Vanadium-doped titanium-base flue gas denitration catalyst material and preparation method thereof

A catalytic material and doped technology, applied in the field of nitrogen oxide reduction catalytic materials, can solve the problems of limited popularization and application, high cost, and difficulty in obtaining pure-phase anatase structure titanium dioxide.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

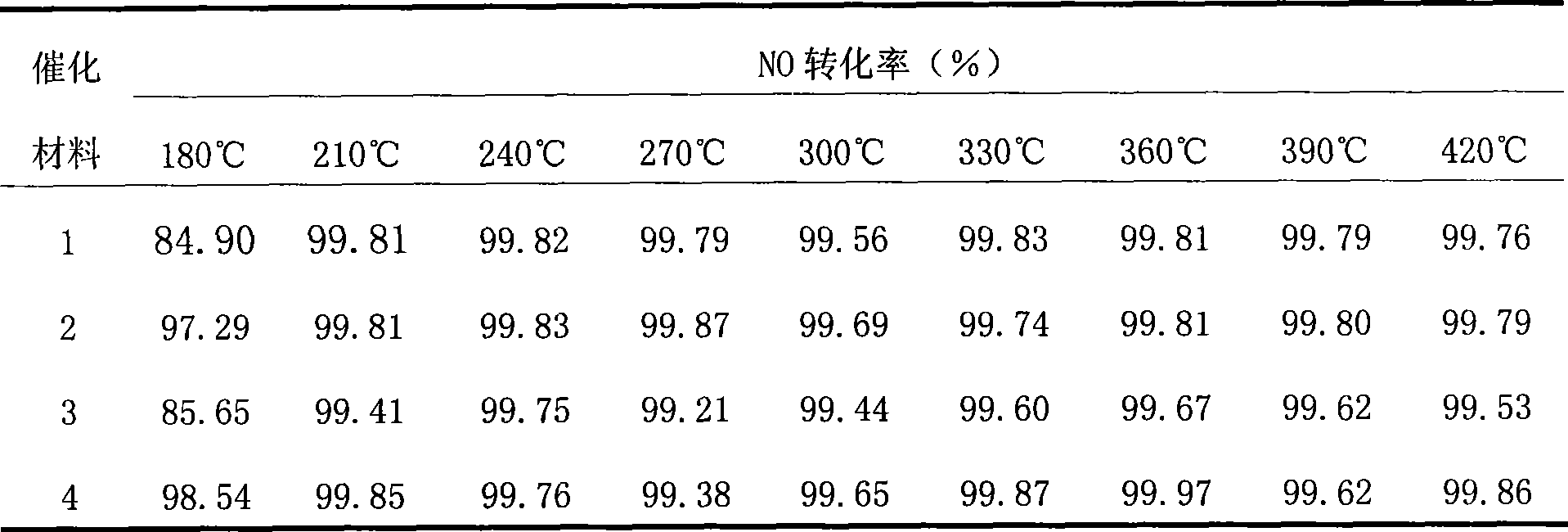

Embodiment 1

[0014] Add 1.98g of vanadium oxalate solution (2mol / L) and 2.28g of hexadecyltrimethylammonium bromide into 100g of nitric acid aqueous solution with a concentration of 1mol / L and stir at room temperature for 100 minutes to prepare liquid A; drop 30g of acetic acid into 43.92 Add 4.5 g of formamide to the above sol, stir at room temperature for 10 minutes, and put aging in a water bath at 40°C to obtain a vanadium / titanium wet gel, and the obtained wet gel was aged at the same temperature for 3 days; the wet gel was taken out and dried in an oven at 60°C for 5 days to obtain a dry gel; The xerogel was heated in a muffle furnace at a rate of 2 °C / min to 250 °C for 2 hours, and then at a rate of 2 °C / min to 450 °C for 2 hours to prepare catalyst sample 1. The specific surface area of catalytic material 1 measured by nitrogen adsorption / desorption method is 110.2m 2 / g; The catalytic material is an anatase structure as measured by X-ray diffraction.

Embodiment 2

[0016]Add 1g of polyethylene glycol (molecular weight 400) and 9.2g of vanadium oxalate solution (2mol / L) into 270g of nitric acid aqueous solution with a concentration of 0.1mol / L and stir at room temperature for 120 minutes to prepare liquid A; drop 72g of acetic acid into 102g of titanic acid Stir in butyl ester at room temperature for 30 minutes to prepare liquid B; add solution B to liquid A and stir vigorously for 20 minutes to obtain vanadium / titanium sol; add 7.5 g of formamide to the above sol, stir at room temperature for 20 minutes, and put Aging in a water bath to obtain a vanadium / titanium wet gel, and the obtained wet gel was aged at the same temperature for 3 days; the wet gel was taken out and dried in an oven at 60°C for 6 days to obtain a xerogel; the xerogel In the muffle furnace, the temperature was raised to 250°C at a rate of 2°C / min and kept for 2 hours, and then the temperature was raised to 450°C at a rate of 2°C / min for 2 hours to prepare catalyst samp...

Embodiment 3

[0018] Add 2g of polyethylene glycol (molecular weight 2000) and 4.6g of vanadium oxalate solution (2mol / L) into 270g of 0.5mol / L nitric acid aqueous solution and stir at room temperature for 120 minutes to prepare liquid A; drop 72g of acetic acid into 102g of titanic acid Stir in butyl ester at room temperature for 30 minutes to prepare liquid B; add solution B to liquid A and stir vigorously for 20 minutes to obtain vanadium / titanium sol; add 10 g of formamide to the above sol, stir at room temperature for 20 minutes, and place in a 40°C water bath aging to obtain a vanadium / titanium wet gel, and the obtained wet gel was aged at the same temperature for 3 days; the wet gel was taken out and dried in an oven at 60°C for 6 days to obtain a xerogel; In the muffle furnace, the temperature was raised to 250°C at a rate of 2°C / min and kept for 2 hours, and then the temperature was raised to 450°C at a rate of 2°C / min and kept for 2 hours to prepare catalyst sample 3. The specific...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com