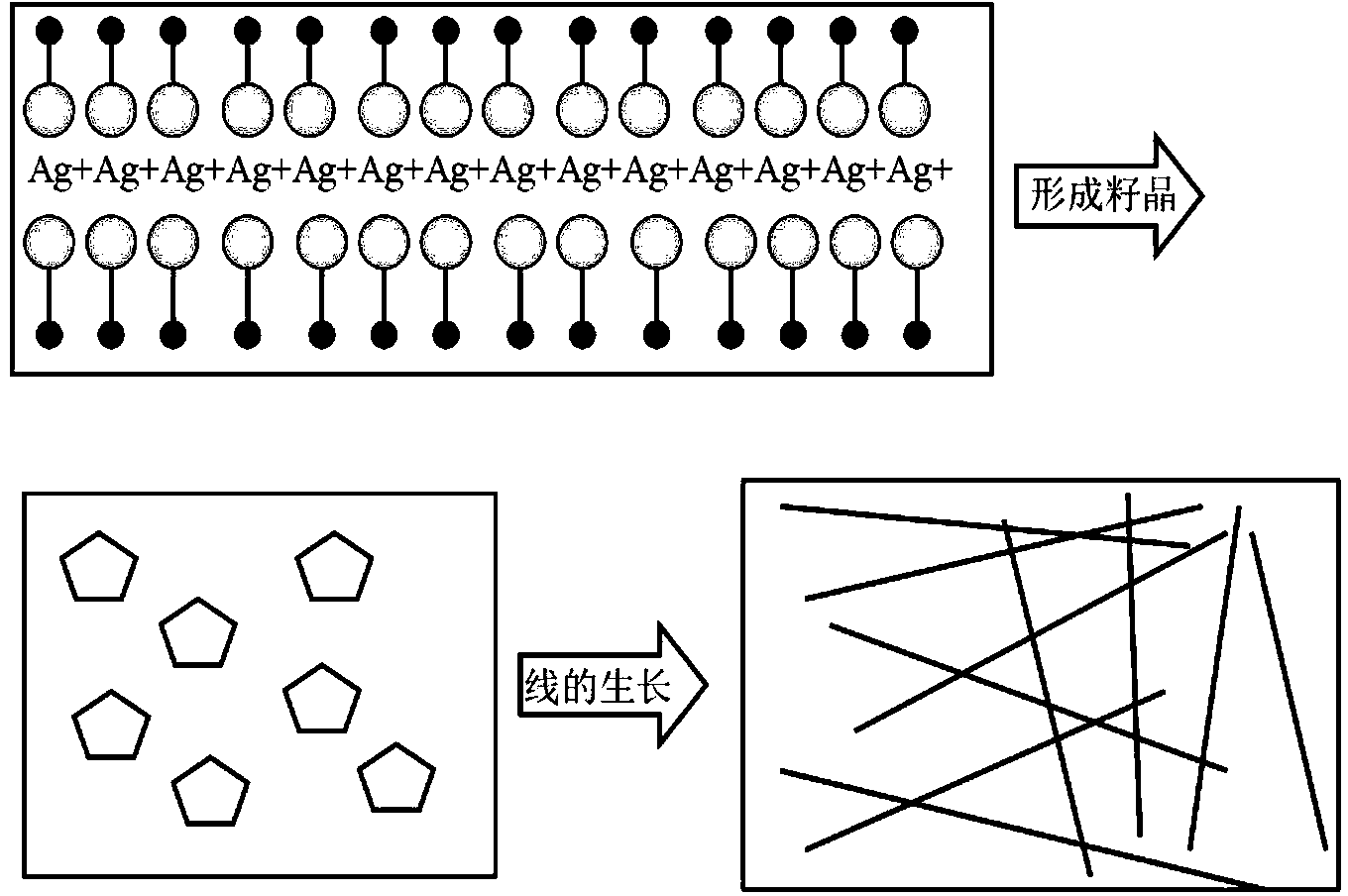

Method of adjusting and controlling length of silver nanowire by utilizing PVP (Polyvinyl Pyrrolidone) of different molecular weights and reaction temperature

A technology of silver nanowires and reaction temperature, applied in the field of nanomaterials, can solve the problems of regulating the length of silver nanowires, and achieve the effect of simple method and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Preparation of silver nanowires with a length of 25 μm:

[0020] (1) Preparation of ethylene glycol solution of ferric chloride: Dissolve 0.013g of ferric chloride in 80ml of ethylene glycol and stir evenly;

[0021] (2) Preparation of ethylene glycol solution of PVP: Weigh 0.0680g of PVP with an average molecular weight of 55000, dissolve it in 22ml of ethylene glycol solution, and stir and dissolve on a heating plate at 120°C;

[0022] (3) Preparation of ethylene glycol solution of silver nitrate: Weigh 0.1800g AgNO 3 , dissolve it in 3ml of ethylene glycol solution, and sonicate it for 10min in a sonicator to fully dissolve it;

[0023] (4) Preparation of silver nanowires: Pour the solution obtained in step (2) into a heating mantle, heat and stabilize to 120 °C, and then add a small amount of the solution obtained in step (1) and step ( 3) The prepared solution is kept for 6.5 hours to obtain silver nanowires of about 25 microns.

Embodiment 2

[0025] Preparation of silver nanowires with a length of 100 μm:

[0026] (1) Preparation of ethylene glycol solution of ferric chloride: Dissolve 0.013g of ferric chloride in 80ml of ethylene glycol and stir evenly;

[0027] (2) Preparation of ethylene glycol solution of PVP: Weigh 0.0680g of PVP with an average molecular weight of 1,300,000, dissolve it in 22ml of ethylene glycol solution, and stir and dissolve on a heating plate at 120°C;

[0028] (3) Preparation of ethylene glycol solution of silver nitrate: Weigh 0.1800g AgNO 3 , dissolve it in 3ml of ethylene glycol solution, and sonicate it for 10min in a sonicator to fully dissolve it;

[0029] (4) Preparation of silver nanowires: pour the solution obtained in step (2) into a heating mantle, heat and stabilize to 130 °C, and then add a small amount of the solution obtained in step (1) and step ( 3) The prepared solution is kept for 2.5 hours to obtain silver nanowires of about 100 microns.

Embodiment 3

[0031] Preparation of silver nanowires with a length of 50 μm:

[0032] (1) Preparation of ethylene glycol solution of ferric chloride: Dissolve 0.013g of ferric chloride in 80ml of ethylene glycol and stir evenly;

[0033] (2) Preparation of ethylene glycol solution of PVP: Weigh 0.0680g of PVP with an average molecular weight of 1,300,000, dissolve it in 22ml of ethylene glycol solution, and stir and dissolve on a heating plate at 120°C;

[0034] (3) Preparation of ethylene glycol solution of silver nitrate: Weigh 0.1800g AgNO 3 , dissolve it in 3ml of ethylene glycol solution, and sonicate it for 10min in a sonicator to fully dissolve it;

[0035] (4) Preparation of silver nanowires: pour the solution obtained in step (2) into a heating mantle, heat and stabilize to 140 °C, and then add a small amount of the solution obtained in step (1) and step ( 3) The prepared solution is kept warm for 50 minutes to obtain silver nanowires of about 50 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com