Solder stripping agent and preparation method thereof

A technology of tin stripping agent and complexing agent, applied in the field of tin stripping agent and its preparation, can solve problems such as a large amount of sludge and scrapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

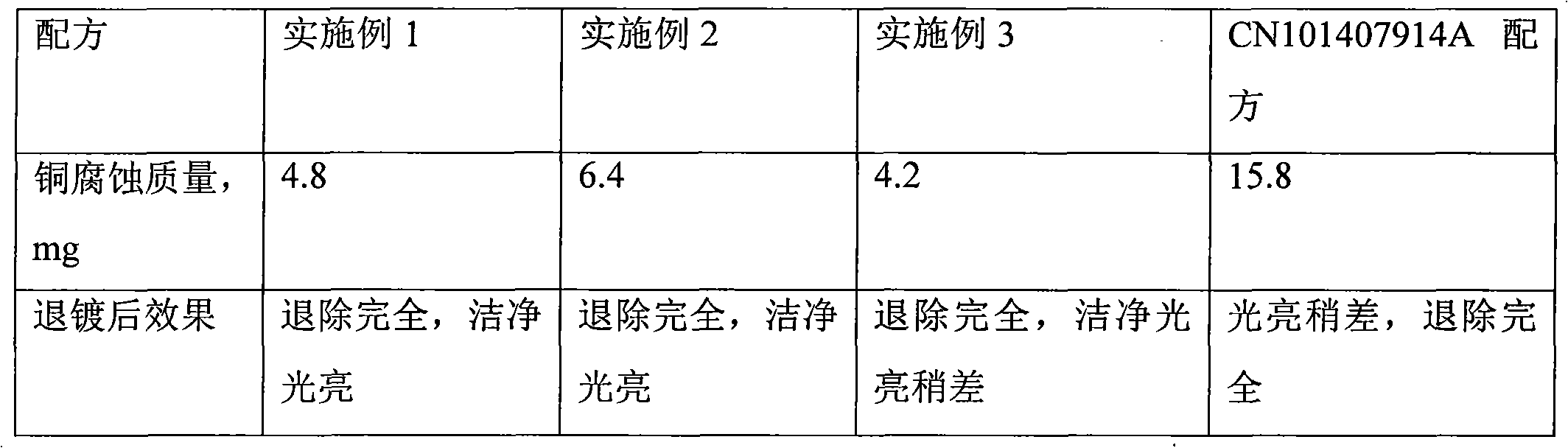

Examples

Embodiment 1

[0052] Embodiment 1 prepares a kind of tin stripping agent

[0053] The recipe is:

[0054] 70% concentrated nitric acid (volume percentage, the same below) 600g / L

[0055] FeCl 3 ·6H 2 O 8g / L

[0056] 37% hydrochloric acid (volume percentage, the same below) 60g / L

[0057] Methanesulfonic acid 4g / L

[0058] Sulfamic acid 4g / L

[0059] Monoethanolamine 10g / L

[0060] Carboxybenzotriazole 1.5g / L

[0061] Urea 1g / L

[0062] Polyethylene glycol 400 2g / L

[0063] CH 3 OH 0.5g / L

[0064] water balance.

[0065] The preparation method is:

[0066] (1) Accurately weigh monoethanolamine, add a little water, add hydrochloric acid, neutralize it, and place it for later use;

[0067] (2) dissolve ferric chloride in an appropriate amount of water, slowly add 70% concentrated nitric acid to the solution until the solution turns from reddish-brown to light green, and place it for subsequent use;

[0068] (3) Dissolve the remaining 70% concentrated nitric acid into an appropri...

Embodiment 2

[0069] Embodiment 2 prepares a kind of tin stripping agent

[0070] The recipe is:

[0071] 70% concentrated nitric acid 650g / L

[0072] FeCl 3 ·6H 2 O 8.5g / L

[0073] 37% hydrochloric acid 70g / L

[0074] Methanesulfonic acid 4g / L

[0075] Glycine 5g / L

[0076] Triethanolamine 15g / L

[0077] Benzotriazole 1.8g / L

[0078] Urea 1.5g / L

[0079] Isodecanol polyoxyethylene ether 3g / L

[0080] Ethanol 0.2g / L

[0081] water balance.

[0082] The preparation method is the same as in Example 1.

Embodiment 3

[0083] Embodiment 3 prepares a kind of tin stripping agent

[0084] The recipe is:

[0085] 70% concentrated nitric acid 600g / L

[0086] FeCl 3 ·6H 2 O 6.5g / L

[0087] 37% hydrochloric acid 50g / L

[0088] Allyl Carbonic Acid 8g / L

[0089] Sulfamic acid 5g / L

[0090] Tetrahydroxyethylethylenediamine 10g / L

[0091] Pyrrolidone 3g / L

[0092] Thiourea 1.5g / L

[0093] Nonylphenol polyoxyethylene ether 3g / L

[0094] Isopropyl alcohol 0.3g / L

[0095] water balance.

[0096] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com