Preparation method of compound photocatalyst

A catalyst and recombination light technology, applied in the field of environmental governance, can solve the problems of fast electron-hole recombination, unsatisfactory application effect, and insufficient specific surface area, and achieve the effect of reducing the band gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

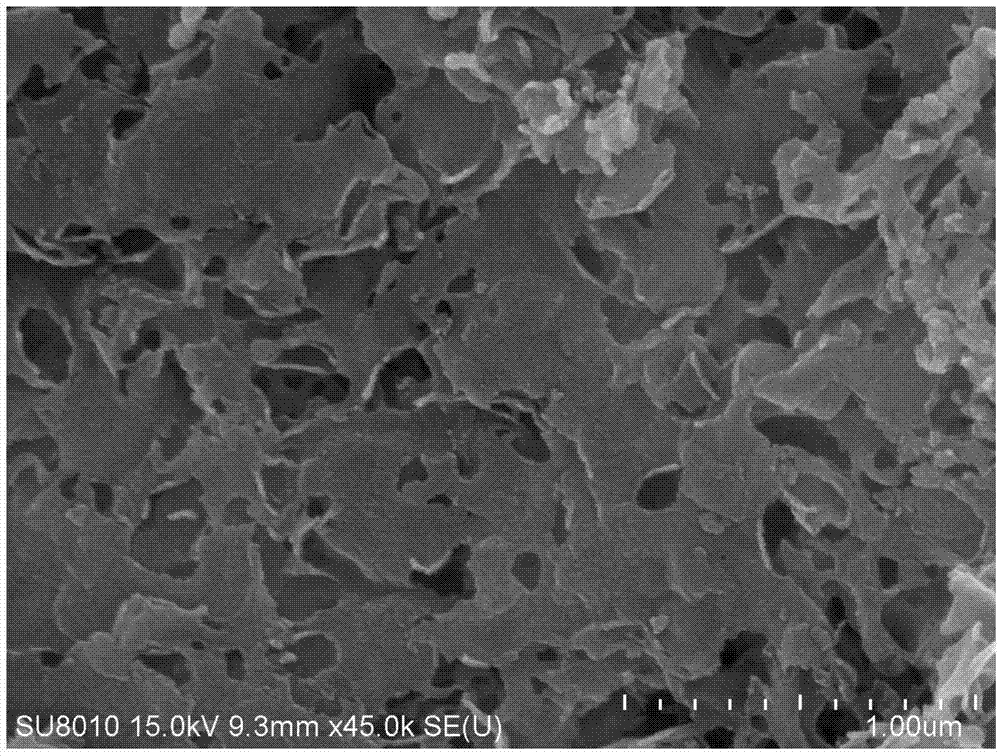

[0027] a g-C 3 N 4 / Fe 2 o 3 / montmorillonite composite photocatalyst, which is prepared by the following steps:

[0028] (1) Mix melamine 10g with H 2 O (30ml) stirring and dispersing, low speed (300r / min), add 2g ferric chloride powder in the mixture, after stirring for 20min, under the condition of high-speed stirring (800r / min), dropwise add the ammoniacal liquor that massfraction is 22wt%, drop Add until the solution pH=9.

[0029](2) Add 1g of high-purity montmorillonite (91%) high-speed stirring (800r / min) for 30min to the mixed solution of step 1), and let it stand for 5min, then the mixed solution is suction-filtered, washed to pH=7, and then Move to drying in oven, and drying temperature is controlled at 80 ℃.

[0030] (3) the melamine / Fe(OH) obtained in step 2) 3 / montmorillonite mixture (6g) is packed in the porcelain boat, spreads evenly, puts into the nitrogen stove, under N 2 Calcination under atmosphere at 500°C for 2 hours, heating rate 2°C / min, to pre...

Embodiment 2

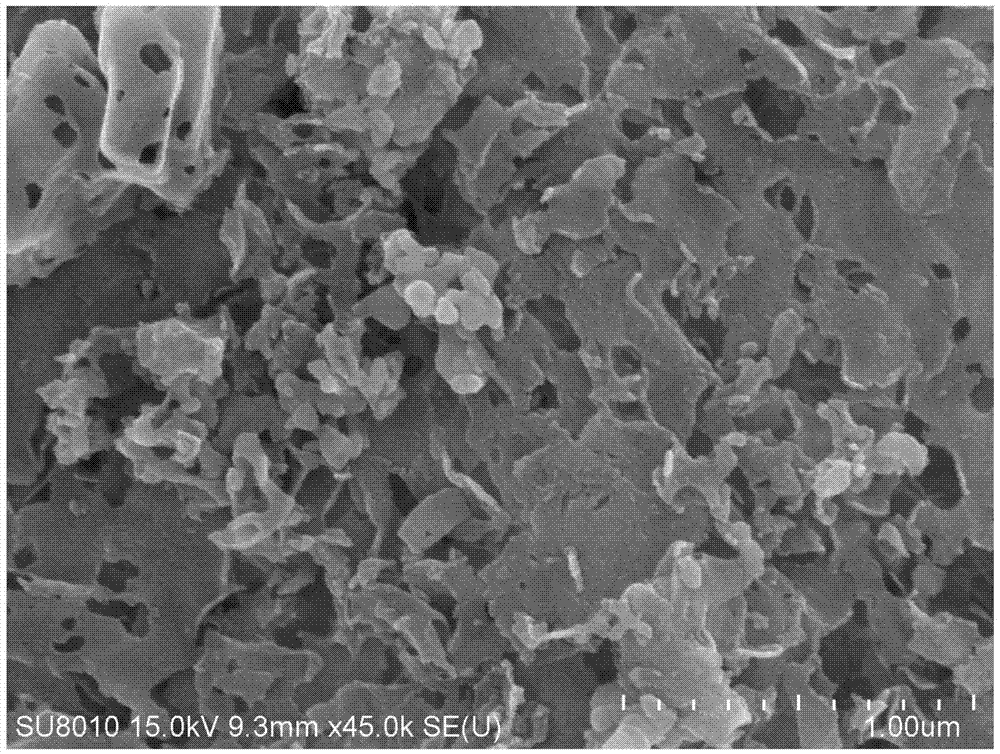

[0032] (1) Mix melamine 10g with H 2 O (40ml) stirring dispersion, low speed (400r / min), add 2.5g ferric chloride powder in the mixture, after stirring 22min, under the condition of high-speed stirring (900r / min), drip the ammoniacal liquor that massfraction is 23wt%, Add dropwise until the solution pH=9.

[0033] (2) Add 1.5g high-purity montmorillonite (92%) high-speed stirring (900r / min) for 35min to the mixed solution of step 1), let stand for 8min, then the mixed solution is suction filtered, washed to pH=8, and then It was moved to an oven for drying, and the drying temperature was controlled at 90°C.

[0034] (3) the melamine / Fe(OH) obtained in step 2) 3 / montmorillonite mixture (7g) is packed in the porcelain boat, spreads evenly, puts into the nitrogen stove, under N 2 Calcination under atmosphere at 500°C for 2 hours, heating rate 3°C / min, to prepare graphite phase carbon nitride g-C 3 N 4 / Fe 2 o 3 / Montmorillonite photocatalyst.

Embodiment 3

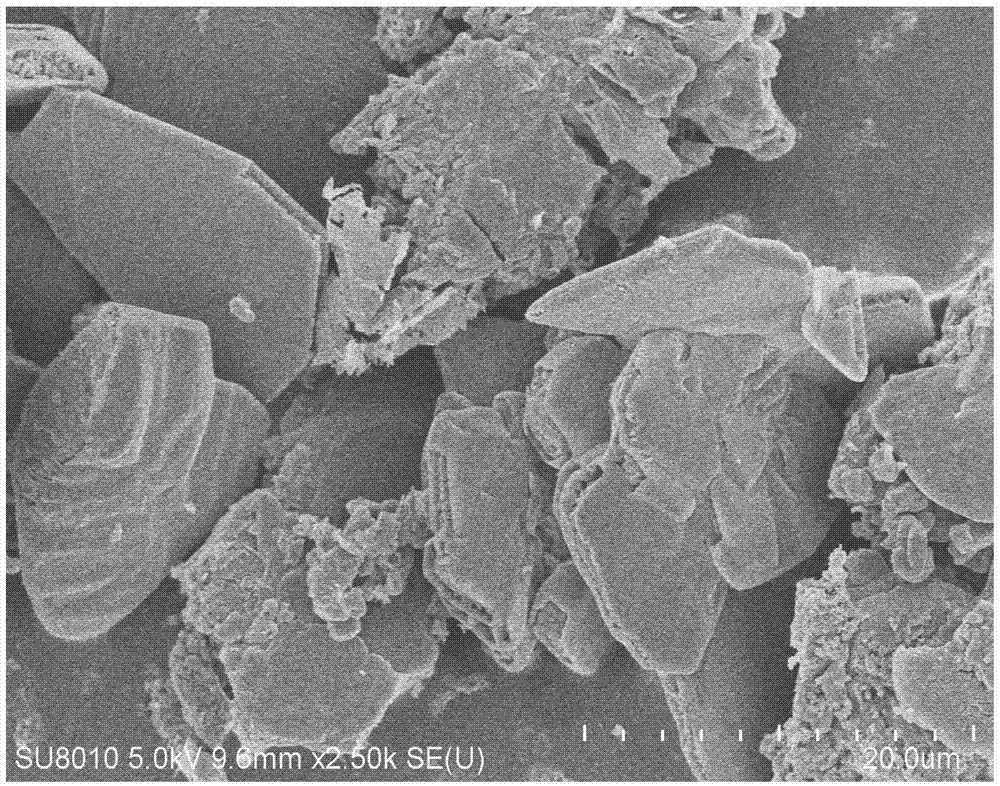

[0036] (1) Mix melamine 10g with H 2 O (50ml) stirring and dispersing, low speed (500r / min), add 3g ferric chloride powder in the mixture, after stirring for 25min, under the condition of high-speed stirring (1000r / min), dropwise add the ammoniacal liquor that massfraction is 25wt%, drop Add until the solution pH=10.

[0037] (2) Add 2g high-purity montmorillonite (95%) high-speed stirring (1000r / min) for 40min to the mixed solution of step 1), let stand for 10min, then the mixed solution is suction filtered, washed to pH=8, and then Move to drying in oven, and drying temperature is controlled at 95 ℃.

[0038] (3) the melamine / Fe(OH) obtained in step 2) 3 / montmorillonite mixture (15g) is packed in the porcelain boat, spreads evenly, puts into the nitrogen stove, under N 2 Calcination under atmosphere at 500°C for 2 hours with a heating rate of 5°C / min to prepare graphite phase carbon nitride g-C 3 N 4 / Fe 2 o 3 / Montmorillonite photocatalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com