Method of reclaiming chemical industry products by using industrial slag containing vanadium, chromium, iron and phosphorous

A technology for chemical products and industrial slag, applied in the fields of chemical industry and environmental protection, can solve the problems of costing a lot of money and threatening the environment with waste slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

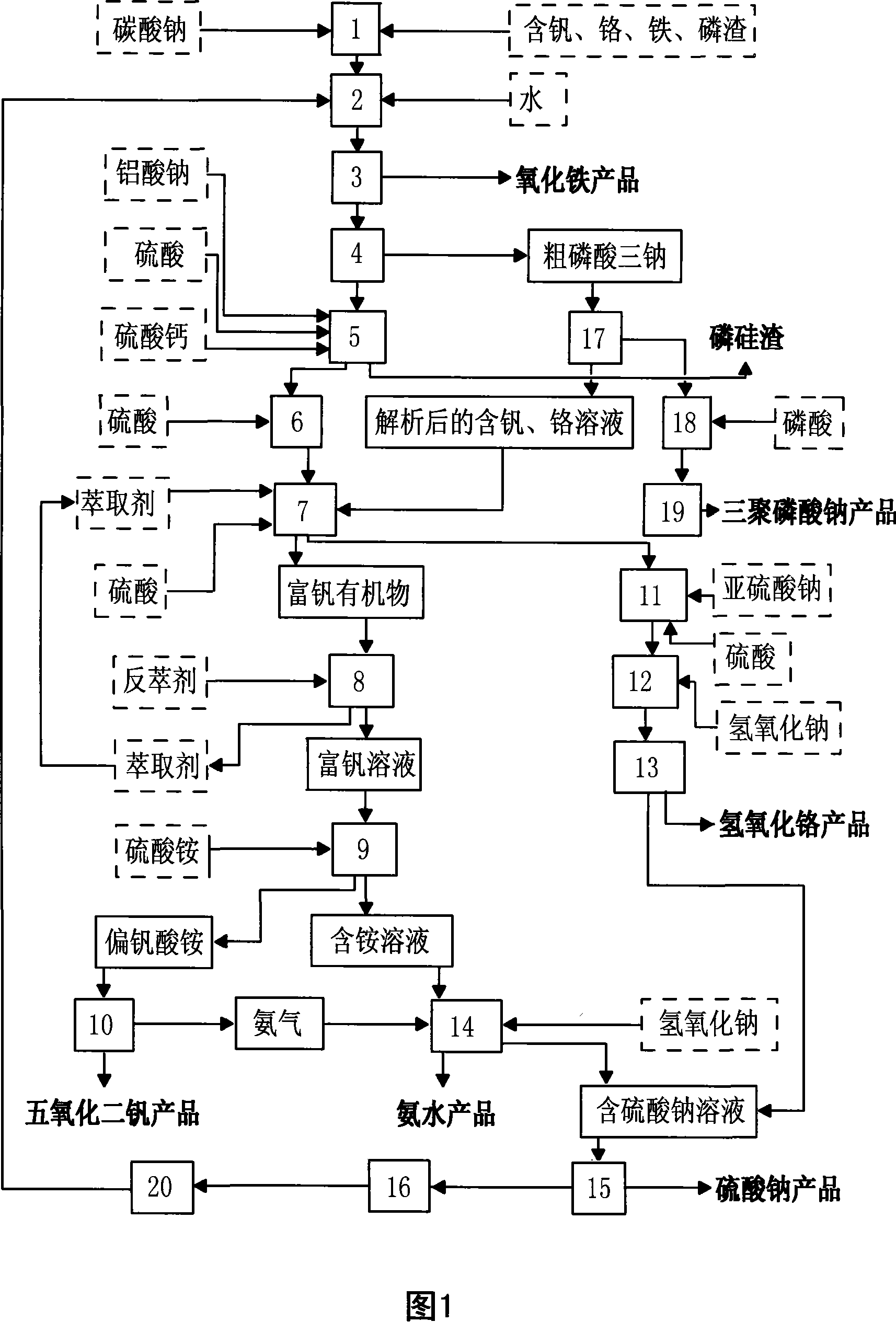

[0052] As shown in Figure 1, its extraction procedure and process are:

[0053] 1. Clinker roasting process

[0054] Crush the slag containing vanadium, chromium, iron and phosphorus through a sieve of 80-120 mesh, mix it with sodium carbonate according to the amount of vanadium, chromium, iron and phosphorus, and roast it at 800-1050°C. Phosphorus is converted into clinker which is easily soluble in water.

[0055] 2. Clinker heating and extraction process

[0056] The roasted clinker is added to hot water, and the water temperature is stirred at 80° C. for 60 to 90 minutes for leaching, so that water-soluble vanadium, chromium, and phosphorus are dissolved in the water.

[0057] 3. Separation process of iron oxide and solution containing vanadium, chromium and phosphorus

[0058] The leached clinker solid is separated from the aqueous solution in which vanadium, chromium and phosphorus compounds are dissolved by filtration, the solid part is iron oxide, and the solution i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com