Lithium ferric manganese phosphate as cathode material of lithium ion battery and preparation method thereof

A technology of lithium iron manganese phosphate and lithium-ion batteries, which is applied to battery electrodes, circuits, electrical components, etc., can solve problems such as low platform voltage, no batch protection circuits and chargers, and application restrictions, so as to reduce difficulty and improve Ion conductivity and electron conductivity, effect of battery cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

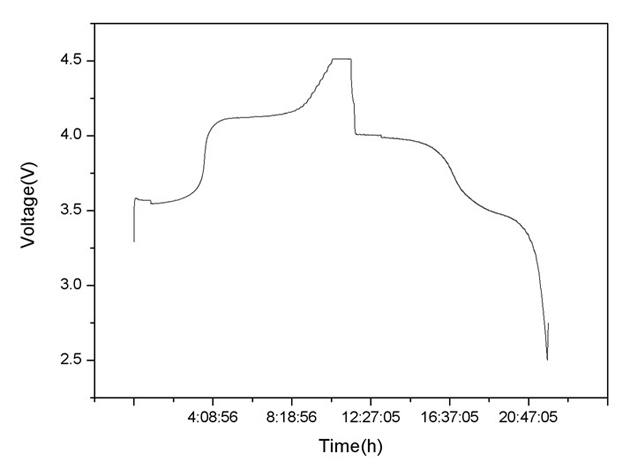

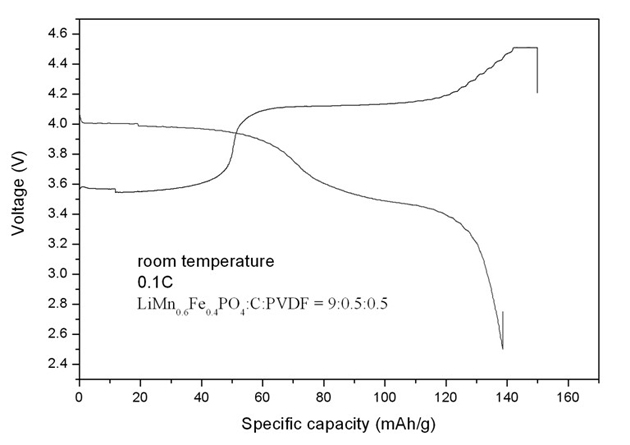

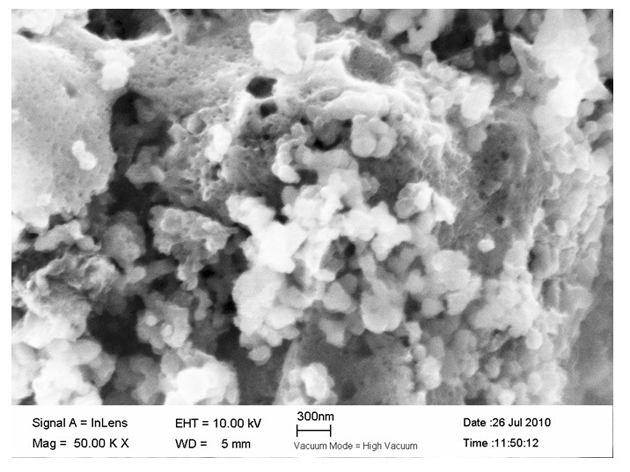

[0039] Reference attached Figure 1 to Figure 4 .

[0040] A lithium-ion battery cathode material lithium iron manganese phosphate, which has Mg doped ions, and the chemical composition of the battery cathode material lithium iron manganese phosphate is Li 0.99 Mg 0.01 Fe 0.4 Mn 0.6 PO 4 .

Embodiment 2

[0042] Reference attached Figure 1 to Figure 4 .

[0043] Lithium iron manganese phosphate lithium ion battery cathode material 0.99 Mg 0.01 Fe 0.4 Mn 0.6 PO 4 The preparation method, its preparation process: Weigh Li 2 CO 3 7.3182g, NH 4 H 2 PO 4 23.0067g, MnCO 3 13.794g, FeC 2 O 4 ·2H 2 O14.3949g, Mg(OH) 2 Place 0.1177g in a beaker, add 96mL of a mixed solution of water and ethanol, and then use a high-shear emulsifying disperser to disperse for 2h at a speed of 7.5Kr / min. Place the prepared slurry in an oven at 70°C. Dry for 10 hours, take it out and grind and put it into a crucible, then put the crucible into a muffle furnace, raise it to 450°C at a rate of 5°C / min, and pre-fire at a constant temperature for 15 hours to obtain a low-temperature lithium iron manganese phosphate material. Then add 5% polyvinyl alcohol to the low-temperature lithium iron manganese phosphate material, grind it for 1 hour, take it out and dry it and put it in a crucible, put the crucible in a muff...

Embodiment 3

[0045] Reference attached Figure 5 to Figure 8 .

[0046] A lithium-ion battery cathode material lithium iron manganese phosphate, which has Nb doped ions, and the chemical composition of the battery cathode material lithium iron manganese phosphate is Li 0.99 Nb 0.01 Fe 0.3 Mn 0.7 PO 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com