Agent for desulphurization and denitration

A technology for desulfurization and denitrification, which is applied in the field of desulfurization and denitrification agents, can solve the problems of high operating costs, high ozone consumption, and inability to achieve large-scale industrialization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The actual purification effect of the desulfurization and denitrification agent described in the present invention will be described below in conjunction with specific embodiments. The embodiments described are for better illustration of the present invention and should not be construed as limiting the claims of the present invention.

[0061] Its operation method is as follows:

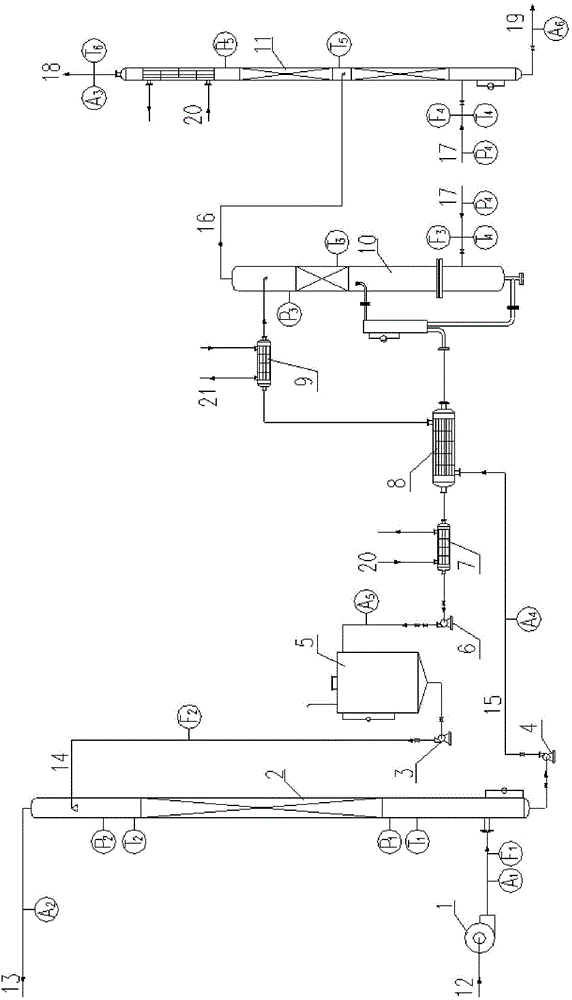

[0062]First, the desulfurization and denitrification agent of the present invention is dissolved in ethylene glycol or polyethylene glycol to form a desulfurization and denitrification solution (lean solution 14), which is injected into the lean solution tank 5, and all equipment is turned on for operation. It works like this:

[0063] Such as figure 1 Shown: the pre-purified flue gas 12 with a temperature lower than 80°C (the optimum temperature is below 35°C) enters the absorption tower 2 from the bottom after being pressurized by the booster fan 1, and at the same time, the lean liquid 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com