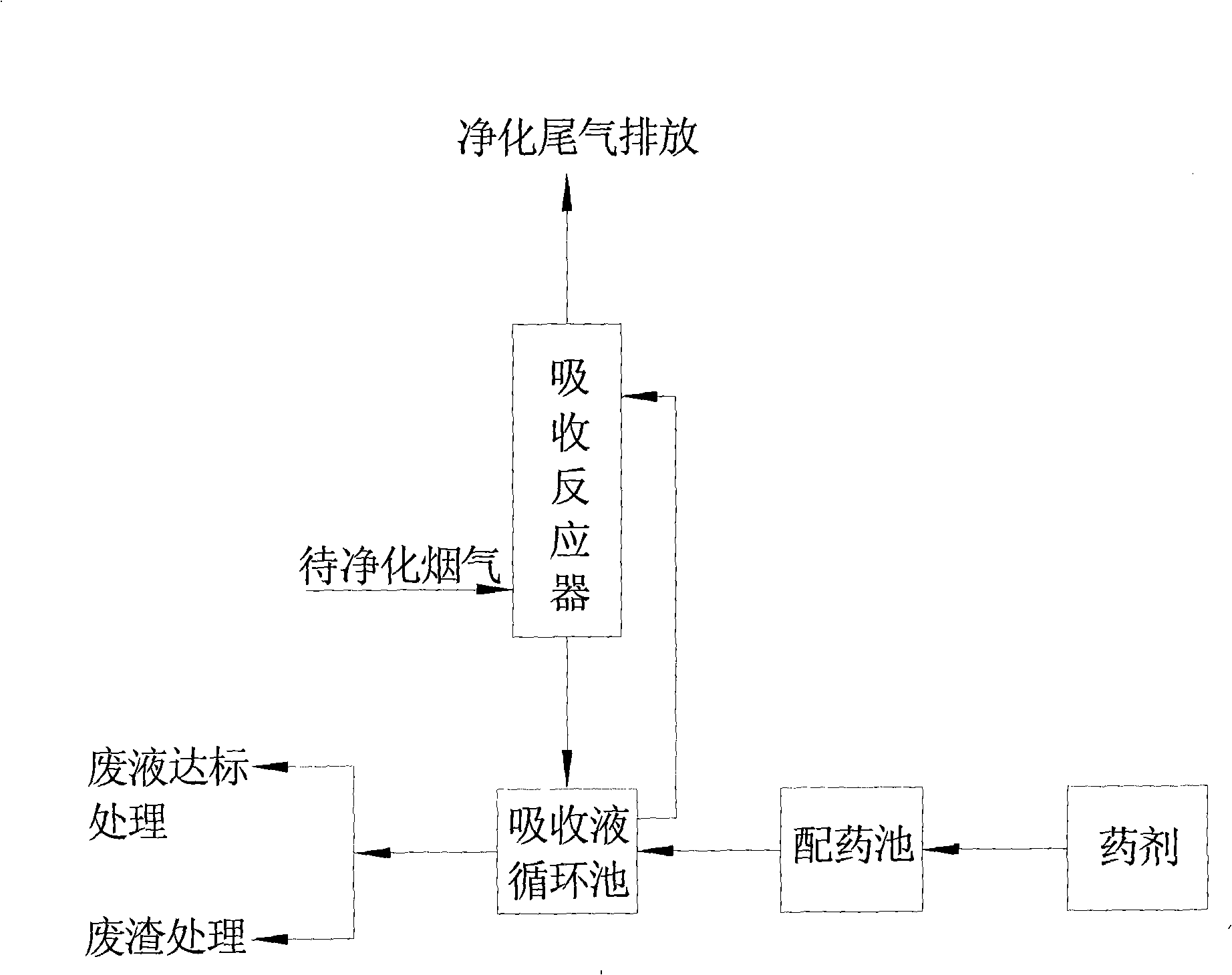

Method used

Image

Examples

Embodiment 1

[0017] Configure a slurry containing 5% lime, add 5% urea, 0.04% potassium permanganate and mix evenly to form a suspension, which is used as an absorbent for simultaneous desulfurization and denitrification of flue gas, and fully reverses with the flue gas in the swirl plate tower contacts, complete SO in the tower 2 , NO x removal. The test results of the purified flue gas show that the denitrification efficiency of 75% to 95% and the desulfurization efficiency of more than 90% can be achieved.

Embodiment 2

[0019] Configure a slurry containing 5% limestone, add 10% urea, 0.02% potassium permanganate and mix evenly to form a suspension, which is used as an absorbent for simultaneous desulfurization and denitrification of flue gas, and fully contacts with the flue gas in the spray tower , complete SO in the tower 2 , NO x removal. The test results of the purified flue gas show that the denitrification efficiency of 65% to 85% and the desulfurization efficiency of more than 90% can be achieved.

Embodiment 3

[0021] Configure a slurry containing 15% limestone, add 8% urea, 0.04% H 2 o 2 Mix evenly to form a suspension, which is used as an absorbent for simultaneous wet desulfurization and denitrification of flue gas. In the packed tower, it is fully contacted with the flue gas in reverse, and the SO2 is completed in the tower. 2 , NOx removal. The test results of the purified flue gas show that the denitrification efficiency of 75% to 90% and the desulfurization efficiency of more than 90% can be achieved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com