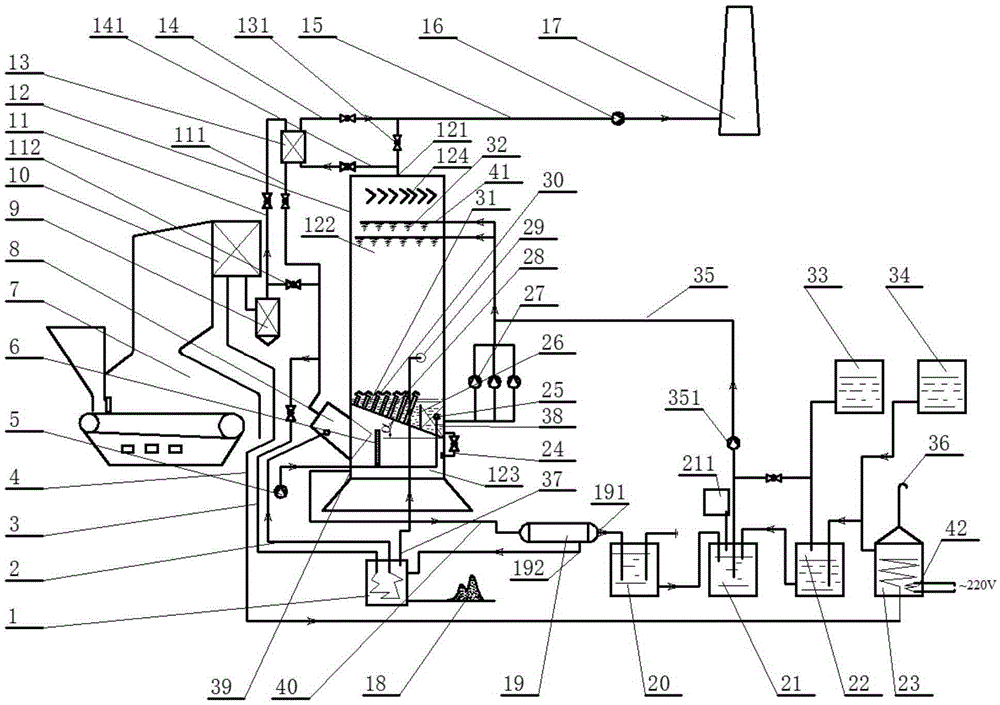

NOx and SO2 simultaneous absorption apparatus of coal-fired industrial boiler, and method thereof

An industrial boiler, SO2 technology, applied in the direction of chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of complex absorption and regeneration, difficult recovery of by-product resources, low regeneration rate of complex absorbents, etc., and achieve cost Low, convenient operation, and the effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The embodiment principle of the present invention is such:

[0031] Will NH 3 Cobalt complexes can be formed when added to an aqueous solution of cobalt salts (such as cobalt nitrate, cobalt chloride, cobalt acetate, etc.) Can be combined with residual O in industrial boiler flue gas 2 Through reaction (1) to generate similar H 2 o 2 Oxygenated bridged complexes: [(NH 3 ) 5 Co-O-O-Co(NH 3 ) 5 ] 4+

[0032]

[0033] Simultaneously, It can complex NO and convert NO from gas phase to liquid phase. The reaction is shown in formula (2):

[0034]

[0035] In the liquid phase, the complexed NO can be absorbed by the bridging compound [(NH 3 ) 5 Co-O-O-Co(NH 3 ) 5 ] 4+ Oxidation to complexed NO 2 (in [Co(NH 3 ) 5 NO 2 ] 2+ form), [Co(NH 3 ) 5 NO 2 ] 2+ Dissolved in ammonia NH 3 ·H 2 NH from O 4 NO 2 and NH 4 NO 3 .

[0036] The overall reaction of simultaneous oxidation and absorption of NO is shown in formula (3):

[0037] [(NH 3 ) 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com