Copper, nickel and chromium-containing ferric chloride etching solution regeneration and reusing device and method

A technology of ferric chloride corrosion and equipment, applied in the direction of photography, electrodes, instruments, etc., can solve the problem of inability to meet the national discharge standard of copper, nickel, and chromium-containing wastewater that is difficult to treat, low metal element recycling rate, and sewage treatment. The problem of high cost, to achieve the effect of high degree of automation, significant economic benefits and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

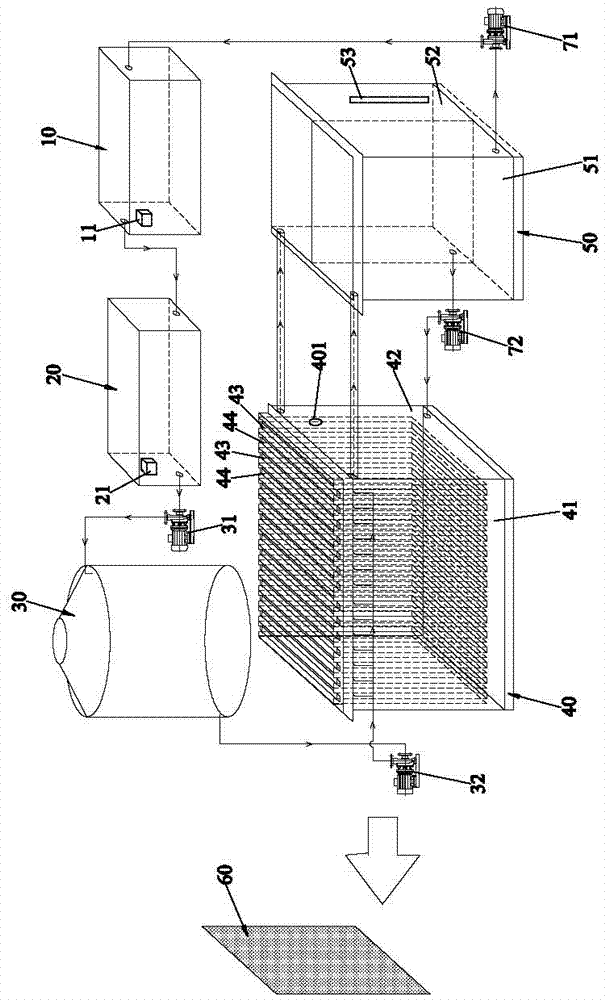

[0035] Please refer to figure 1 Shown, it has shown the concrete structure of the preferred embodiment of a kind of copper, nickel and chromium-containing ferric chloride etching solution recycling equipment of the present invention, including an etching machine 10, a waste liquid collection tank 20, A waste liquid storage tank 30 , an ion membrane electrolyzer 40 and a circulation tank 50 .

[0036] The etching machine 10 production line produces industrial ferric chloride waste liquid containing copper, nickel and chromium ions. The etching liquid parameter monitoring device 11 is installed in the etching machine 10. By testing the oxidation-reduction potential value and specific gravity of the ferric chloride etching liquid , acidity and temperature to automatically control the potion parameters of the ferric chloride etching solution in the stainless steel etching machine 10.

[0037] The waste liquid collection tank 20 communicates with the etching machine 10. Specifical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com