Exbaust gas purification method and device by pulse corona dicharging method

A pulsed corona and flue gas purification technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of low droplet collection efficiency, difficulty in adjusting and maintaining system water and ammonium salt balance, etc. The effect of high collection efficiency of by-products, improving quality and high desulfurization and denitrification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

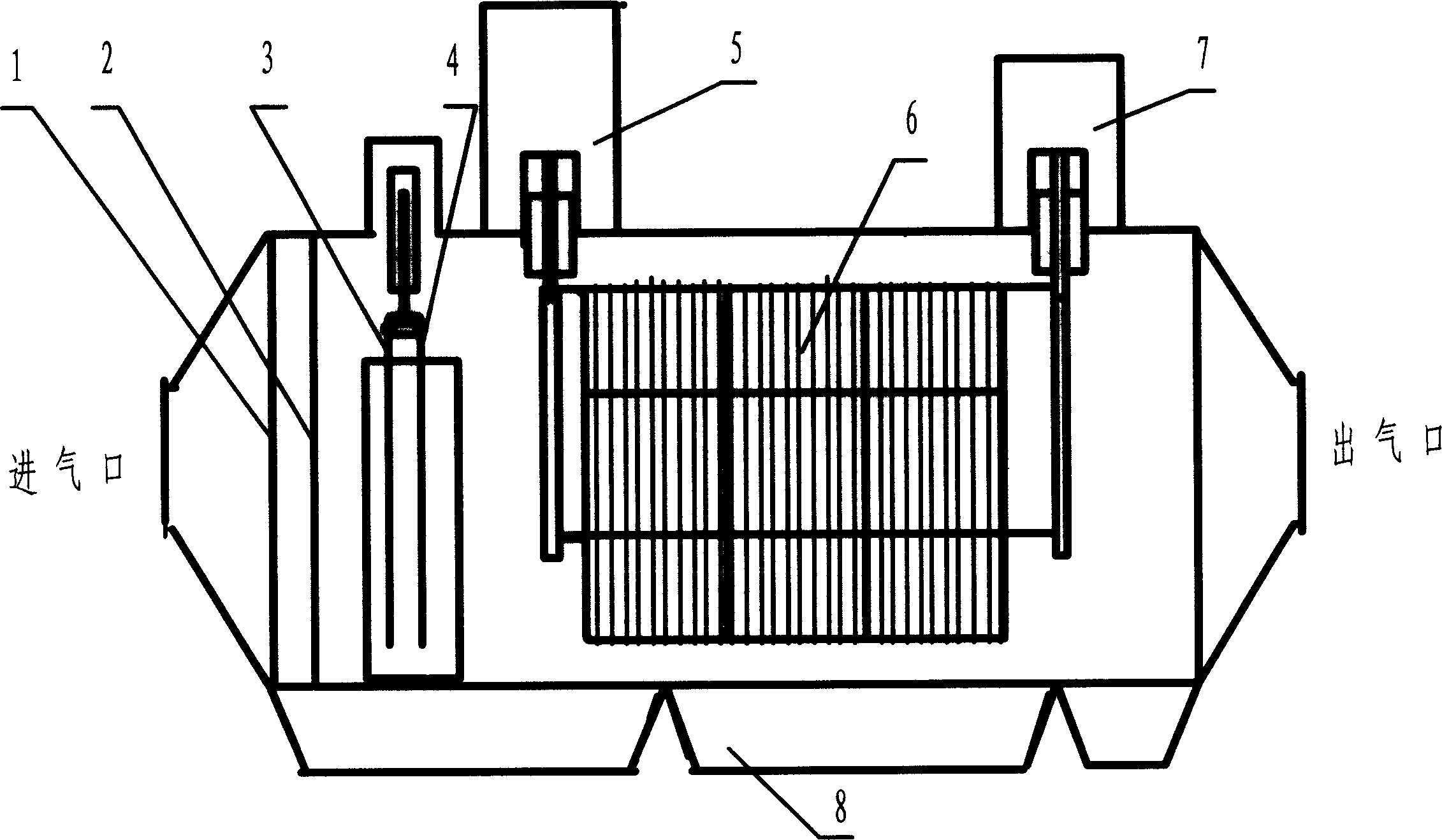

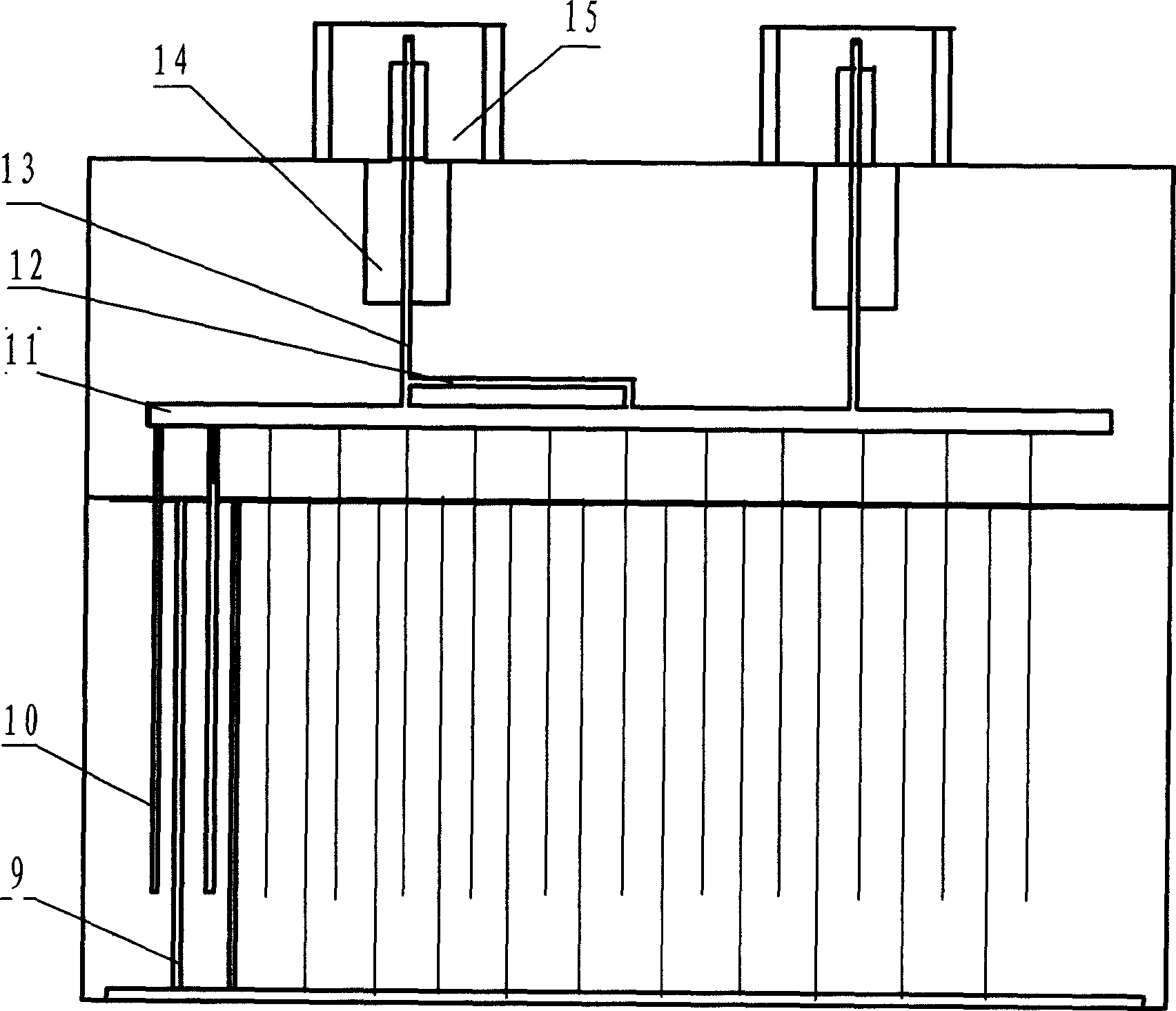

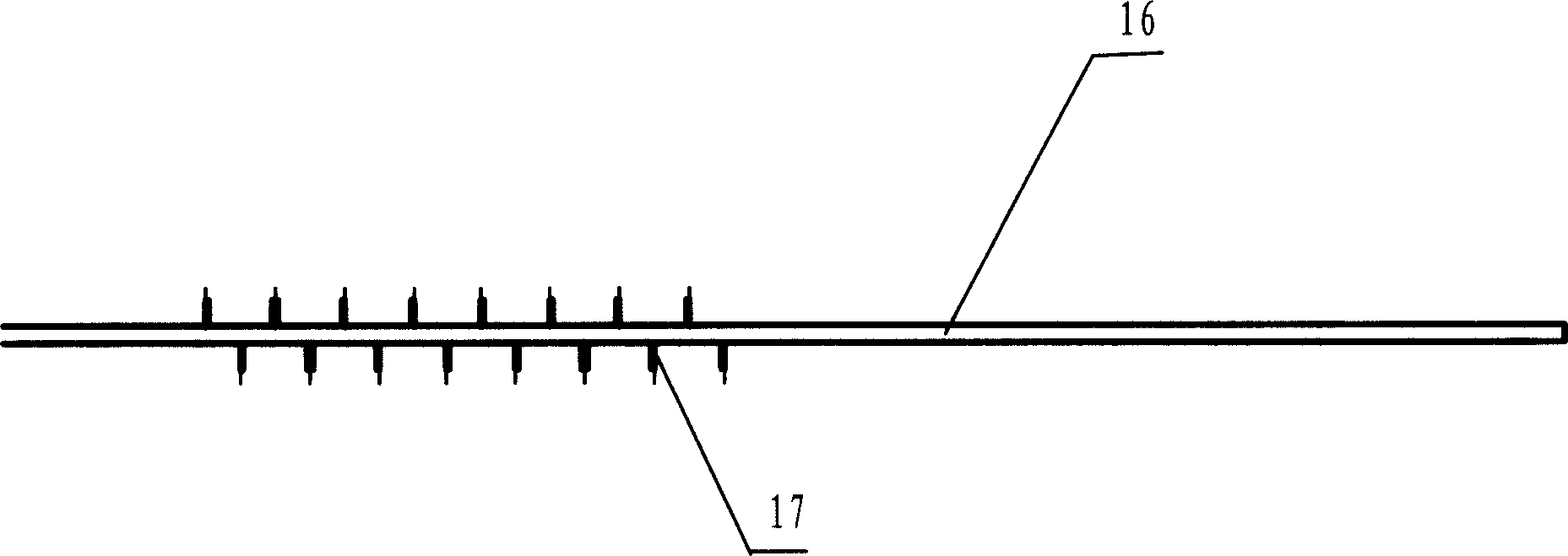

[0045] The dry pulse corona discharge flue gas purification method and device of the present invention introduce high-temperature flue gas into a humidification and cooling tower for humidification and cooling, the temperature is reduced to 50-80°C, and the water content is 5-15%; after humidification and cooling The flue gas from the flue gas enters the pulse discharge plasma reactor, high voltage is applied, the power of the pulse power supply is 50-100kW, and ammonia gas is added by the gas ammonia dosing device. The ammonia-sulfur stoichiometric ratio is 0.8:1-1:1, and the reaction forms By-product ammonium sulfate and ammonium nitrate; the by-product collector collects the generated ammonium sulfate and ammonium nitrate, and the purified flue gas is introduced into the chimney by the induced draft fan and discharged into the atmosphere.

[0046] The dry pulse corona discharge flue gas purification device of the present invention includes a flue gas humidification and cooli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com