Preparation of iron-based selective catalytic reduction denitration catalyst

A denitration catalyst and selective technology, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the operating cost, reaction activity operating temperature limit, equipment investment With the problems of high operating cost and large floor space, it can achieve the effect of obvious removal of impurities and hole reaming, cost reduction and high structural strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

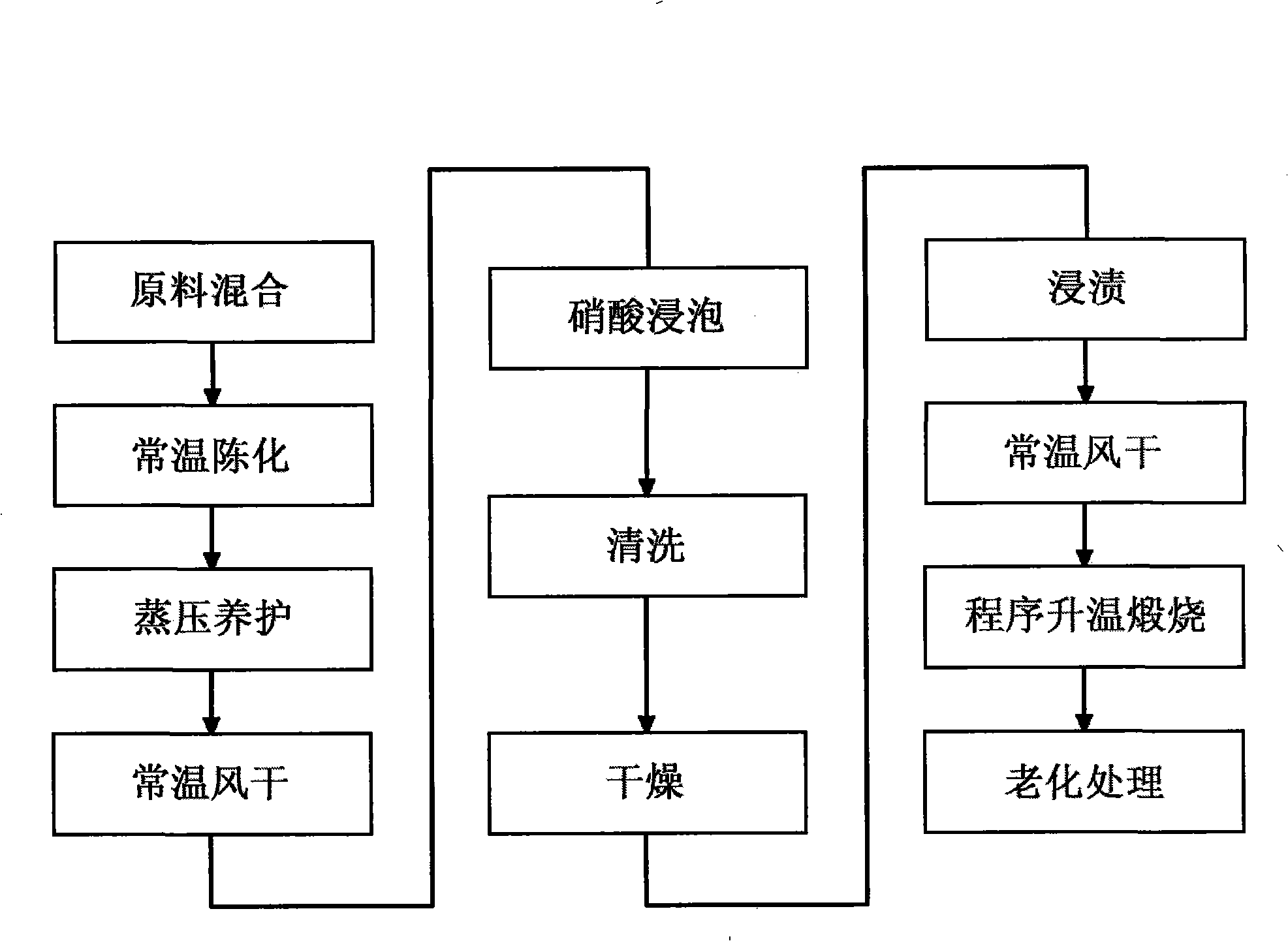

Method used

Image

Examples

Embodiment 1

[0020] The fly ash (mainly containing SiO2) in the power plant dust collector 2 -55%, Al 2 o 3 -27%), quicklime, and ordinary Portland cement are mixed at a weight ratio of 79%, 16%, and 5%, and according to the volume after mixing, they are mixed at a rate of 300g / m 3 The ratio of adding Al 2 o 3 Powder, add water and mix well, then fill into the mold. After aging at normal temperature and pressure for 1 hour, steam aging at 180°C and 10 atm for 8 hours, cold drying, crushing and sieving into particles with a particle size of 1-1.6mm.

[0021] Use mass percent concentration of 67% nitric acid to mix according to the volume-to-weight ratio of nitric acid and molded fly ash = 1ml / g, stir and soak for 1h under the condition of 50°C water bath, then rinse with deionized water until pH2 / g, the main component is: SiO 2 -79%, Al 2 o 3 -15%, which is made into a catalyst carrier.

[0022] Then measure the catalyst carrier in this example to different concentration Fe(NO 3 )...

Embodiment 2

[0026] The fly ash (mainly containing SiO2) in the power plant dust collector 2 -55%, Al 2 o 3 -27%), quicklime, and ordinary Portland cement are mixed at a weight ratio of 70%, 25%, and 5%, and according to the volume after mixing, they are mixed at a rate of 500g / m 3 The ratio of adding Al 2 o 3 Powder, add water and mix well, then fill into the mold. After aging at normal temperature and pressure for 5 hours, steam aging at 190°C and 8 atm for 12 hours, cold drying, crushing and sieving into particles with a particle size of 1-1.6mm.

[0027] Use mass percent concentration of 30% nitric acid to mix according to the volume-to-weight ratio of nitric acid and molded fly ash = 6ml / g, stir and soak for 3 hours in a water bath at 90°C, then rinse with deionized water until pH2 / g, the main component is: SiO 2 -75%, Al 2 o 3 -13%.

[0028] Then measure the catalyst carrier in this example to different concentration Fe(NO 3 ) 3 The saturation adsorption rate of the soluti...

Embodiment 3

[0032] The fly ash (mainly containing SiO2) in the power plant dust collector 2 -55%, Al 2 o 3 -27%), quicklime, and ordinary Portland cement are mixed according to the weight ratio of 70%, 16%, and 14%, and according to the volume after mixing, they are mixed according to the volume of 400g / m 3 The ratio of adding Al 2 o 3 Powder, add water and mix well, then fill into the mold. After aging at normal temperature and pressure for 2 hours, steam aging at 190°C and 8 atm for 12 hours, cold drying, crushing and sieving into particles with a particle size of 1-1.6mm.

[0033] Use mass percent concentration of 50% nitric acid to mix according to the volume-to-weight ratio of nitric acid and molded fly ash = 2ml / g, stir and soak for 3 hours in a water bath at 70°C, then rinse with deionized water until pH2 / g, the main component is: SiO 2 -78%, Al 2 o 3 -14%.

[0034] Then measure the catalyst carrier in this example to different concentration Fe(NO 3 ) 3 The saturation ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com