Method for automatically controlling desulphurization and denitration by flue gas based on pH value and ORP value and apparatus thereof

A desulfurization, denitrification and flue gas technology, applied in chemical instruments and methods, separation methods, air quality improvement and other directions, can solve the problems of unsatisfactory denitrification efficiency and low efficiency, and achieve resource utilization of by-products, simple process flow, The effect of low investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

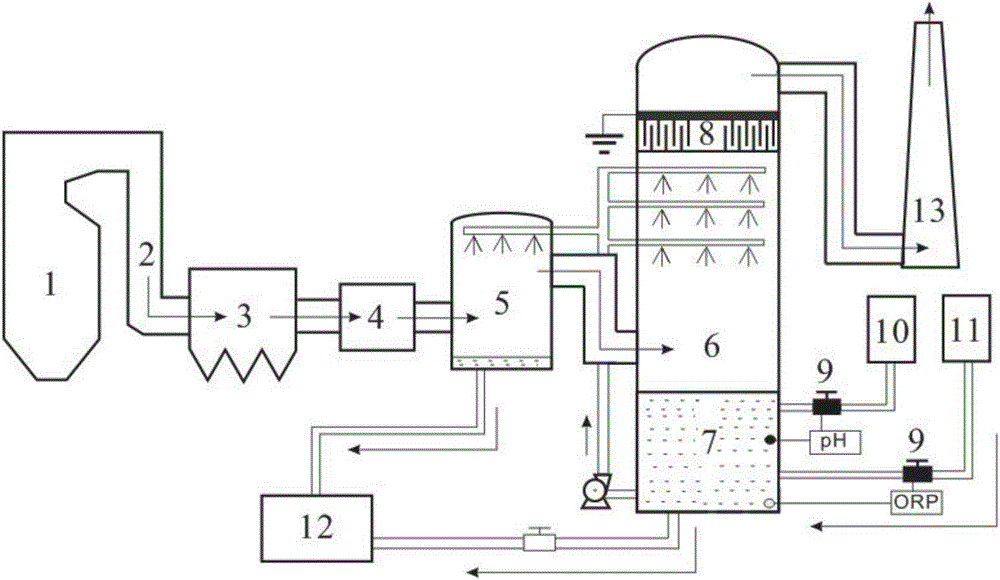

[0049] The layout of the flue gas purification device is as follows: figure 1 As shown, the treated flue gas is coal-fired boiler flue gas, and the flue gas, soot, SO 2 and NO x (x=1 or 2) concentration is 5000mg / m 3 , 2000mg / m 3 and 450mg / m 3 , the flue gas temperature at the boiler outlet is 120°C, and the gas volume is 10,000m 3 / h. After Venturi dust removal, the smoke concentration is reduced to 50mg / m 3 . O 3 Oxidize NO, the oxidation rate is about 78%~86%, and the residual ozone concentration at the outlet is 75~90mg / m 3 . Use the ammonium sulfite absorption solution with tetravalent sulfur concentration of 0.8mol / L, control pH value of 6.0~6.5, ORP value of -150mV~-75mV to wash the above pre-oxidized flue gas, the average desulfurization efficiency is about 98%, and the denitrification efficiency is about 98%. The efficiency is about 85%, and the ammonia escape concentration is lower than 4.1mg / m 3 .

Embodiment 2

[0051] The layout of the flue gas purification device is as follows: figure 1 shown. The flue gas is treated the same as the flue gas in Example 1, and the gas volume is 10000m 3 / h. After electrostatic precipitator, the dust concentration is reduced to 80mg / m 3 . The flue gas oxidation process uses O 3 Injection mode occurs, injecting O 3 Concentration 600mg / m 3 , the flue gas NO oxidation rate is 72%~76.5%, and the residual ozone concentration at the outlet is 35~45mg / m 3, using the ammonium sulfite absorption liquid with tetravalent sulfur concentration of 0.8mol / L, pH value of 6.0~6.5, and ORP value of -75mV~-0mV to wash the flue gas. The average flue gas absorption and desulfurization efficiency is about 95%, and the denitrification The efficiency is about 72%, and the ammonia escape concentration is lower than 3.5mg / m 3 .

Embodiment 3

[0053] The layout of the flue gas purification device is as follows: figure 1 As shown, the flue gas treatment situation is the same as in Example 1, and the treatment gas volume is 100m 3 / h. After Venturi dust removal, the smoke concentration is reduced to 50mg / m 3 . The oxidation process uses O 3 Injection method, inject O 3 Concentration 1000mg / m 3 , the flue gas NO oxidation rate is between 85% and 89%, and the residual ozone concentration at the outlet is 100 to 150mg / m 3 . The circulating absorption liquid adopts tetravalent sulfur concentration of 0.8mol / L, the pH is controlled within the range of 5.5~6.0, the ORP value is -150mV~-75mV, NO x (x=1 or 2) The average removal efficiency of absorption is 83%, SO 2 The absorption and removal efficiency is always maintained in the range of 93%~95%, and the ammonia escape concentration is lower than 2.5mg / m 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com