Ferric (III) fluoride / carbon composite material and its preparation method and application

A carbon composite material and iron trifluoride technology, applied in the field of electrochemical materials, can solve the problems of low capacity and poor conductivity of iron fluoride, and achieve the effect of increasing capacity and solving low conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

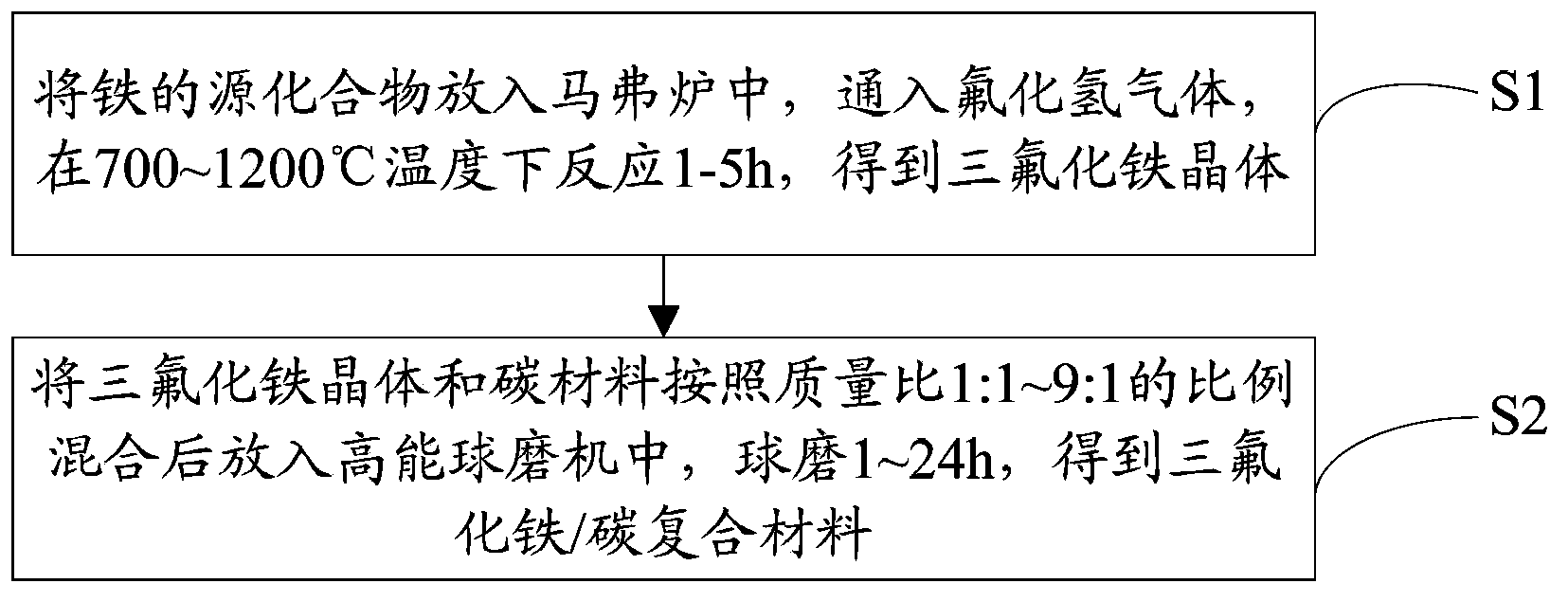

[0022] The preparation method of above-mentioned ferric trifluoride / carbon composite material, such as figure 1 shown, including the following steps:

[0023] S1. Put the source compound of iron into a muffle furnace, pass in hydrogen fluoride gas, and react at a temperature of 700~1200°C for 1-5h to obtain iron trifluoride crystals;

[0024] S2, mixing the ferric trifluoride crystal and the carbon material according to the mass ratio of 1:1 to 9:1 and then putting them into a high-energy ball mill, and ball milling for 1 to 24 hours to obtain the ferric trifluoride / carbon composite material;

[0025] In step S1 of the above-mentioned method for preparing ferric trifluoride / carbon composite material, the source compound of iron is mainly one or more of ferric chloride, ferric oxide, ferric carbonate and ferric acetate.

[0026] In the step S1 of the preparation method of the above iron trifluoride / carbon composite material, the carbon material is selected from a carbon materi...

Embodiment 1

[0043] (1) Put ferric chloride into a muffle furnace, pass in hydrogen fluoride gas, and react at a temperature of 700°C for 5 hours to obtain ferric trifluoride crystals;

[0044] (2) The specific surface area of 9g ferric trifluoride and 1g is 100m 2 / g of carbon nanotube materials were mixed into a high-energy ball mill and ball milled for 1 h to obtain a ferric trifluoride / carbon nanotube material with a mass fraction of 90% ferric chloride.

Embodiment 2

[0046] (1) Put iron oxide into a muffle furnace, pass in hydrogen fluoride gas, and react at a temperature of 1200°C for 1 hour to obtain iron trifluoride crystals;

[0047] (2) The specific surface area of 5g ferric trifluoride and 5g is 700m 2 / g of carbon nanotube material was mixed into a high-energy ball mill and ball milled for 24 hours to obtain a ferric trifluoride / carbon nanotube material with a mass fraction of 50% ferric chloride.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com