Silver nanowire preparation method

A silver nanowire, silver nitrate technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of reactor corrosion, reduce service life, increase costs, etc., to avoid pollution, The effect of reducing harshness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of the silver nanowire of the present invention comprises the following steps: (a) dissolving polyvinylpyrrolidone in ethylene glycol to obtain a polyvinylpyrrolidone ethylene glycol solution; (b) dissolving silver nitrate in ethylene glycol, Obtain silver nitrate ethylene glycol solution; (c) take anhydrous ferric chloride and dissolve it in ethylene glycol to obtain ferric chloride ethylene glycol solution; (d) add the silver nitrate ethylene glycol solution to the Polyvinylpyrrolidone ethylene glycol solution or adding the polyvinylpyrrolidone ethylene glycol solution to the silver nitrate ethylene glycol solution, stirring and mixing to obtain the first mixed solution; the mass of the polyvinylpyrrolidone and the silver nitrate The ratio is 1~9:1; (e) Add ferric chloride ethylene glycol solution and ionic liquid ethylene glycol solution to the first mixed solution respectively, stir and mix and react at a temperature lower than the boiling poin...

Embodiment 1

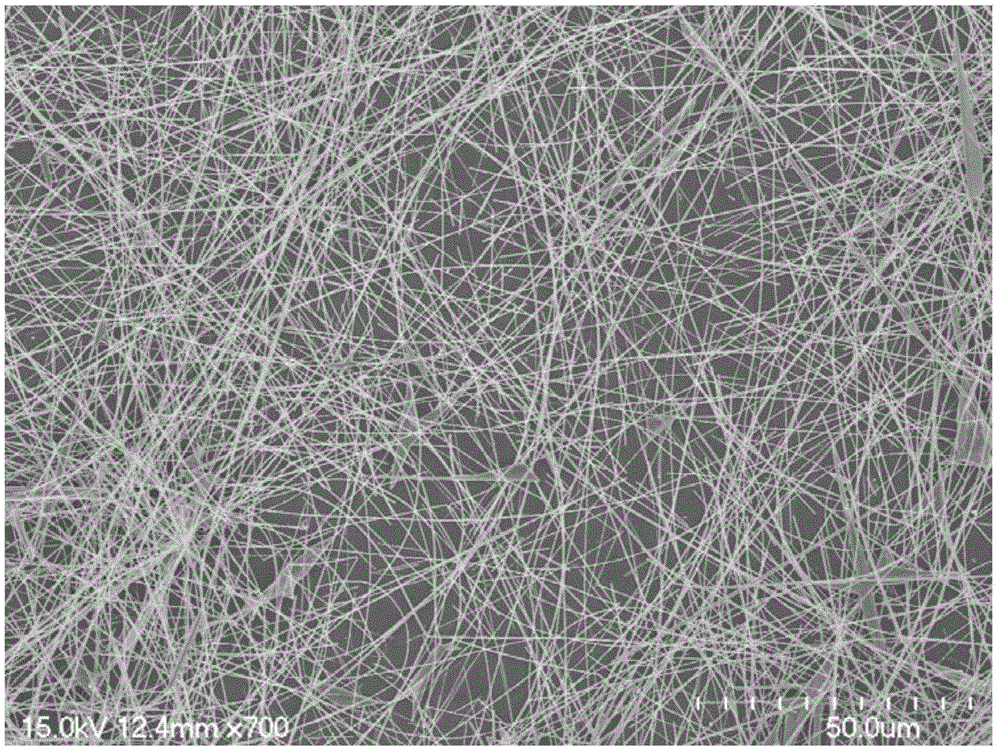

[0028] Weigh 0.1g of polyvinylpyrrolidone (PVP) and 0.1g of silver nitrate AgNO 3 Dissolve in 20ml ethylene glycol (EG) respectively, and stir well to make polyvinylpyrrolidone PVP and silver nitrate AgNO 3 Fully dissolved; then add 700 μmol / L anhydrous ferric chloride FeCl with a mass of 5 g 3 The ethylene glycol EG solution of 5 g of 700 μmol / L 1-ethyl-3-methylimidazole chloride in ethylene glycol EG solution was fully stirred and mixed. The above mixed solution was reacted at 100° C. for 16 hours, and then the reaction was terminated. The product is separated to obtain a precipitate, washed with acetone for 1 to 2 times, and then dispersed in ethanol or water to obtain the product silver nanowire, such as figure 1 shown.

Embodiment 2

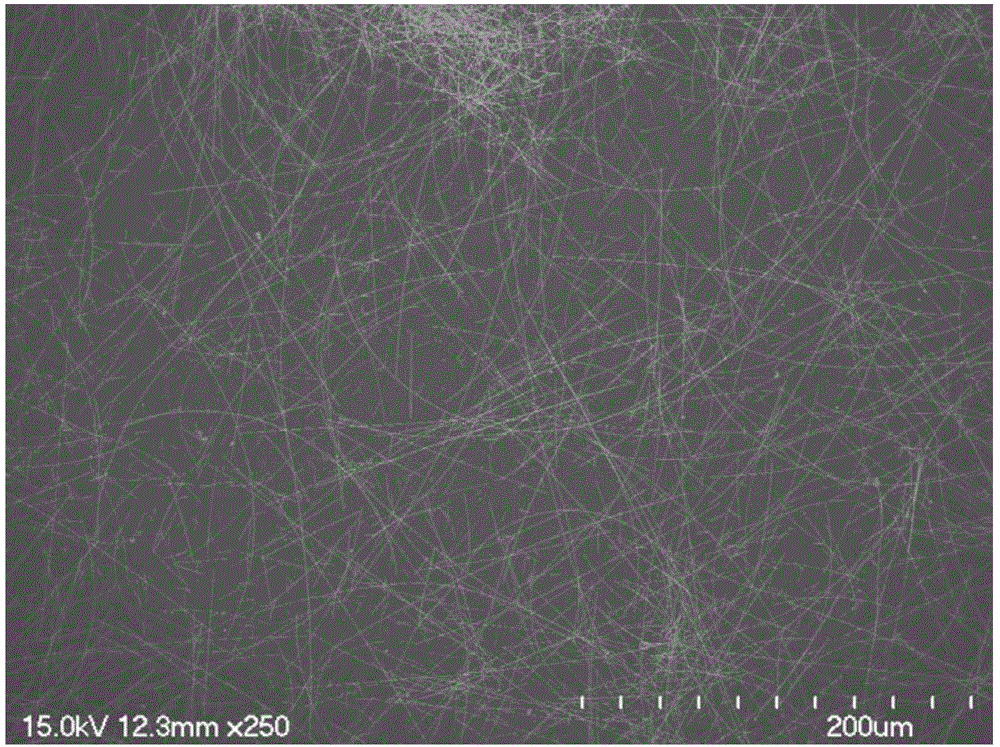

[0030] Weigh 0.5g polyvinylpyrrolidone PVP and 0.1g silver nitrate AgNO 3 Dissolve in 20ml ethylene glycol EG respectively, stir well, make polyvinylpyrrolidone PVP and silver nitrate AgNO 3 Fully dissolved; then add 500 μmol / L anhydrous ferric chloride FeCl with a mass of 7 g 3The ethylene glycol EG solution of 700 μmol / L 1-ethyl-3-ethylimidazole bromide in ethylene glycol EG solution was fully stirred and mixed. The above mixed solution was placed at a temperature of 150° C. for 17 hours, and then the reaction was terminated. The product is separated to obtain a precipitate, washed with acetone for 1 to 2 times, and then dispersed in ethanol or water to obtain the product silver nanowire, such as figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com