Honeycombed denitration catalyst taking titanium aluminum composite oxide as carrier and preparation method thereof

A composite oxide and denitration catalyst technology, which is applied in the field of honeycomb denitration catalyst and its preparation, and industrial gas purification, can solve the problem of whether the bonding force between the composite carrier and the cordierite meets the requirements of use, etc., and achieves high-efficiency denitration activity and resistance. Sulfur performance, good denitration activity, uniform distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

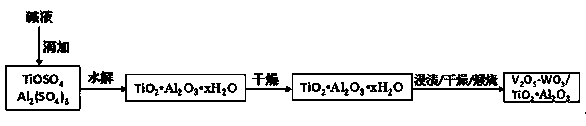

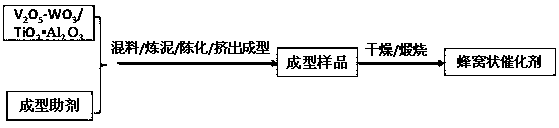

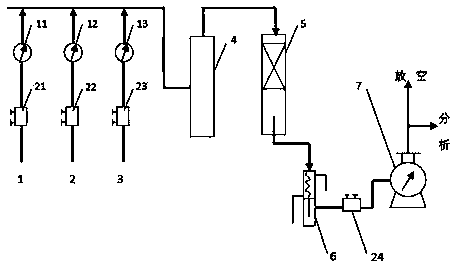

Method used

Image

Examples

Embodiment 1

[0034] (1) Get 1L of titanyl sulfate and aluminum sulfate mixed solution, the concentration of titanyl sulfate is calculated as TiO 2 Calculated as 100g / L, the concentration of aluminum sulfate is Al 2 o 3 Calculated as 15g / L. Add the mixed solution into the constant temperature reaction kettle, control the temperature in the constant temperature reaction kettle to be 55°C, and add K 2 CO 3 aqueous solution, the dropping rate is 3mL / min, and the pH value of the mixed solution in the constant temperature reactor is adjusted to 6.0. After continuing to stir at constant temperature for 1.5 h, the mixed solution in the constant temperature reaction kettle was filtered to obtain a solid. The solid matter was washed 4 times, and then dried at 80° C. for 8.0 hours to obtain a titanium-aluminum composite oxide.

[0035] (2) Take 0.3L of immersion solution, the concentration of ammonium tungstate is 92g / L and the concentration of ammonium metavanadate is 15.5g / L. Grind the titani...

Embodiment 2

[0039] (1) Get 1L of titanyl sulfate and aluminum sulfate mixed solution, the concentration of titanyl sulfate is calculated as TiO 2 Calculated as 120g / L, the concentration of aluminum sulfate is Al 2 o 3 Calculated as 20g / L. Add the mixed solution into the constant temperature reaction kettle, control the temperature in the constant temperature reaction kettle to be 60°C, and add K 2 CO 3 aqueous solution, the rate of addition is 4mL / min, and the pH value of the mixed solution in the constant temperature reactor is adjusted to 6.0. After continuing to stir at constant temperature for 1.5 h, the mixed solution in the constant temperature reaction kettle was filtered to obtain a solid. The solid matter was washed 4 times, and then dried at 100° C. for 8.0 hours to obtain a titanium-aluminum composite oxide.

[0040] (2) Take 0.3L of immersion solution, the concentration of ammonium tungstate is 115g / L and the concentration of ammonium metavanadate is 16g / L. Grind the tit...

Embodiment 3

[0044] (1) Get 1L of titanyl sulfate and aluminum sulfate mixed solution, the concentration of titanyl sulfate is calculated as TiO 2 Calculated as 100g / L, the concentration of aluminum sulfate is Al 2 o 3 Calculated as 20g / L. Add the mixed solution into the constant temperature reaction kettle, control the temperature in the constant temperature reaction kettle to be 55°C, and add K 2 CO 3 aqueous solution, the rate of addition is 5mL / min, and the pH value of the mixed solution in the constant temperature reactor is adjusted to 7.0. After continuing to stir at constant temperature for 2.0 h, the mixed solution in the constant temperature reaction kettle was filtered to obtain a solid. The solid matter was washed 4 times, and then dried at 100° C. for 8.0 hours to obtain a titanium-aluminum composite oxide.

[0045] (2) Take 0.3L of immersion solution, the concentration of ammonium tungstate is 116g / L and the concentration of ammonium metavanadate is 18g / L. Grind the tit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com