Multi-layer fluidized bed two-stage activated carbon/coke flue gas simultaneous-desulfurization and denitrification system and method

A multi-layer fluidized bed, desulfurization and denitrification technology, applied in the field of multi-layer fluidized bed two-stage activated carbon/coke flue gas simultaneous desulfurization and denitrification system, can solve the problems that hinder the popularization and application of activated carbon/coke desulfurization and denitrification process, discontinuous operation, Problems such as high pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

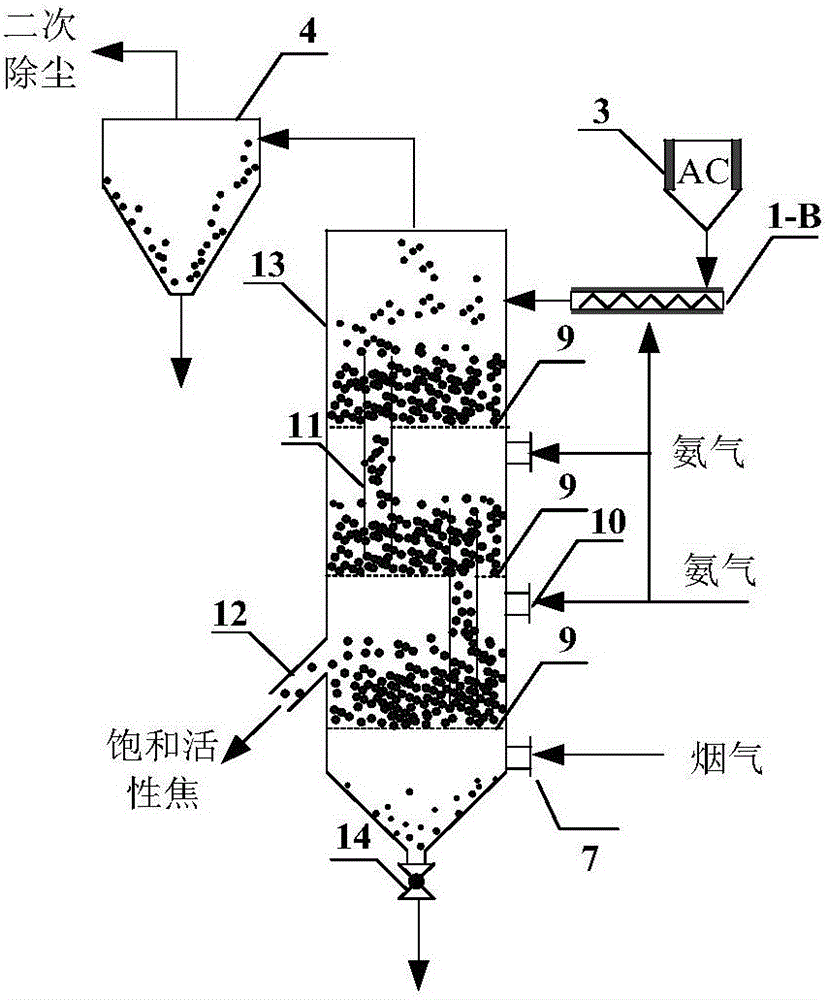

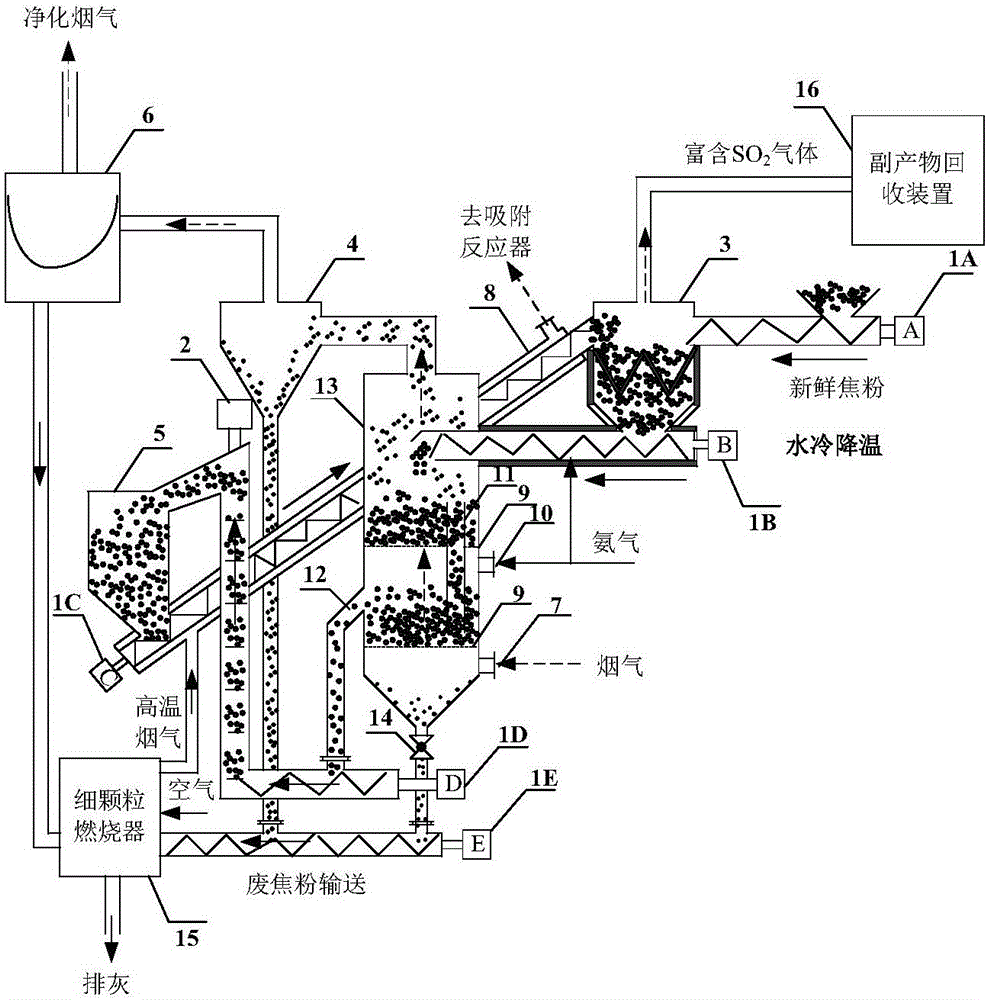

[0085] Such as figure 1 As shown, the desulfurization and denitrification multilayer fluidized bed reactor 13 is a three-layer overflow tube multilayer fluidized bed, the uppermost two layers (ie, the first and second layers) of the fluidized bed are used for denitrification, and the third layer is fluidized The bed is used for desulfurization, and two adjacent fluidized beds are separated by a distribution plate 9. After regeneration, activated carbon / coke and fresh activated carbon / coke are fed into the first layer of fluidized bed through activated carbon / coke conveyor 1B, and the activated carbon / coke is transported In device 1B, activated carbon / coke pre-adsorbs part of the ammonia gas, and at the same time, ammonia gas is injected under the distribution plate of the first fluidized bed. Contact to further remove NO from the flue gas x , the activated carbon / coke particles that have initially participated in the denitrification enter into the second fluidized bed through...

Embodiment 2

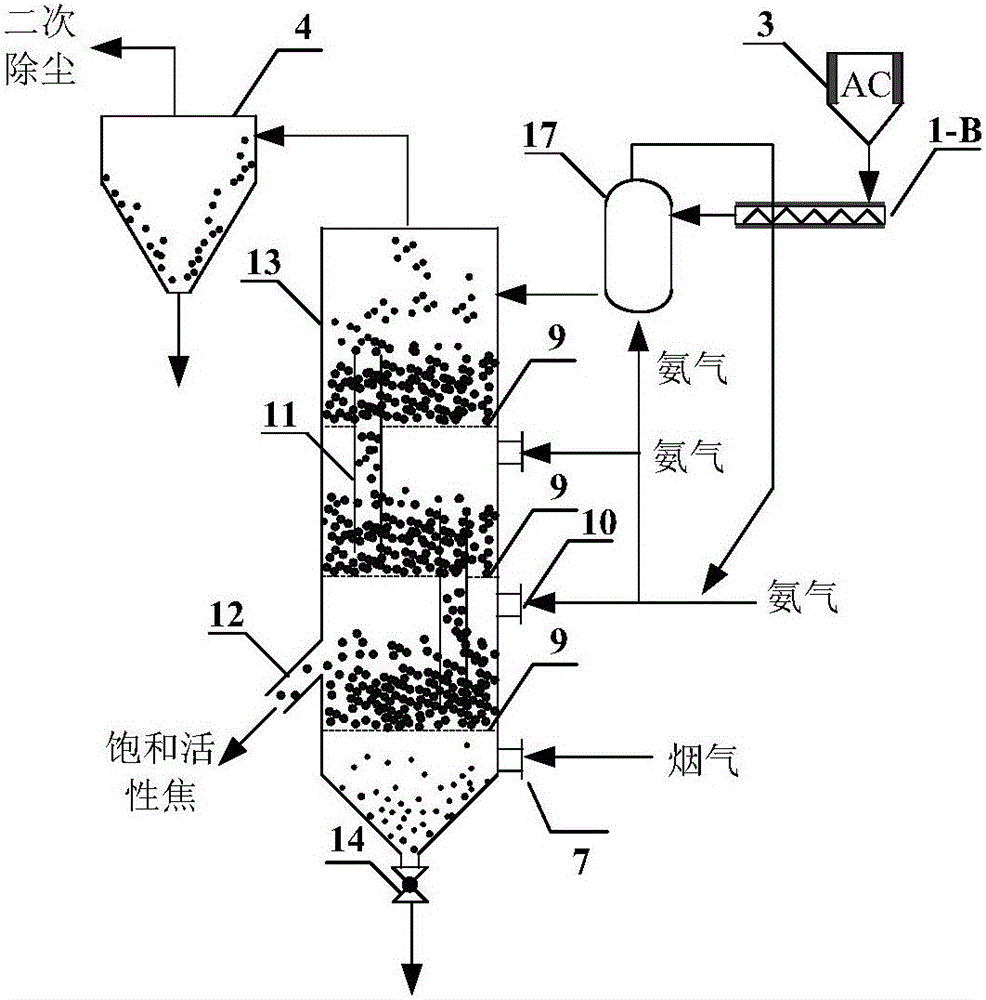

[0087] Such as image 3 shown, with figure 1 the difference is image 3 A ammonia pre-adsorption reactor 17 is added in the reactor, and the pre-adsorption of ammonia is completed in the reactor 17. The activated carbon / coke conveyor 1B firstly feeds the regenerated activated carbon / coke and fresh activated carbon / coke continuously into the ammonia pre-adsorption reactor 17, introduces a part of the ammonia gas into the ammonia pre-adsorption reactor, and sends the activated carbon / coke after adsorbing ammonia to the ammonia pre-adsorption reactor 17. into the desulfurization and denitrification multilayer fluidized bed reactor 13. Adding an ammonia pre-adsorption reactor can make the activated carbon / coke surface adsorb ammonia in advance and improve the denitrification efficiency. Preferably, the ammonia pre-adsorption reactor is a moving bed reactor.

Embodiment 3

[0089] Such as Figure 4 shown, with figure 1 The difference is that the desulfurization and denitrification multilayer fluidized bed reactor 13 does not have an overflow pipe inside, and directly adopts the form of a porous plate, and the activated carbon / coke particles flow down to the next fluidized bed through the holes on the distribution plate 9, and the distribution plate The porosity is 20% to 50%, depending on the residence time of activated carbon / coke.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com