A method for treating waste water from papermaking tobacco sheet production

A technology for producing waste water and tobacco flakes, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc. To deal with problems such as long process flow, to achieve the effect of reducing processing load, saving land resources, and reducing process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

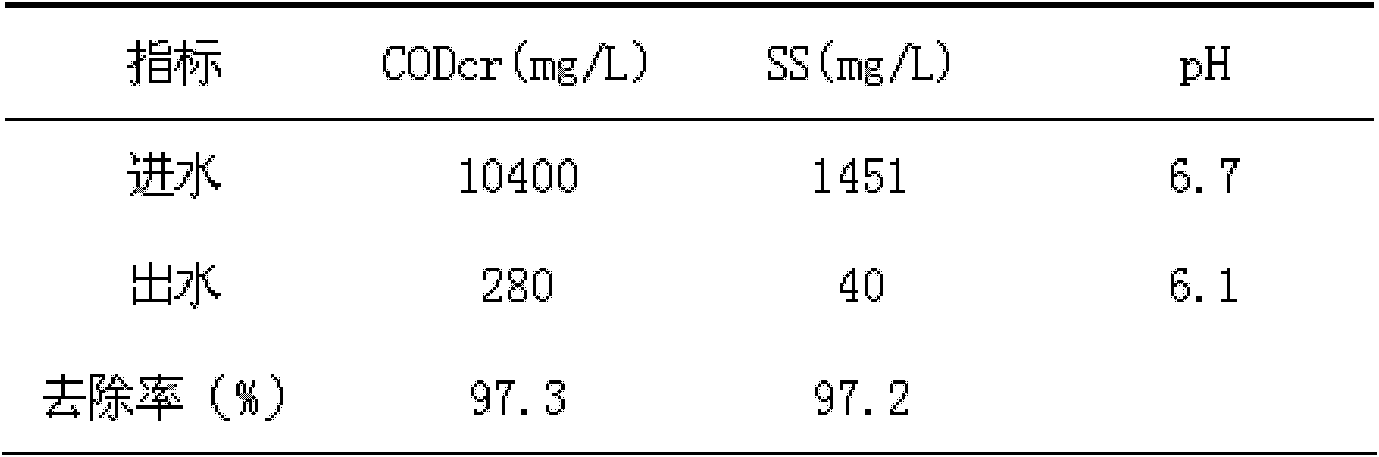

Embodiment 1

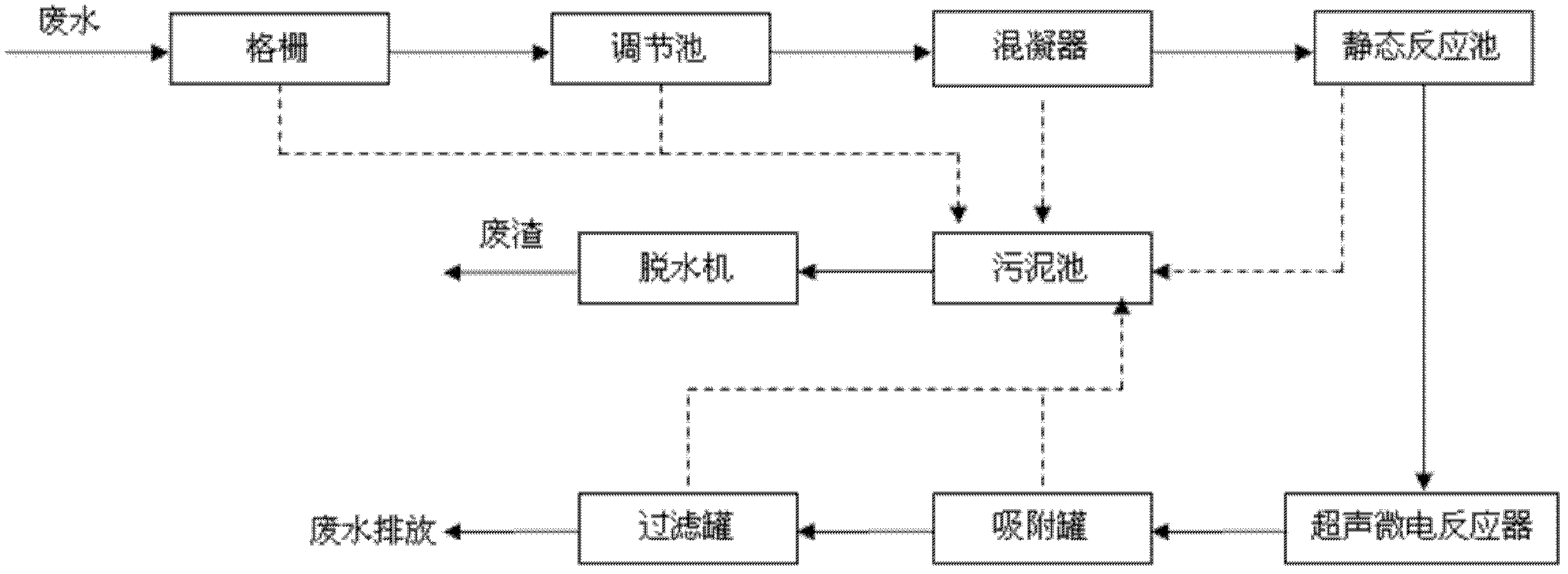

[0021] Process the waste water produced by papermaking tobacco flakes with the technical solution of the present invention, the influent water quality index is as shown in the table below, and it comprises the following steps:

[0022] (1) Pass the production waste water through the coarse filter of the grid, and cut off the suspended matter and floating matter with large particle size, and then flow into the waste water regulating tank by gravity;

[0023] (2) Lift the waste water in the waste water adjustment tank to the coagulator through the lifting pump, add Ca-diatomite composite coagulant to react for 5 minutes, then add polyferric sulfate and polyacrylamide separating agent into the static reaction tank Reaction, the reaction time is 50 minutes; after the reaction, low-concentration organic wastewater can be obtained; through this step, high-concentration wastewater with a COD (mg / l) of about 10,000 can be directly denatured into ordinary wastewater with a COD (mg / l) co...

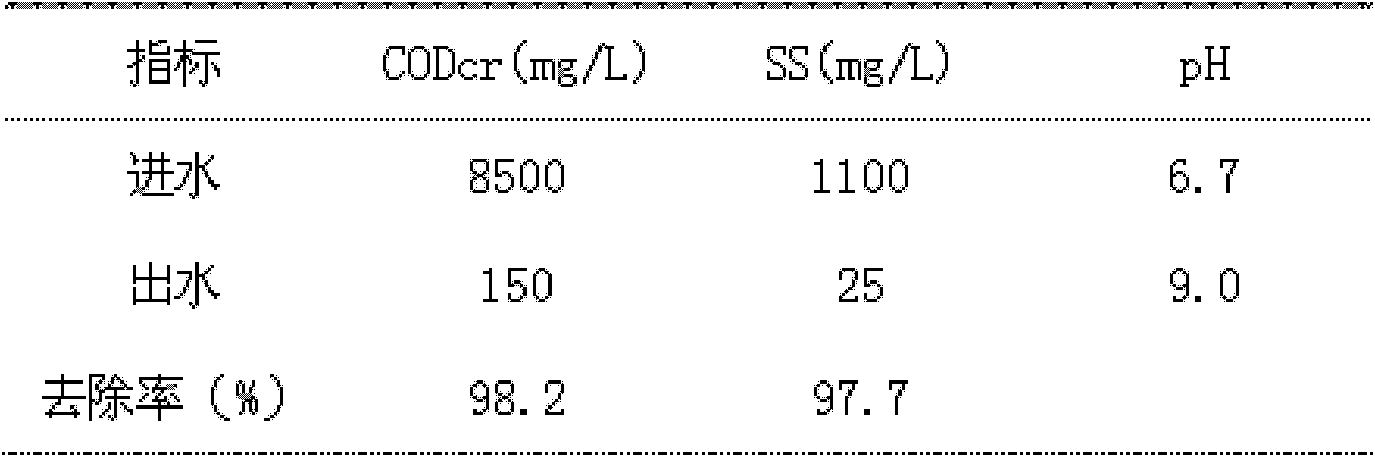

Embodiment 2

[0032] Process the waste water produced by papermaking tobacco flakes with the technical solution of the present invention, the influent water quality index is as shown in the table below, and it comprises the following steps:

[0033] (1) Pass the production waste water through the coarse filter of the grid, and cut off the suspended matter and floating matter with large particle size, and then flow into the waste water regulating tank by gravity;

[0034] (2) Lift the waste water in the waste water adjustment tank to the coagulator through the lifting pump, add Ca-diatomite composite coagulant to react for 5 minutes, then add polyferric sulfate and polyacrylamide separating agent into the static reaction tank Reaction, the reaction time is 50 minutes; after the reaction, low-concentration organic wastewater can be obtained; through this step, high-concentration wastewater with a COD (mg / l) of about 10,000 can be directly denatured into ordinary wastewater with a COD (mg / l) co...

Embodiment 3

[0042] Process the waste water produced by papermaking tobacco flakes with the technical solution of the present invention, the influent water quality index is as shown in the table below, and it comprises the following steps:

[0043] (1) Pass the production waste water through the coarse filter of the grid, and cut off the suspended matter and floating matter with large particle size, and then flow into the waste water regulating tank by gravity;

[0044] (2) Lift the waste water in the waste water adjustment tank to the coagulator through the lifting pump, add Ca-diatomite composite coagulant to react for 5 minutes, then add polyferric sulfate and polyacrylamide separating agent into the static reaction tank Reaction, the reaction time is 50 minutes; after the reaction, low-concentration organic wastewater can be obtained; through this step, high-concentration wastewater with a COD (mg / l) of about 10,000 can be directly denatured into ordinary wastewater with a COD (mg / l) co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com